Understanding Finned Tube Heat Exchangers

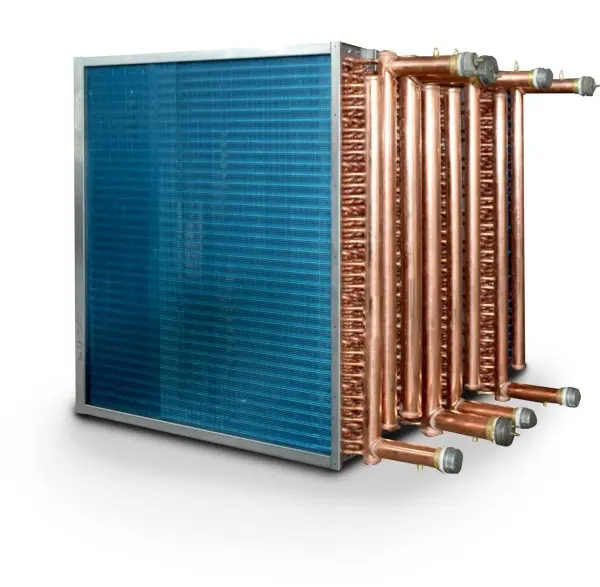

Finned tube heat exchangers are critical in various industries, offering efficient heat transfer solutions. These devices are especially vital in sectors such as oil and gas for both processing and thermal management. Their application includes oil and gas heat exchangers, where they facilitate the transfer of heat between different media. A significant evolution in this domain is finned tube technology, which has revolutionized heat exchanger design by optimizing surface contact for better heat transfer efficiency.

Applications and Benefits of Finned Tube Technology in Oil and Gas

Finned tube heat exchangers are integral to oil and gas thermal equipment. Their design allows for maximized heat transfer, making them indispensable in high-temperature and high-pressure environments. For instance, industrial finned tube exchangers serve as economizers in boilers, where they effectively resist high temperatures and ash corrosion. In the petrochemical industry, these heat exchangers are used as lightweight air coolers, efficiently managing heat loads with aluminum fins and carbon steel tubes. Moreover, finned tube applications in the oil industry include air preheaters, economizers, and exhaust recovery systems, all crucial for maintaining operational efficiency.

Choosing the Right Finned Tube Heat Exchanger

When selecting a finned tube heat exchanger design, consider the specific requirements of your application. Welded finned tube heat exchangers provide robust joint strength and withstand vibrations, making them suitable for boilers and petrochemical environments. Mechanical expansion joining method offers efficiency for low-pressure conditions and cost savings. The material choices for finned tubes are also critical; for example, carbon steel is economical for non-corrosive media, while stainless steel suits acidic or marine environments. Copper configurations cater to HVAC and refrigeration demands, offering high thermal conductivity. Given their broad spectrum of application, including oil and gas processing equipment, choosing the right finned tube is crucial for optimizing performance and durability across various thermal management needs.

The Latest Innovation: Spiral Wound Finned Tube

The newest advancement in finned tube technology is the Spiral Wound Finned Tube. This product is engineered to optimize heat transfer efficiency and durability across various industrial applications. It features a fins-per-inch (FPI) range of 3 to 12, catering to applications demanding high-density fins like air coolers. The fin height, ranging from 5mm to 20mm, is designed to handle both moderate and high heat loads, ensuring superior thermal performance. High-Frequency Welding and Mechanical Expansion methods enhance joint strength and optimize cost-efficiency depending on the application. With temperature endurance up to 600°C and pressure resistance up to 15 MPa, these finned tubes suit high-temperature exhaust recovery and HVAC systems. Ensuring international certifications like ASME BPVC and ISO 9001, the Spiral Wound Finned Tube stands as a testament to advanced thermal solutions in demanding industries.

In conclusion, finned tube heat exchangers are indispensable in various high-temperature applications, particularly in the oil and gas industry. Their advanced design and material adaptability ensure optimal performance and durability, making them a crucial component in efficient thermal management solutions.