Understanding OEM Finned Tube Suppliers

OEM finned tube suppliers play a pivotal role in the manufacturing and supply chain of industries dependent on heat exchangers and thermal systems. Finned tubes are integral components in these systems, as they aid in optimizing heat transfer efficiency. If you're in search of superior quality products tailored to your specific needs, an OEM finned tube supplier is your ideal choice for unparalleled customization.

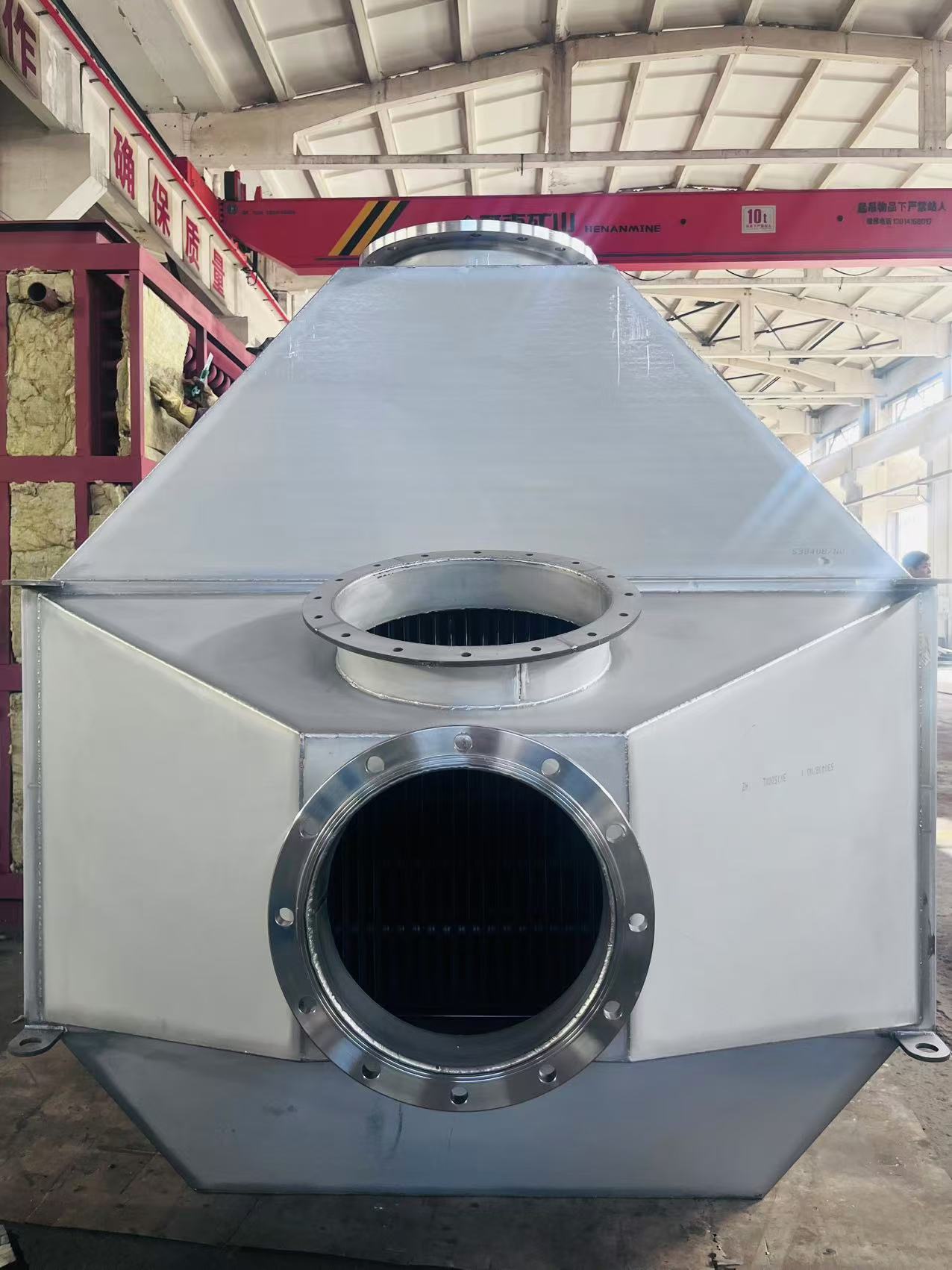

The Finned Tube Manufacturing Process

Finned tube manufacturing involves meticulous processes designed to produce highly functional and durable components. Manufacturers often use techniques such as extrusion, brazing, and welding to create fins that are integral to the tubes. This ensures that the heat transfer efficiency is maximized while maintaining structural integrity. A reputable OEM supplier will employ advanced machinery and quality control procedures to produce reliable products that meet industry standards.

Custom Finned Tube Production and Design Services

For industries requiring unique specifications, custom finned tube production is a significant advantage offered by OEM suppliers. These services allow for the design and manufacturing of finned tubes that meet precise measurements, thermal performance requirements, and material compatibility. Many suppliers provide finned tube design services to collaborate with clients on creating products that effectively address their needs, ensuring that every component functions optimally within its intended application.

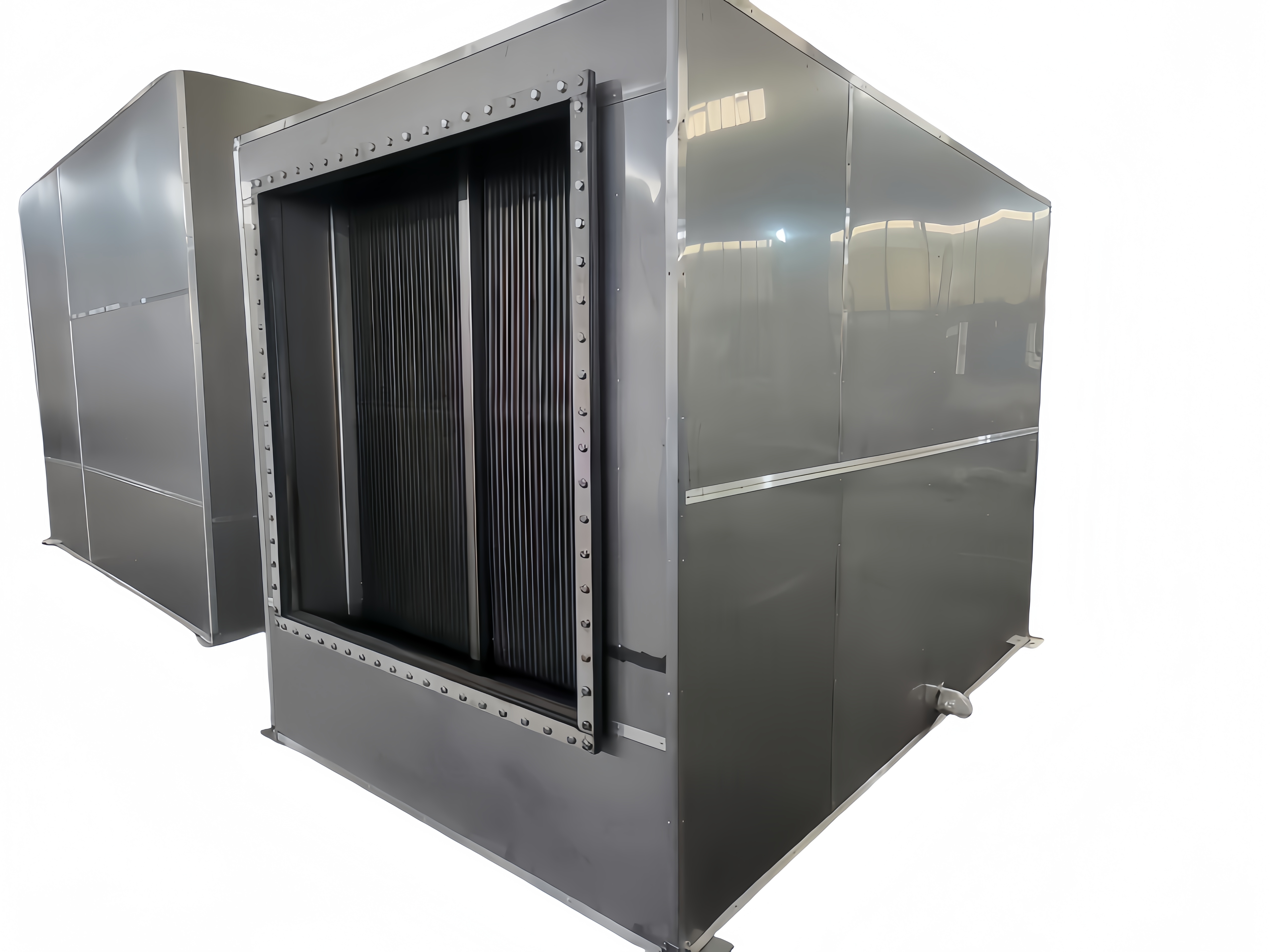

Applications of Finned Tube Heat Exchangers

Finned tube heat exchangers are widely utilized across various industries, including energy generation, HVAC systems, petrochemical production, and more. Their ability to efficiently transfer heat makes them indispensable for cooling and heating systems. Whether for air-cooled condensers or industrial heaters, finned tubes serve as the backbone in ensuring the performance and reliability of your thermal systems.

Choosing the Right Industrial Finned Tube Manufacturer

Selecting the right industrial finned tube manufacturer is critical for both cost efficiency and product quality. Look for suppliers with a proven track record in the industry, technical expertise in finned tube production, and an understanding of diverse market demands. A strong emphasis on quality assurance, flexible production capabilities, and comprehensive customer support are signs of a dependable OEM supplier.

The Importance of OEM Partnership

Partnering with an OEM finned tube supplier can provide your business with the flexibility and reliability required to meet competitive market demands. OEM suppliers offer tailored solutions that enhance the performance and functionality of thermal systems while ensuring that products align with brand expectations. These partnerships often lead to smoother operations and greater product efficiency.

In conclusion, an OEM finned tube supplier delivers unmatched customization and quality for industries needing specialized heat transfer components. By understanding the nuances of manufacturing processes, leveraging custom design services, and recognizing the critical role of these suppliers, businesses can greatly enhance their thermal systems and ensure long-lasting operational success.