Understanding Finned Tube Heat Exchanger Problems

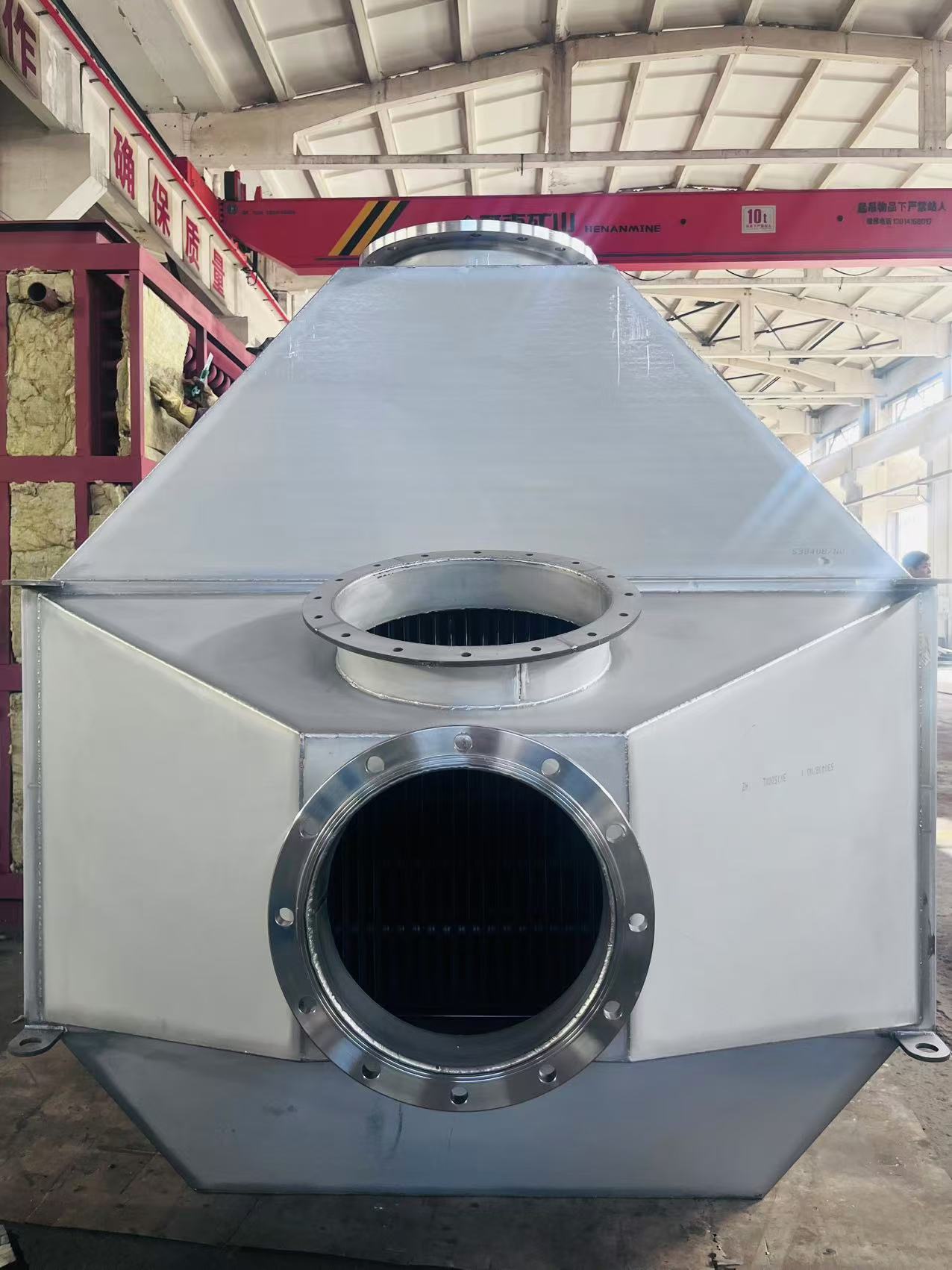

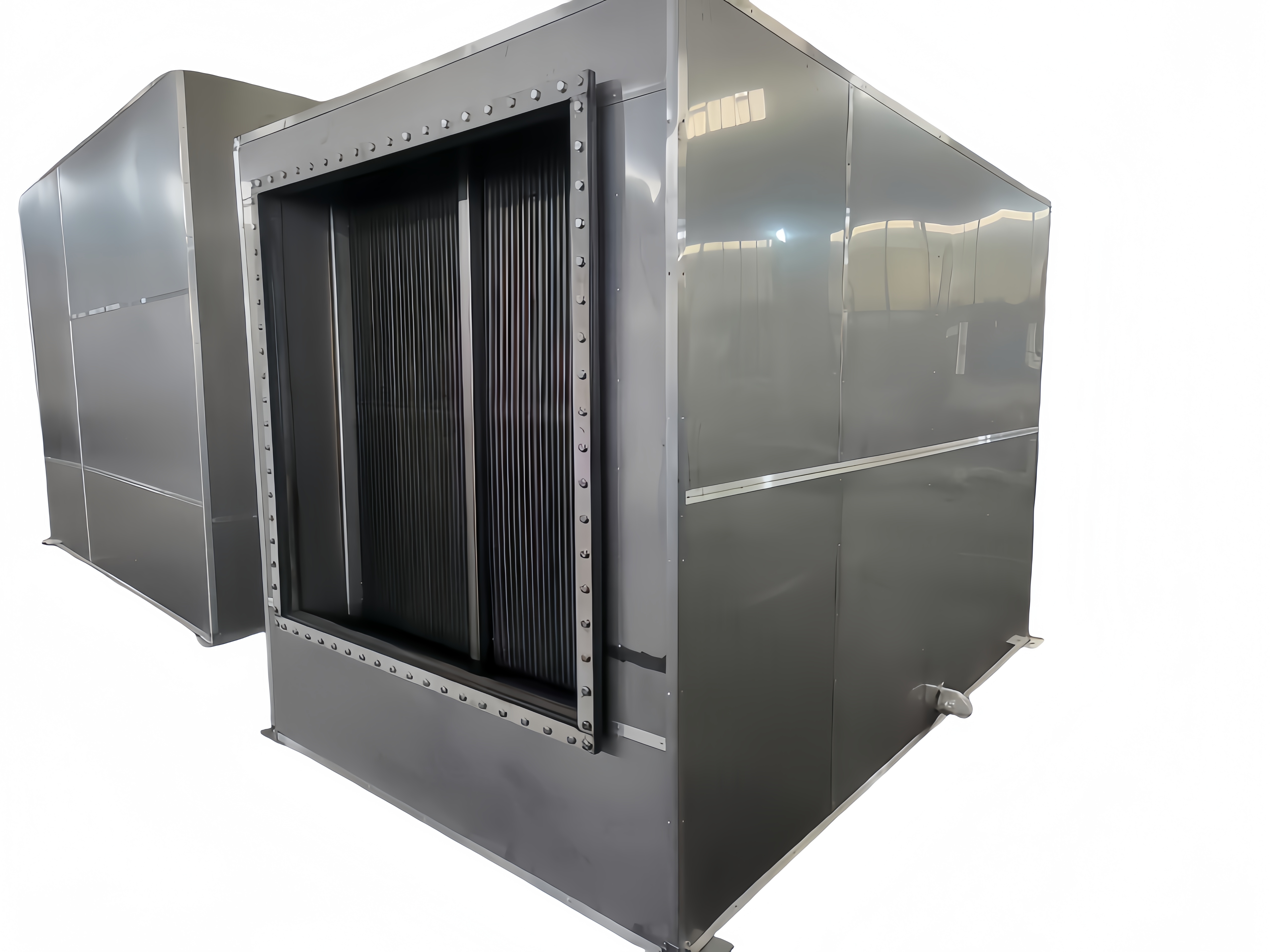

Finned tube heat exchangers stand as indispensable components in industrial cooling and heating systems, offering robust energy transfer solutions. However, like any mechanical system, they are not immune to problems. Issues with finned tube heat exchangers can manifest in various forms, from performance inefficiencies to maintenance challenges. A fundamental understanding of these potential issues is crucial for optimal functionality and extended longevity.

One of the primary concerns is the efficiency drop in finned tube heat exchangers. Factors such as fouling—where dust, oil deposits, or scale accumulate on the fins—can reduce heat transfer efficiency by up to 50%. Corrosion in finned tube heat exchangers is another frequent issue, particularly in harsh environments like chemical plants or coastal areas. Materials such as stainless steel and protective coatings like anodized aluminum are integral to combating such challenges. Regular cleaning and the use of anti-fouling coatings can mitigate these issues, ensuring the system operates at peak performance.

Addressing Structural Failures and Design Deficiencies

Structural integrity is paramount to the performance of a finned tube heat exchanger. Design failures, such as inadequate fin robustness or weak mechanical joints, can lead to significant operational setbacks. Vibration from high-flow systems and environmental factors like hail can cause fin or joint damage, reducing the overall efficiency and lifespan of the heat exchanger.

Innovative designs incorporate solutions like L-footed fins for vibration resistance, spiral fins for added strength, and vibration dampers to safeguard against mechanical wear. Furthermore, thermal optimization features such as variable-speed fans and thermal imaging technology play a significant role in maintaining uniform heat distribution and preventing hotspot formation. Proper maintenance schedules, including monthly inspections and annual pressure testing, are critical in preempting design-related defects.

Effective Maintenance Strategies

Maintenance of finned tube heat exchangers is a critical factor influencing their longevity and efficiency. Problems such as fouling, leakage, and corrosion can be significantly curtailed with a dedicated maintenance approach. The adoption of non-abrasive cleaning methods, upstream filtration systems, and anti-fouling coatings ensures minimal downtime and sustained efficiency.

Leakage in finned tube heat exchangers is another concerning issue, often arising from thermal fatigue due to repeated heating and cooling cycles. This can be addressed through the use of bimetallic fin-tube bonds and expansion joints, which help counteract damage from extreme temperature changes. Drainage valves and antifreeze coatings are essential in preventing freeze damage, especially in cold climates or cryogenic applications.

Expanding Operational Capabilities

Modern advancements in finned tube heat exchangers focus on enhancing durability and expanding operational capabilities in demanding environments. High-performance materials such as titanium and corrosion-resistant alloys ensure resilience against extreme conditions, while innovative features like glycol solutions and heating tapes maintain seamless functionality in subzero temperatures.

Thermal optimization, achieved through precise fin spacing and predictive maintenance tools, enables industries to maximize performance and minimize maintenance costs. In industrial setups like chemical plants, HVAC systems, and power plants, these sophisticated engineering solutions are not merely a luxury but a necessity for tackling a wide array of operational challenges.

In conclusion, finned tube heat exchanger defects can pose significant obstacles to industrial applications. However, leveraging advanced materials, robust designs, and proactive maintenance strategies can effectively address these issues. By understanding the intricacies of these systems and implementing innovative solutions, industries can ensure long-term efficiency, reliability, and serviceability for their equipment.