Unlocking Efficiency with Flue Gas Heat Exchangers

In today's climate-conscious market, one term consistently stands out: waste heat recovery. As industries strive for greater sustainability and operational efficiency, the clever use of systems like flue gas heat exchangers becomes indispensable. These devices are the key to reclaiming energy that would otherwise be lost, transforming modern industrial practices.

Understanding the Problem: Energy Loss in Industrial Processes

Industrial processes, including those in power generation and chemical processing, invariably produce waste heat. This excess energy, often carried away by exhaust gases, represents a significant opportunity for efficiency improvements. Without adequate solutions, this valuable energy dissipates into the atmosphere, contributing to increased operational costs and environmental impact. Moreover, processes lacking in efficient energy management often struggle to maintain competitive boiler efficiency and overall system effectiveness.

The Solution: State-of-the-Art Flue Gas Heat Exchangers

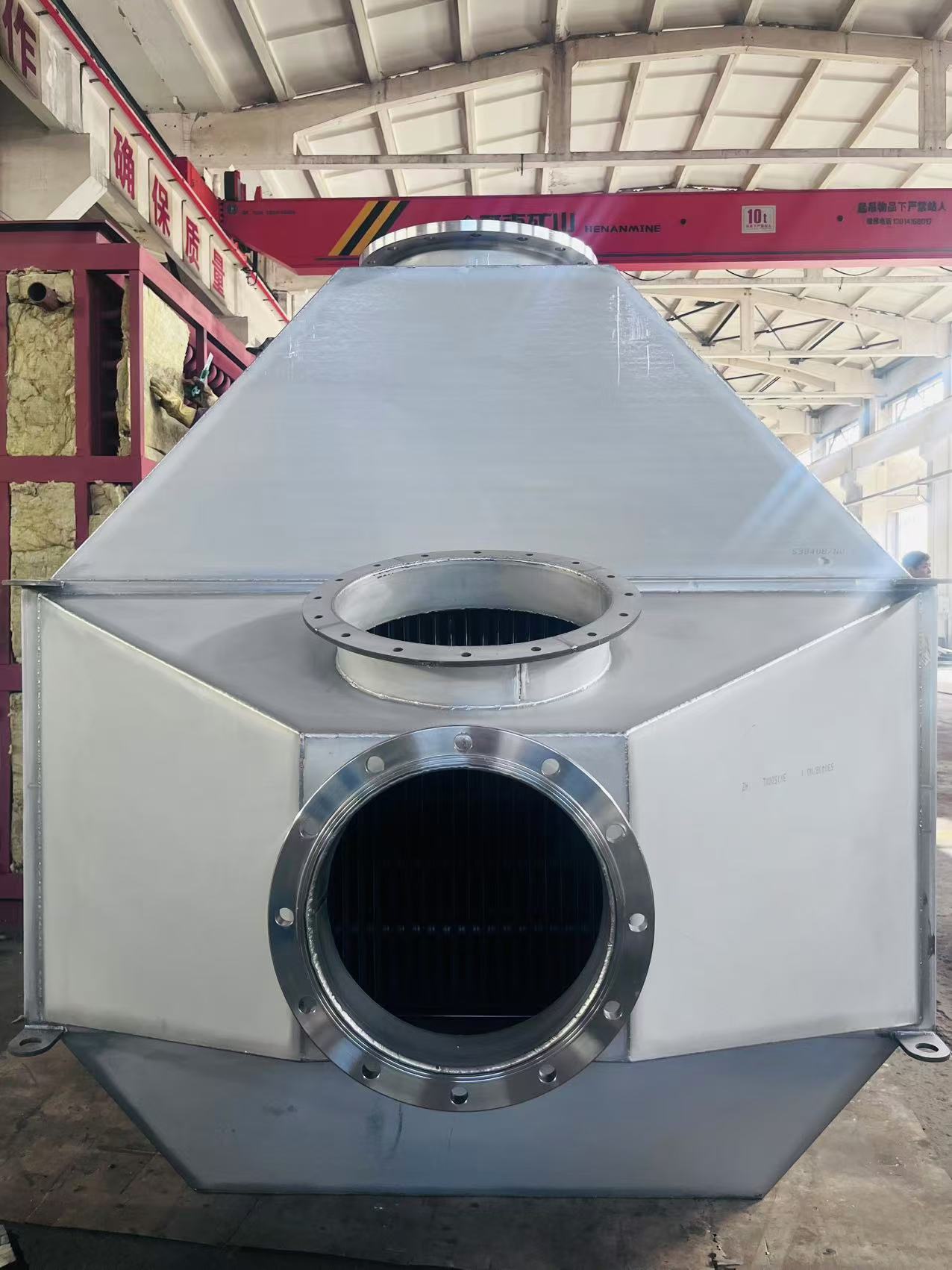

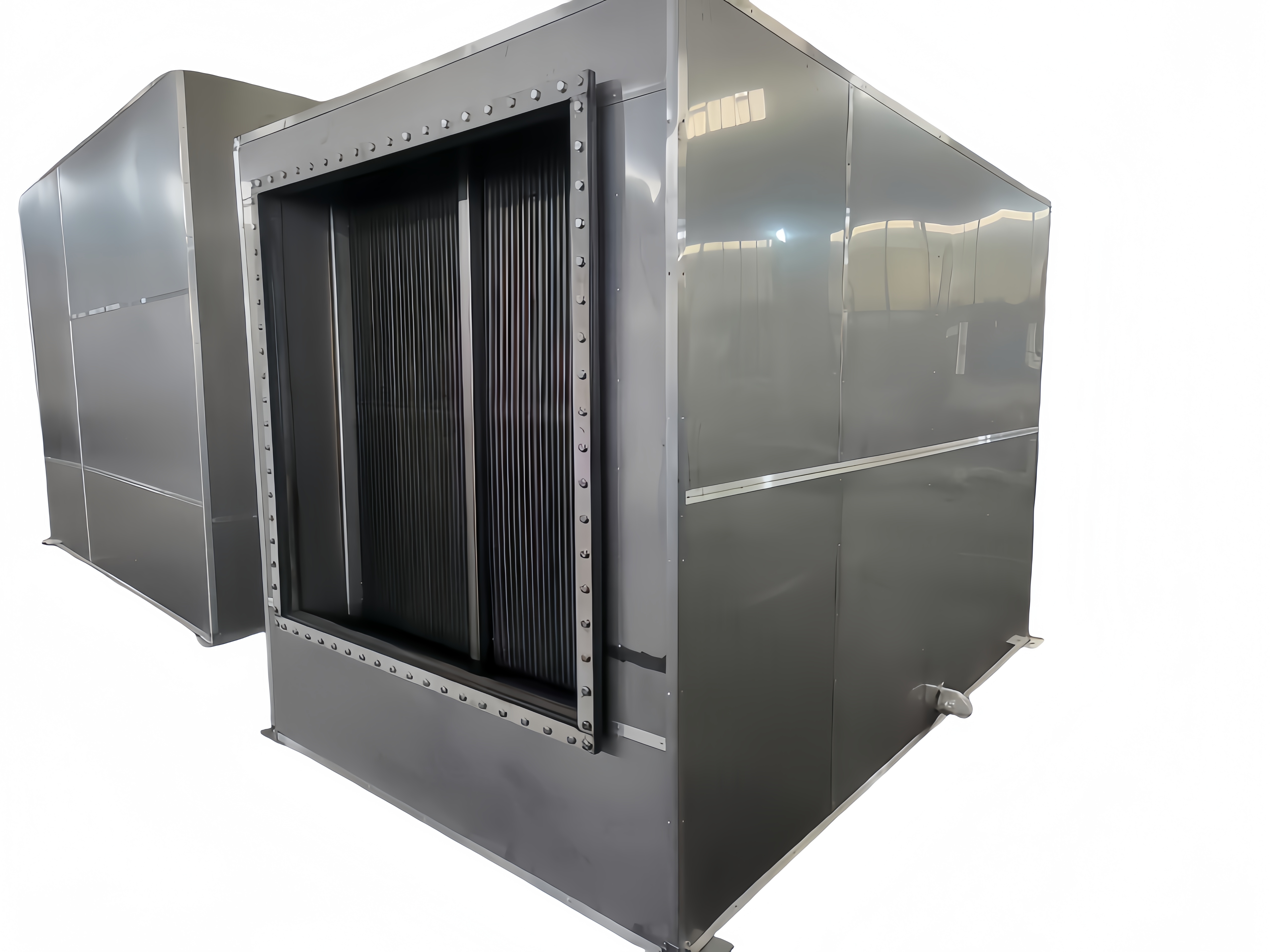

Our groundbreaking flue gas heat exchanger is engineered precisely for waste heat recovery systems. Featuring a robust, stainless steel exterior that promises durability and a sleek design, these units are crafted with geometric precision to maximize thermal transfer efficiency. Integrated seamlessly into existing systems through its cylindrical openings with flanged connections, this apparatus optimizes heat flow and exchange.

Beyond its design, the heat exchanger operates effectively even under high-pressure and high-temperature conditions, making it versatile across a variety of industrial environments. From the cleaning of combustion gas to flue gas desulfurization, our product is a testament to efficiency and sustainability. By investing in such advanced solutions, industries enhance their bottom line while making strides toward a sustainable, eco-friendly future.

Welcome to a new era of energy management, where exhaust heat recovery is not just a choice, but a pathway to ensure ecological balance and reduce operational footprints. With our heat exchanger, you embrace a commitment to power generation that is as responsible as it is powerful.