Revolutionizing Industrial Energy Recovery

In today’s fast-moving industrial era, the demand for energy efficiency and sustainability has never been higher. One of the most promising advancements in this domain comes in the form of waste heat recovery systems, which represent a pivotal step forward in thermal performance and energy management. At the forefront of this transformative technology is the Waste Heat Recovery Condenser from Wuxi Tenghao Machinery Manufacturing Co., Ltd. With a focus on condenser efficiency, this innovative product is redefining how industries utilize energy.

Unleashing the Potential of Waste Heat Recovery

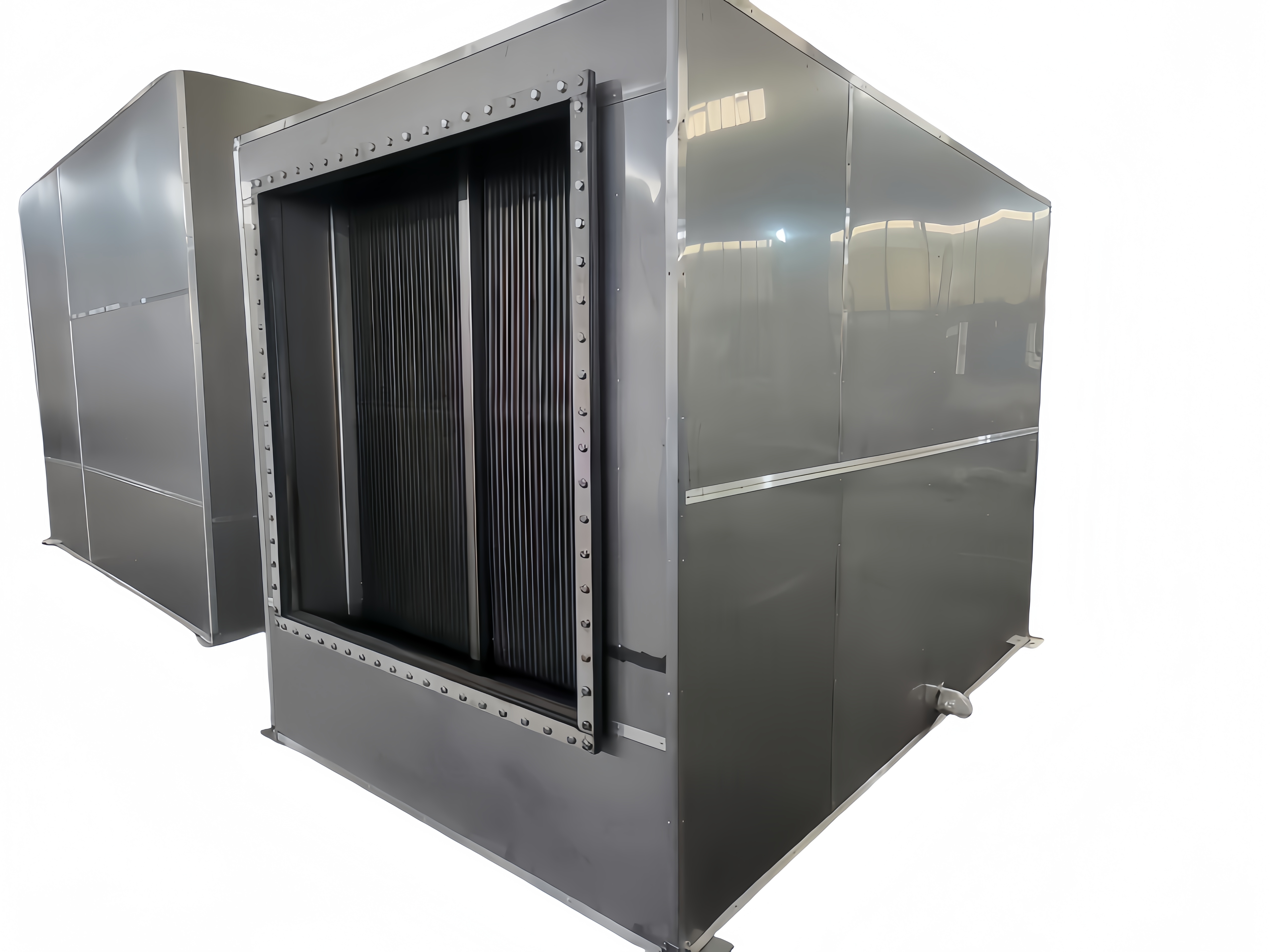

The Waste Heat Recovery Condenser is a masterpiece of engineering aimed at capturing and repurposing waste heat from industrial processes. This technology excels in extracting thermal energy from exhaust gases, steam, and process fluids, thus preventing valuable energy from being wasted. The resulting energy can be harnessed for heating, cooling, or even electricity generation, delivering energy savings of up to 30%. By achieving an impressive efficiency of up to 95%, this system maximizes the utilization of waste heat and ensures minimum environmental impact.

Built to Last with Robust Design

Durability and reliability are critical for industrial operations, and this condenser delivers on both fronts. Crafted from corrosion-resistant materials like stainless steel and titanium, it is designed to endure harsh industrial environments found in petrochemical plants, power stations, and manufacturing facilities. The inclusion of anti-fouling technologies minimizes maintenance requirements by 30%, offering an extended operational lifespan. Combine this with its compatibility across varying pressure and temperature ranges—up to 40 bar and 600°C respectively—and you have a product tailored to meet diverse industrial demands.

Compact and Smart Integration for Modern Facilities

While its capabilities are monumental, the Waste Heat Recovery Condenser is compact enough to integrate seamlessly into existing systems, saving precious factory floor space. Its IoT-enabled smart functionalities allow operators to monitor real-time analytics, optimize system adjustments, and schedule predictive maintenance, making it perfect for Industry 4.0 environments. The technology ensures efficiency tracking while providing insights to help industries fine-tune their processes for maximum thermal efficiency.

Driving Sustainability and Meeting Compliance

Industries implementing this condenser not only benefit financially but also take significant strides in environmental responsibility. By repurposing waste heat as a renewable energy source, carbon emissions can be cut by up to 30%. This aligns perfectly with ESG objectives and net-zero goals. Furthermore, the product complies with global safety and reliability standards, including ASME, CE, and ISO 9001 certifications, ensuring peace of mind for operators worldwide.

Real-World Benefits and Long-Term Value

The Waste Heat Recovery Condenser promises tangible benefits such as enhanced energy efficiency and thermal performance, allowing industries to achieve a return on investment within a short timeline of 12 to 24 months. Its Clean-in-Place (CIP) technology ensures hassle-free operation over a lifespan exceeding 15 years. Moreover, its adaptability to varying industrial requirements—from 50 kW to 10 MW in heat recovery capacity—renders it suitable for virtually any operation aiming for energy recovery.

Pioneering the Future with Smart Energy Solutions

As industry leaders continue searching for solutions to the challenges posed by climate change and rising energy costs, tools like the Waste Heat Recovery Condenser stand as beacons of hope. Whether deployed in petrochemical complexes or manufacturing hubs, its advanced features will undoubtedly pave the way for operational excellence and environmental sustainability. This is not just a step forward for industrial condensers—it is the next giant leap for waste heat utilization.

In redefining the way we approach waste heat recovery, Wuxi Tenghao Machinery Manufacturing Co., Ltd. has provided industries with a key to unlocking their energy potential, achieving unparalleled thermal efficiency, and moving towards a greener future.