Revolutionizing Heat Exchange Technology

In the ever-evolving world of industrial operations, efficiency and sustainability stand as pivotal factors for ensuring long-term success. Our cutting-edge fin tube heat exchangers symbolize a major leap forward in heat exchange technology, specifically tailored for the oil and gas sector. These exchangers not only enhance thermal efficiency but also cater to a broad spectrum of industrial applications, setting a new benchmark for performance and resilience.

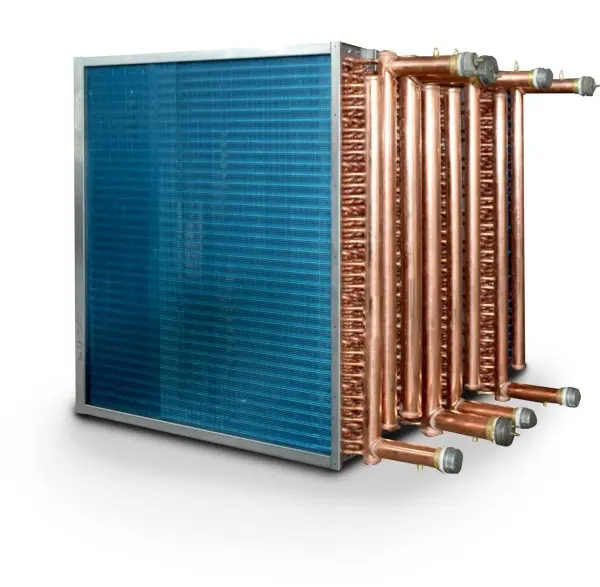

Advanced Design for Superior Performance

Our finned tube heat exchangers are a testament to innovative engineering. The sophisticated design incorporates thick-walled tubes paired with explosion-bonded fins, allowing these units to withstand pressures beyond 100 bar. The robust construction ensures they manage the formidable task of handling sulfur-rich gases, making them indispensable in challenging environments. What sets these exchangers apart is the use of premium materials such as Stainless Steel 316L, titanium, and Inconel, designed to combat extreme conditions including cryogenic temperatures and the corrosive nature of offshore saltwater exposure.

Efficiency during heat transfer is a highlight, with improvements of 30-50% through extended fin surface areas that are meticulously optimized using helical and studded geometries. This results in more effective heat transfer by promoting turbulent flow, a crucial factor in the operational enhancement of industrial heat exchangers. These design tweaks ensure our exchangers do more than just perform; they excel. With an impressive service life of 10-15 years, these heat transfer solutions represent durability and reliability, even amidst sour gas scenarios, while expertly handling two-phase flows without common issues like gasket or seal leaks encountered in alternative designs.

Pioneering Future Trends

Our commitment extends beyond immediate improvements; it ventures into trailblazing future trends. The modular aspect of our exchangers introduces ease of maintenance, bolstered by features such as automatic soot blowers which effectively prevent fouling. Furthermore, smart sensors integrated within the system allow for proactive monitoring, ensuring that the exchangers remain at peak performance over their lengthy operational lifespan. These advancements underscore a dynamic shift in the expectations surrounding industrial finned tube exchangers.

Moreover, the selection of materials is intelligently tailored to meet distinct temperature limits and specific conditions, reflecting a precise, application-centric approach. For instance, Titanium is ideally suited for sour gas processing while Inconel finds its niche in high-pressure hydrogen services. This strategic material selection exemplifies our mastery in finned tube manufacturing, providing flexibly engineered solutions that address the diverse challenges of the oil and gas industry.

In conclusion, our state-of-the-art fin tube heat exchangers redefine industrial efficiency by reducing operational costs and dramatically boosting process reliability. They are not just products; they represent a transformative journey in the realm of heat transfer solutions, delivering unparalleled performance and setting the stage for the future of the entire oil and gas value chain.