Understanding Recuperative Heat Exchangers

Recuperative heat exchangers are innovative solutions designed to revolutionize industrial processes by harnessing waste heat from exhaust gases. These systems find their essential place amid high-intensity logistics and production environments, such as ports with vast storage zones and container cranes. The core component of this technology is its ability to facilitate energy saving and the reduction of operational costs by effectively utilizing heat recirculation.

The Functionality of Recuperative Heat Exchangers

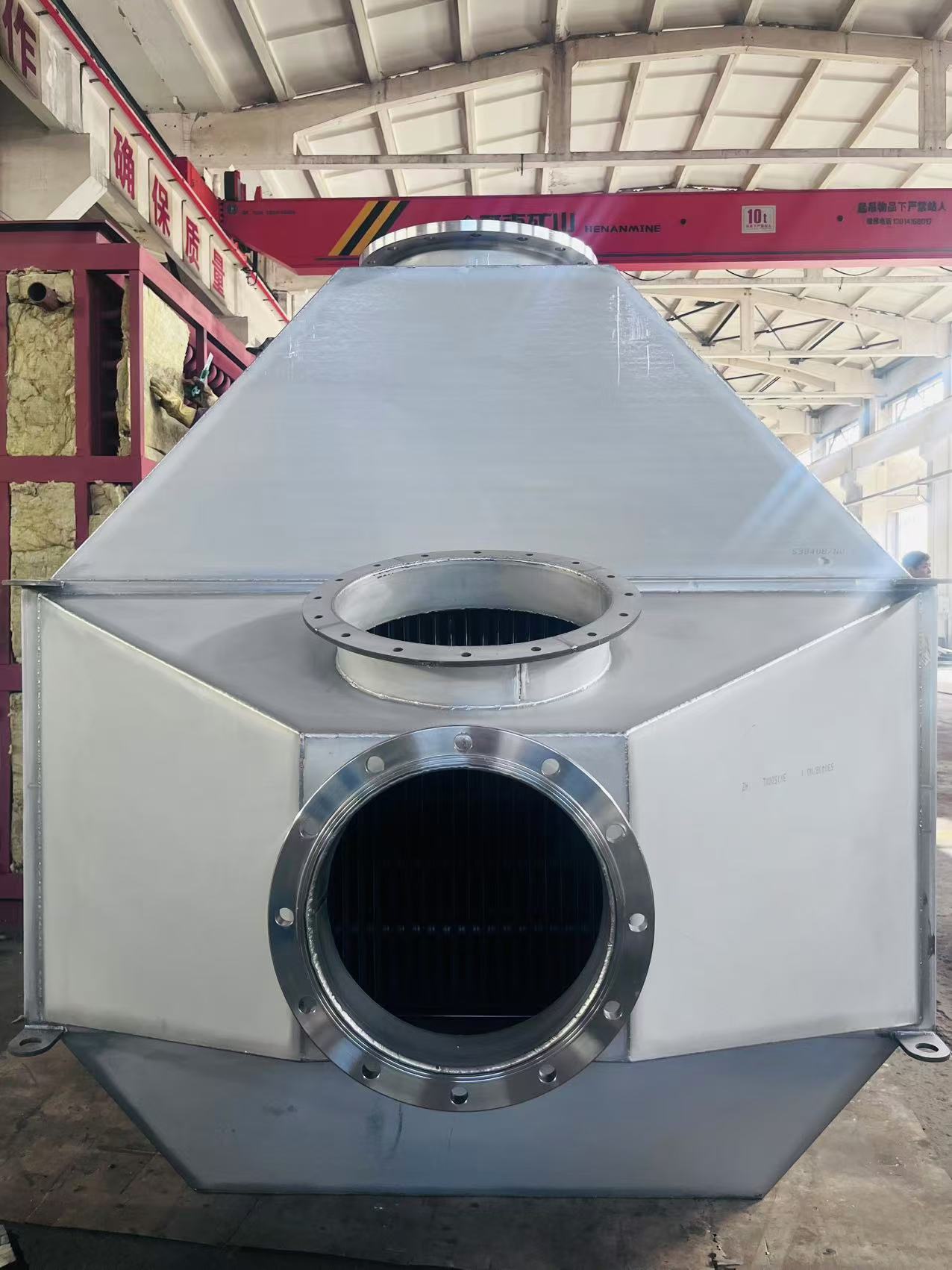

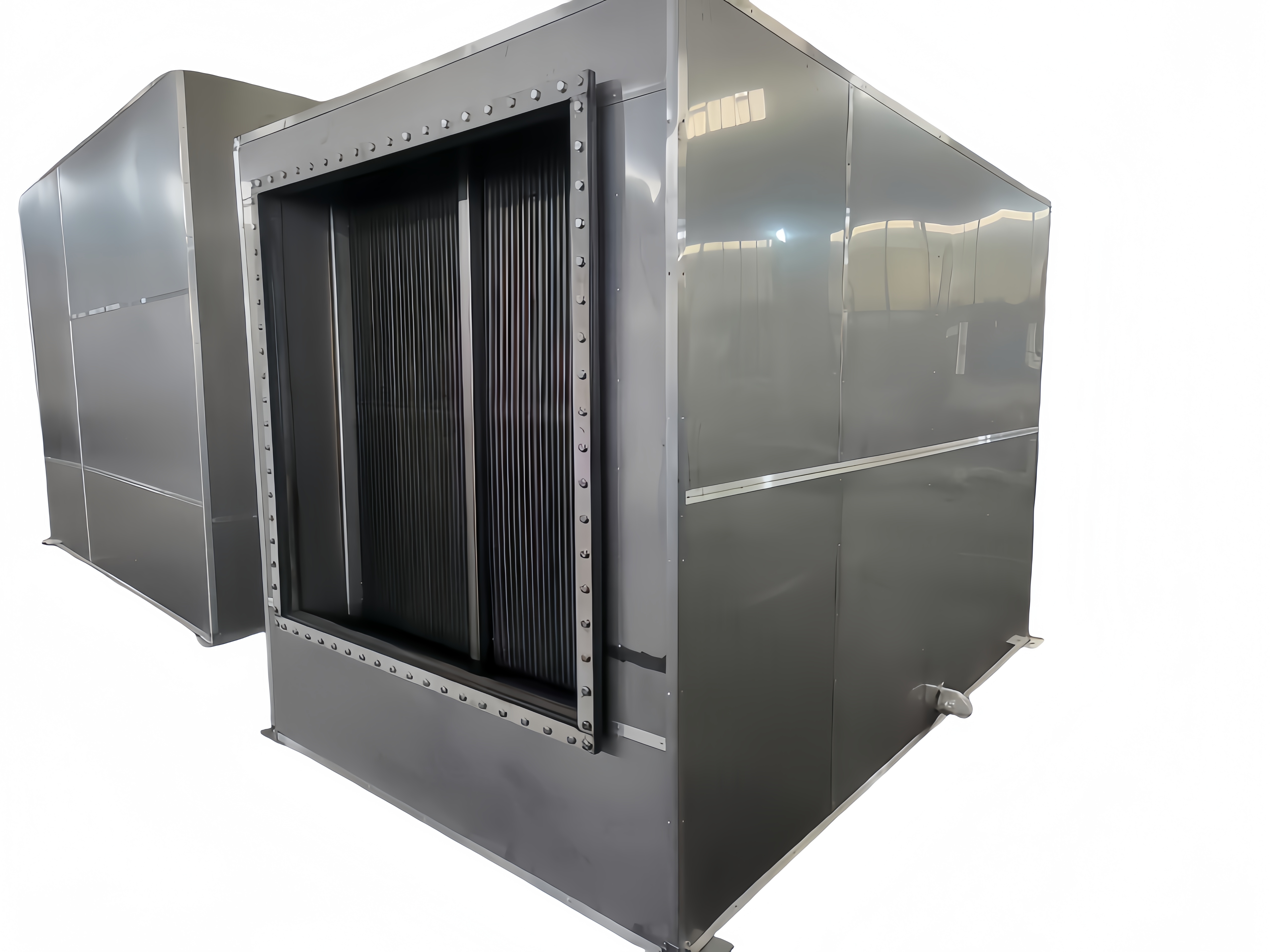

During industrial operations or the utilization of large-scale equipment like ship engines, sizable quantities of hot gases are released into the atmosphere as waste. Recuperative heat exchangers efficiently capture this thermal energy and transfer it to cooler mediums, such as water or air, without direct contact. This ensures seamless heat management and conservation, which is exceptionally beneficial in logistical hubs like ports.

This high-tech equipment handles temperatures up to 600°C, and in some cases, certain designs can tolerate even 1000°C. It transforms these captured heat streams into reusable energy, significantly enhancing the thermal efficiency of industrial processes and supporting technologies within logistics zones.

Key Advantages and Features

The advantages of using recuperative heat exchangers are multifold. One of the main benefits is energy saving. These devices can recapture up to 30–50% of heat that would otherwise be lost, translating to significant reductions in fuel consumption, whether it be natural gas, coal, or oil. Consequently, this contributes greatly to cost savings and sustainability—key priorities for modern industrial and logistical infrastructures.

Moreover, these systems promote eco-conscious practices by decreasing the carbon footprint associated with industrial operations. They aid in adhering to global environmental standards and transitioning toward a greener future for logistics networks. Built from corrosion-resistant materials like stainless steel, recuperative heat exchangers are designed to endure complex environmental conditions often encountered in port and coastal areas.

The Role in Port and Logistic Environments

Given the vast scale and continuous activity within ports, integrating recuperative heat exchangers offers unparalleled efficiency. Every step in the handling of thousands of containers daily requires cost-effective energy management, and this technology fits ideally into these challenging demands. From optimizing heating systems for storage facilities to supporting operational tasks, recuperative heat exchangers improve every corner of port logistics.

This innovative approach signals a shift toward more sustainable industry practices. The technology ensures maximum utilization of resources while boosting productivity, enabling ports and logistic hubs to achieve energy efficiency, reduce costs, and contribute to environmental preservation. With their durability and high-temperature resistance, recuperative heat exchangers stand out as an essential asset for modern industrial settings.