Understanding the Concept of Heat Recuperators

Heat recovery systems like the Heat Recovery Gas Recuperator play a pivotal role in leveraging industrial energy efficiency. A recuperator works by capturing thermal energy from exhaust gases, which often range from 150 to 650°C, and repurposing it. This process not only supports energy conservation but also reduces harmful atmospheric emissions dramatically. Systems designed for heat recovery are vital for various industries, including petrochemicals, metallurgy, cement/glass manufacturing, and food production. These devices effectively enhance the performance of systems, such as industrial heating setups, by improving the overall energy efficiency.

Innovation in Heat Recovery: Key Features and Benefits

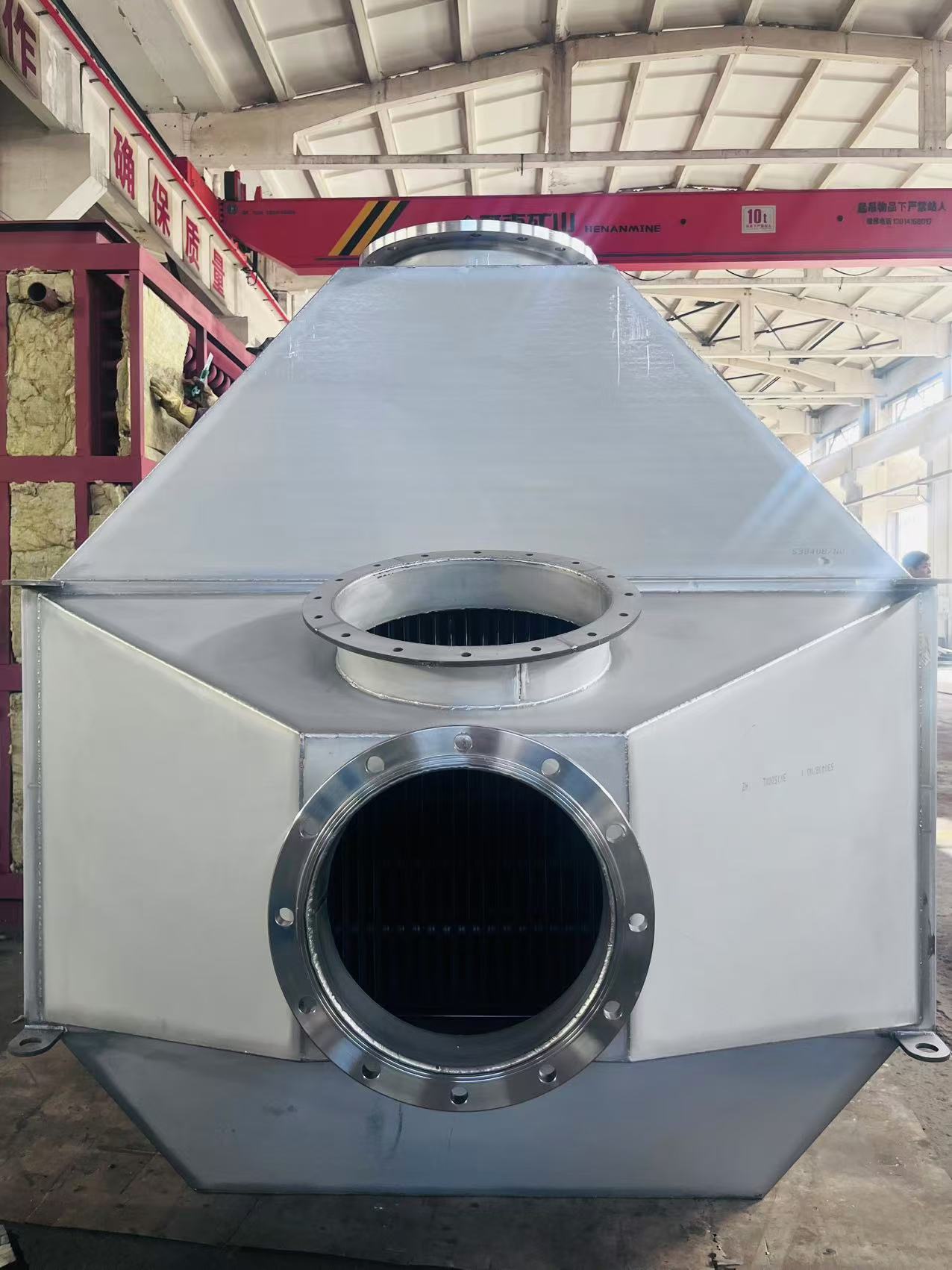

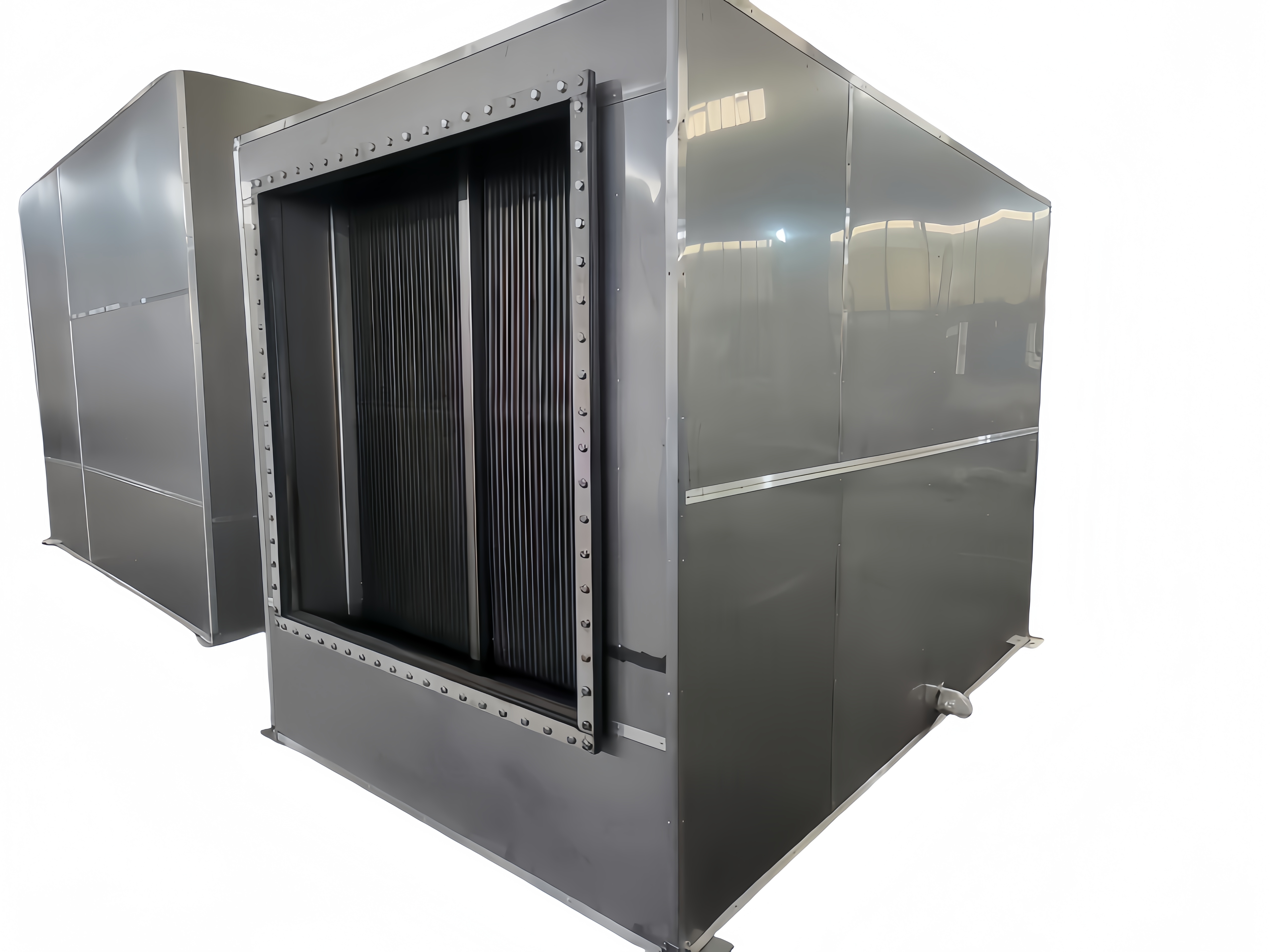

The Heat Recovery Gas Recuperator stands as a beacon of technological advancement geared for modern industrial needs. It delivers impressive results by boosting equipment performance by 15-25% and reducing fuel consumption by 10-30%. Crafted from premium stainless steel materials like AISI 321/310S, these recuperators ensure durability, seamlessly withstanding high temperatures of up to 650°C and gas pressure levels up to 5 bar.

This system's heat exchange efficiency reaches 65-85%, with the ability to lower gas temperatures by up to 300°C. Coupled with a lifecycle of 10-15 years and a return on investment within 1-3 years, these features make the Heat Recovery Gas Recuperator a practical and economical choice for enterprises. Optional features like automated cleaning systems, thermal insulation casings, real-time monitoring systems, and explosion-proof designs further enhance safety, efficiency, and convenience.

Comparison with Traditional Heating Systems

When contrasting heat recuperators with traditional heating systems, the advantages are clear. While standard heating setups rely heavily on external fuel sources, these systems tend to experience significant energy loss and higher emissions. On the other hand, recuperators advocate a sustainable approach by utilizing exhaust gases, ensuring exceptional energy efficiency and ecological benefits. Traditional systems may lack longevity and cost-effectiveness, whereas a recuperator demonstrates unparalleled durability and monetary savings, helping industries save up to 420,000 RUB annually through optimized operations.

Furthermore, recuperators contribute to global sustainability efforts by reducing harmful emissions, which is a challenge in conventional systems. These innovations cater to specific operational needs, as they are tailored in size, ranging from compact models (1.5×1×2 m) to large configurations (5×3×10 m), ensuring practicality and compatibility across industries.

Expanding Industries with Heat Energy Recuperation

The adoption of heat recovery systems signals a move towards energy efficiency and sustainability. In industries like thermal power plants, boiler facilities, and cement manufacturing, the benefits of industrial heat recovery are transformative. With the ability to handle gas flow rates from 1,000 to 50,000 m³/h, these devices suit enterprises of varying scales, from small facilities to large-scale industrial sites.

From streamlining operational costs to complying with environmental regulations through reduced emissions, recuperators ensure future-proof solutions for any company. Enhanced system design with features like bespoke dimensions and corrosion-resistant materials adds reliability to their application. All these features make recuperators not only efficient but also irreplaceable in an era where ecological technologies are more critical than ever.

In conclusion, whether you're looking to implement cutting-edge energy efficiency practices, save costs, or adopt environmentally responsible solutions, Heat Recovery Gas Recuperators offer unmatched benefits over traditional methods. Their ability to champion industrial ventilation and recuperation of energy underscores their paramount importance in revolutionizing systems of heating and energy utilization.