What is a fin tube radiator?

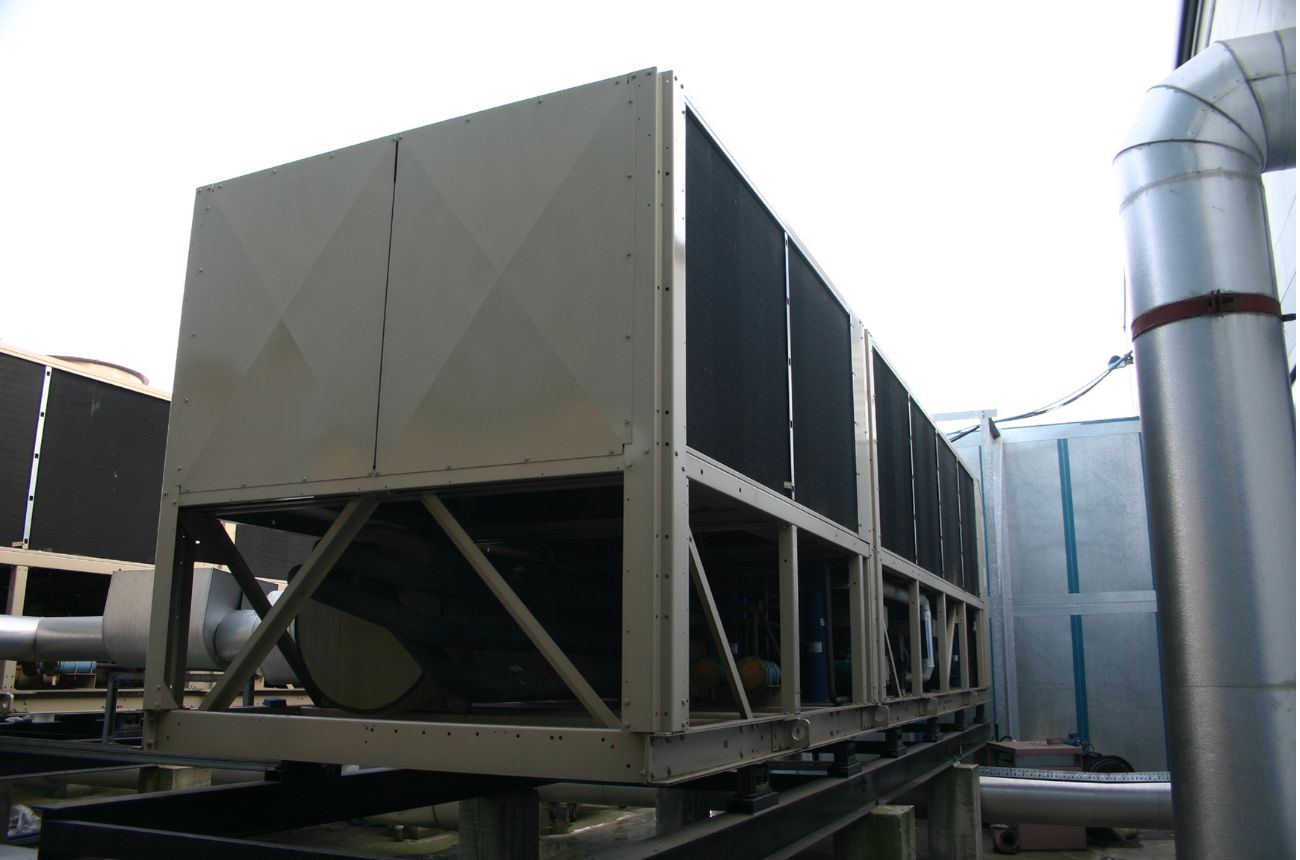

Fin tube radiator is an essential component in modern heating systems and is widely recognized for its effective heat transfer capability. These systems use fin tubes equipped with extended surfaces to maximize heat transfer between the culture media. Whether for residential, commercial or industrial applications, fin tube radiators provide a compact and effective solution to manage heating needs. They are particularly beneficial in space-aware settings where effective energy management is crucial.

Understanding Fin Radiator Design

The fin radiator design is a marvel of engineering that ensures optimal thermal efficiency. The fins on the tube expand the surface area for heat exchange, allowing it to dissipate or absorb energy faster than conventional systems. By leveraging this design, these radiators achieve higher heat transfer coefficients, allowing for faster and more efficient temperature regulation. Innovative products such as flat panel heat exchangers integrate such designs to enhance performance, providing a modular arrangement and compact structure. This makes them ideal for facilities with space constraints while maintaining top-notch efficiency.

Application of cross-industry fin tube radiator

The application of fin tube radiators spans a variety of industries. In HVAC systems, they provide effective heating and cooling solutions for residential and commercial buildings to ensure comfort and energy saving. Chemical processing facilities rely on them for precise temperature control during reactors and distillation. In the food and beverage industry, these radiators assist in pasteurization, cooling dairy products and ensuring aversion to safety. They play a key role in power generation by cooling lubricants and assisting with the thermal recovery process, thereby improving overall efficiency. Their versatility makes them essential in industrial and commercial settings.

The benefits of fin tube radiator

The benefits of fin tube radiators are numerous. First, they provide enhanced thermal efficiency thanks to their unique design. Their compact size saves space, making them ideal for installations of limited square feet. Additionally, they are made of durable materials such as stainless steel and titanium, ensuring resistance to corrosion and oxidation in harsh environments. Their modular configuration provides adaptability for different applications, with customizable features such as simplified maintenance and replacement of the washer model for the board. Furthermore, by minimizing energy consumption and scaling, they reduce operating costs over the long term.

Installation and efficiency of fin tube radiator

The installation of the fin tube radiator is simple, but accuracy is the key to maximizing its performance. Proper installation ensures that the radiator operates at peak efficiency, allowing for minimal energy waste. Products like plate heat exchangers can reflect this efficiency and customizable heat transfer areas and flow rates are tailored to a variety of industrial needs. Their design ensures dirt reduction, seamless integration with existing systems, and compliance with international standards, ensuring reliability and safety.

How to innovate industrial heating systems for fin tube radiators

Industrial fin tube radiators, such as those of power generation, oil refining and large-scale HVAC systems, are changing the landscape of thermal management. Their ability to handle extreme temperatures and pressures while maintaining durability and efficiency makes them a game-changer in demanding industrial applications. The board heat exchanger has a modular design with advanced thermal efficiency and adaptability, reflecting the benefits of fin tube technology to provide energy and cost efficiency in a robust packaging.

Fin tube radiators are the future of effective heat transfer systems. Their innovative design, various applications, cost-saving benefits, and ease of installation make them an excellent investment for industrial and commercial purposes. As the industry continues to prioritize sustainability and energy efficiency, adopting advanced solutions such as Finned Tube radiators will undoubtedly impact next-generation thermal management.