The Growing Demand for Energy-Efficient Solutions

In today's rapidly evolving industrial landscape, companies are under increasing pressure to embrace technologies that are both efficient and eco-friendly. The term "energy-efficient heat exchanger" has become synonymous with the pursuit of sustainable operations without compromising performance. Traditional heat exchangers often fall short when it comes to balancing energy savings and thermal performance, leaving industries searching for more advanced solutions. Thankfully, modern innovations in heat exchanger designs aim to tackle these challenges head-on.

Heat exchangers are critical in numerous industries including HVAC systems, food processing, and renewable energy setups. Yet, many legacy systems are unable to meet the stringent efficiency demands of today’s world. Rising energy costs and the push for reduced carbon emissions have made upgrading to systems like high-efficiency heat exchangers more than an option—it’s now a necessity. These next-generation exchangers offer remarkable opportunities for energy savings and operational cost optimization.

Innovative Solutions for Thermal Performance

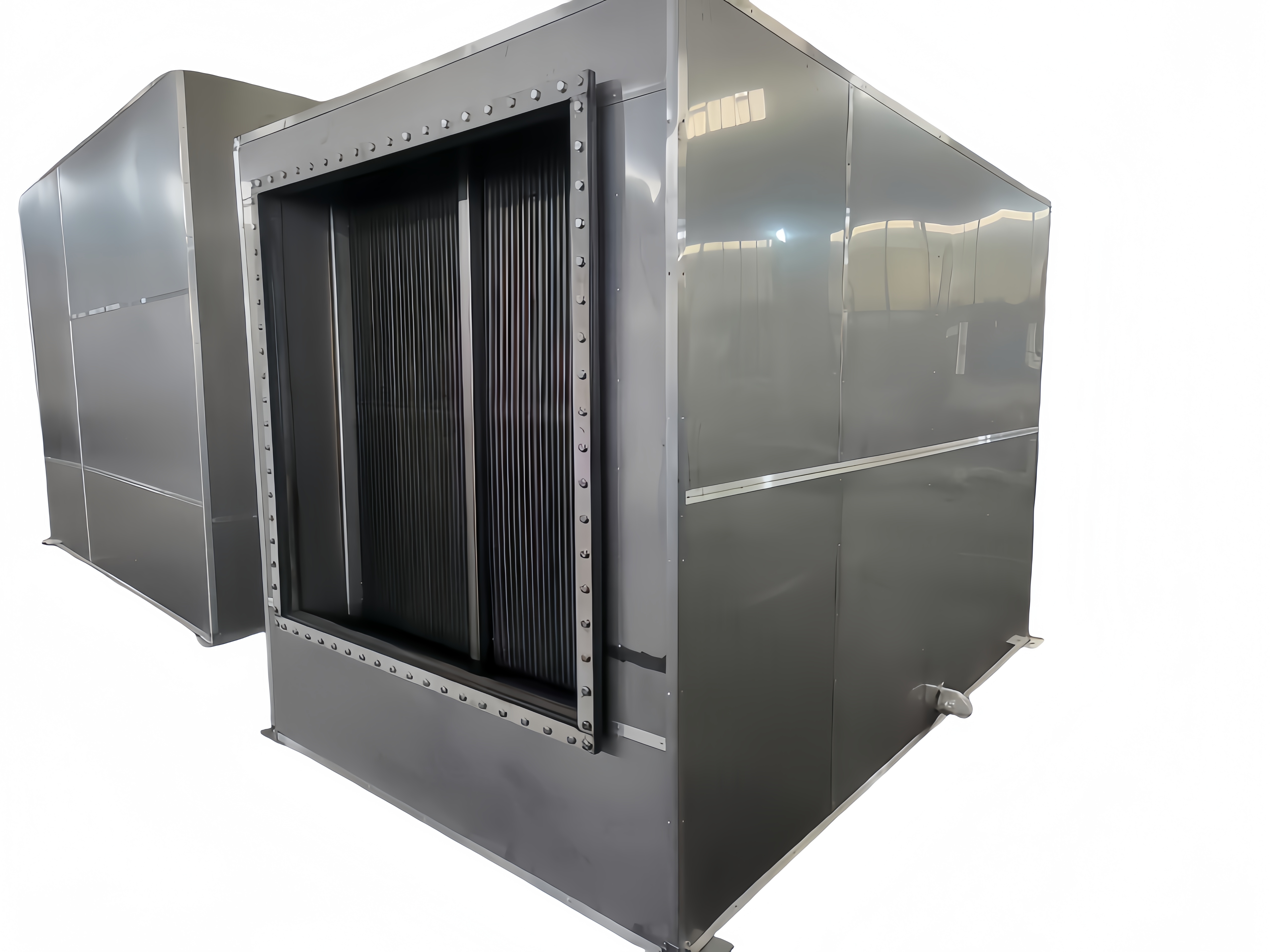

Modern energy-efficient heat exchangers, like the ones at the forefront of innovation today, deliver up to an impressive 95% heat transfer efficiency. Whether it's a compact plate heat exchanger or a robust tube heat exchanger, this new breed of technology is designed for optimal performance across industries. Plate heat exchanger efficiency, powered by microgroove surfaces and IoT-based capabilities, ensures effective thermal management on a smaller footprint. Compact heat exchanger solutions like these are ideal for industries where space and precision matter most.

One of the primary advantages of these systems is their ability to reduce energy consumption by 20-30% compared to older models. This isn’t just an achievement in energy savings—it’s a commitment to sustainability. Additionally, heat exchanger performance optimization tools empower operators to track and enhance efficiency metrics in real time. This dynamic capability ensures that operations run smoothly, even under the challenging conditions of high-pressure systems or diverse processing environments.

Redefining Sustainability and Cost-Efficiency

Eco-friendly heat exchangers stand at the crossroads of innovation and sustainability. By incorporating waste heat recovery technologies and eco-friendly materials, these exchangers provide a dual benefit of reducing energy costs and lowering carbon footprints. In a world striving to meet net-zero goals, this becomes a game-changer. Furthermore, the fine-tuned designs are tailored to ensure longevity, featuring anti-fouling coatings and high-quality materials that reduce maintenance woes.

What sets these industrial energy-efficient heat exchangers apart is their ability to deliver a substantial return on investment (ROI) within just 12-18 months of operation. In an era of rising operational costs, this is a financial and environmental win. From skyscrapers to processing plants, these modular and customizable heat exchangers showcase versatility by integrating seamlessly into any setup.

The Future of Heat Exchanger Technology

The continuous evolution in heat exchanger types and efficiencies highlights the industry's commitment toward solving energy challenges. With IoT-ready systems enabling real-time monitoring, businesses can now minimize downtime and enhance output. These innovations also allow for proactive adjustments in heat exchanger energy consumption, ensuring operations are as lean and effective as possible.

The craftsmanship and engineering precision in today’s best heat exchangers symbolize the relentless pursuit of excellence. Designed not merely for today but to meet the challenges of tomorrow, these systems represent the future of industrial thermal management. Whether in HVAC systems, power plants, or renewable energy installations, businesses can now embrace sustainable practices without compromise. The shift to energy-efficient heat exchangers isn’t just about reducing costs; it’s about aligning with a greener, more responsible future for the world.

Welcome to the era of smart, efficient, and eco-friendly heat transfer solutions. It's time to leave behind outdated, energy-draining systems and embrace a future that prioritizes both excellence and responsibility.