Introduction to Fin Tube Heat Exchanger

In the field of thermal management solutions, fin tube heat exchangers are the pinnacle of engineering creativity. As the industry grows, the need for efficient and reliable heat transfer systems has become crucial, making these switches an integral part of modern applications. They are built with a unique design that promotes optimal heat transfer, from chemical treatment to renewable energy systems. Let’s explore the complex features and wide application of fin tube heat exchangers, highlighting innovations brought by leading manufacturers such as Tenghao Machinery.

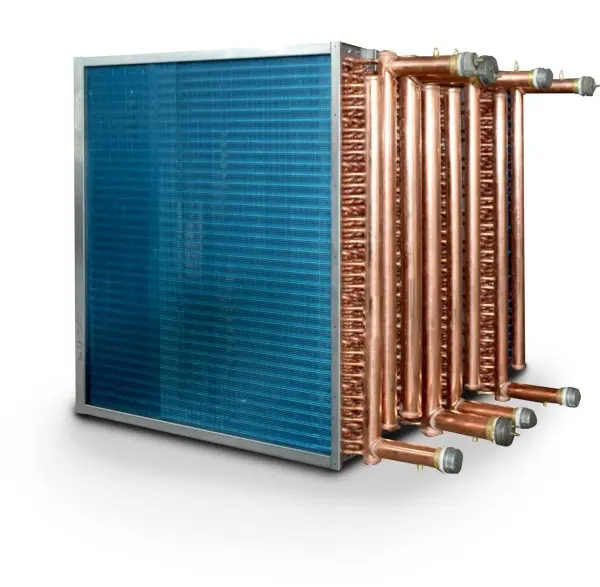

Revolutionary stainless steel aluminum fin heat exchanger

The innovation that reflects heat exchange technology is the stainless steel aluminum fin heat exchanger. This product is a groundbreaking tool that integrates durability with cutting-edge technology. The core of its efficiency lies in the strategic use of stainless steel and aluminum. Stainless steel has unparalleled corrosion resistance, ensuring long-term reliability even in challenging environments. Supplement this is aluminum fins designed for special thermal conductivity. This combination results in a powerful and lightweight unit that maximizes heat transfer performance.

Aluminum fins have smooth corrugated drawings that enhance surface area for upper heat exchange. This meticulous design not only improves energy efficiency, but also helps reduce operating costs, making the product environmentally friendly. In addition to functionality, the polished surface and clean lines of the exchange reflect high standards of quality and complexity, and the installation and function that are critical to aesthetic appeal.

Innovation behind Tenghao's fin tube air heat exchanger

Tenghao Machinery advances the advancement of heat exchanger technology by introducing fin-tube gas heat exchangers, which demonstrates precision engineering and aesthetic capabilities. The unit has intricate fins that optimize airflow and greatly improve heat transfer efficiency. These fins maximize surface area while focusing on details while maintaining a compact profile, ensuring unparalleled performance.

The equipment is made of advanced corrosion-resistant materials that ensure longevity and minimal maintenance in the most severe industrial environments. The integration of advanced welding and cutting technologies ensures consistent build quality, reducing wear and curbing operational downtime. Its powerful framework supports continuous use, thereby improving overall efficiency.

The unique blue color of the fin symbolizes advanced thermal conductivity, and echoes Tenghao's commitment to environmentally friendly products. This color choice emphasizes the exchanger's ability to effectively dissipate heat, save energy and minimize environmental impacts, seamlessly suits a wide range of industrial applications.

Strategic Assets for Operational Efficiency

Tenghao Machinery's Finned Tube Air Heiffanger is designed to meet strict industry standards, which reflects versatility. It is suitable for applications ranging from chemical processes to renewable energy, and it facilitates simple integration into existing systems, simplifying setup and enabling worry-free upgrades. Tenghao engineers use state-of-the-art design software to tailor these switches to specific customer needs, optimizing performance and reducing energy use and costs.

This product is certified by ISO9001:2015 and CE standards, exceeding the international quality benchmark and expressing a commitment to excellence and customer satisfaction. Whether it’s upgrading industrial processes, optimizing energy consumption or improving reliability, fin tube heat exchangers have strategic advantages in your operations.

Ultimately, a fin tube heat exchanger is more than just a device. This is a key asset in pursuing operational efficiency and environmental responsibility. It integrates advanced technology with practical everyday applications, aiming to meet today's challenges tomorrow.