Boosting Energy Efficiency in the Petrochemical Industry

The petrochemical industry is highly energy-intensive, with processes like distillation, cracking, and reforming producing significant amounts of waste heat. Leveraging industrial heat recovery systems such as **Petrochemical Heat Recovery Systems** is an effective way to optimize operations, reduce carbon emissions, and achieve considerable energy savings. Waste heat utilization plays a pivotal role in transforming thermal energy into usable forms like electricity, steam, or process heat.

By capturing waste heat and repurposing it, chemical plants and refineries can not only cut operational costs by up to 40%, but also align with global sustainability standards. With solutions like plate heat exchangers and Organic Rankine Cycle (ORC) systems tailored specifically for high-temperature processes, heat recovery applications are at the forefront of petrochemical innovation.

Advanced Heat Exchange Technology for Maximum Benefits

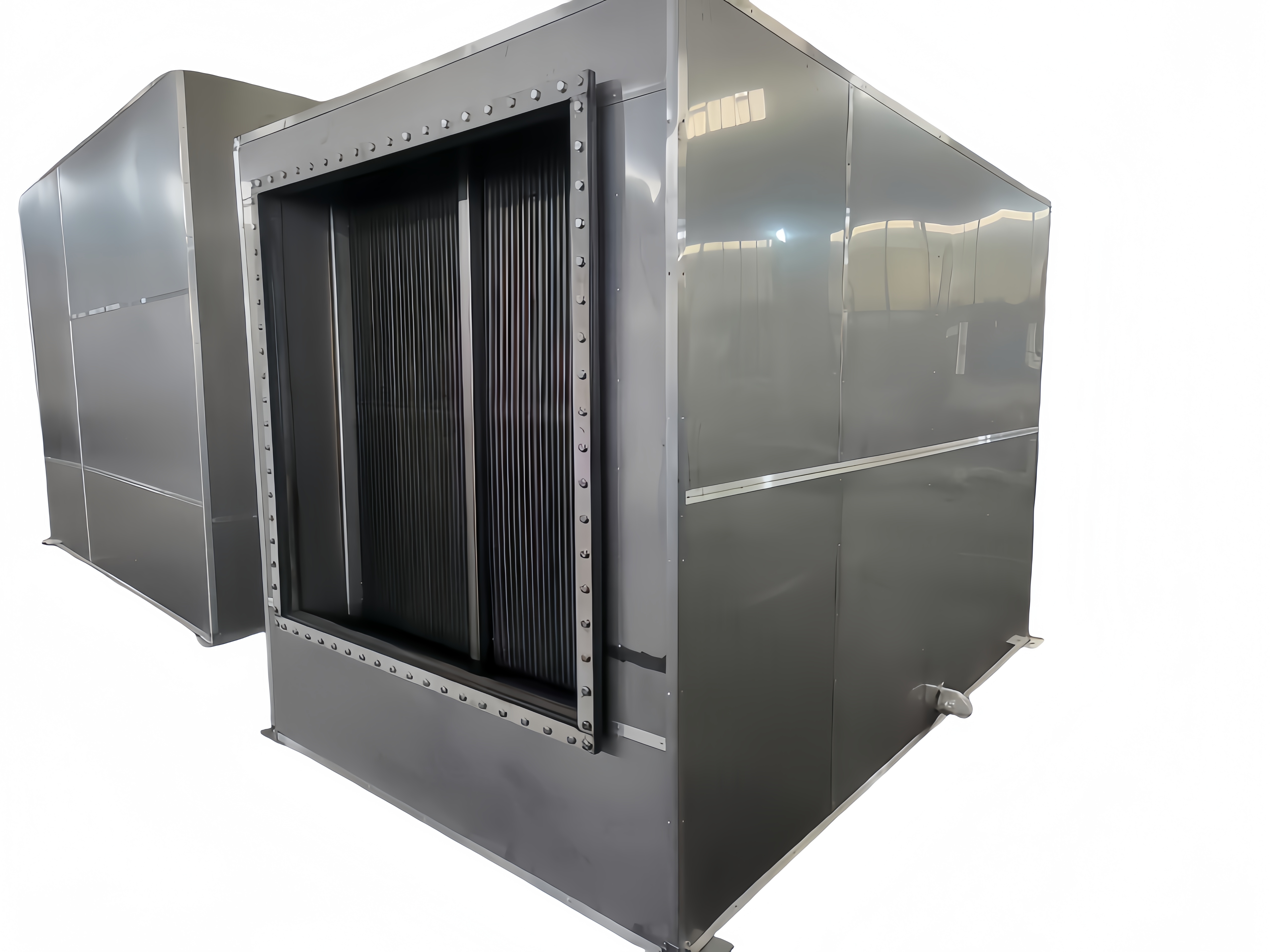

Designed to meet the unique challenges of petrochemical facilities, modern heat recovery systems incorporate cutting-edge features that define excellence in energy management. High-temperature capability ensures they can handle extreme thermal conditions, operating up to 600°C without compromising effectiveness. Revolutionary anti-fouling technology minimizes maintenance costs, while IoT-driven insights offer real-time monitoring and predictive analytics for seamless operations.

Premium-grade materials, from corrosion-resistant alloys to durable titanium, further enhance system durability in harsh industrial environments. Thanks to tailor-made configurations like shell-and-tube heat exchangers, plants have the flexibility to optimize feedstock preheating, steam production, and other critical processes. These technological advancements underscore the importance of efficient thermal energy recovery in petrochemical process optimization.

The Financial and Environmental Gains of Heat Recovery

Investing in waste heat recovery systems is not merely a step toward energy efficiency—it’s a cornerstone of long-term profitability and environmental stewardship. Refineries and chemical plants can achieve substantial energy cost savings, often ranging from 20% to 40%, translating to millions of dollars saved annually. Moreover, reusing thermal energy drastically lowers greenhouse gas emissions by up to 30%, helping operations comply with stringent environmental regulations.

The benefits extend to rapid ROI. Many petrochemical facilities report a return on investment within 12-24 months due to significant operational savings. Success stories include a leading refinery using ORC-based recovery systems to generate 5 MW of electricity, saving $2 million each year, and a chemical plant reducing fuel use by 25% through exhaust heat capture, cutting emissions by 18,000 tons annually. The versatility and impact of heat recovery applications make them indispensable for chemical plant energy savings.

Why Petrochemical Heat Recovery Systems Are the Future

As industries transition toward net-zero emissions, energy efficiency is no longer optional. Solutions like **Petrochemical Heat Recovery Systems** represent a fusion of technological innovation and sustainability, empowering the sector to thrive amidst mounting challenges. From meeting ESG benchmarks to navigating environmental compliance, these systems deliver unparalleled value for today’s competitive petrochemical operations.

[Your Company Name] is committed to driving this transformation, offering expert-designed systems, certified quality standards, and ongoing support to ensure client success. With a focus on profit enhancement, streamlined operations, and environmental responsibility, we stand as steadfast partners in unlocking the future of heat exchange technology.

The era of waste heat recovery in petrochemicals is here—redefining efficiency, profitability, and environmental stewardship for industries worldwide.