Maximize energy efficiency through gas to gas waste recycling unit

In today's industrial landscape, achieving sustainability without compromising productivity is a major challenge. This is where advanced waste heat recovery systems come into play. Utilizing waste heat is not only a technological innovation; it is a critical step towards building an environmentally responsible industry. With solutions such as natural gas waste recovery units, businesses can leverage waste heat recovery technology to achieve significant thermal efficiency, up to 85% in many cases.

Explore sustainable solutions in industrial thermal recovery

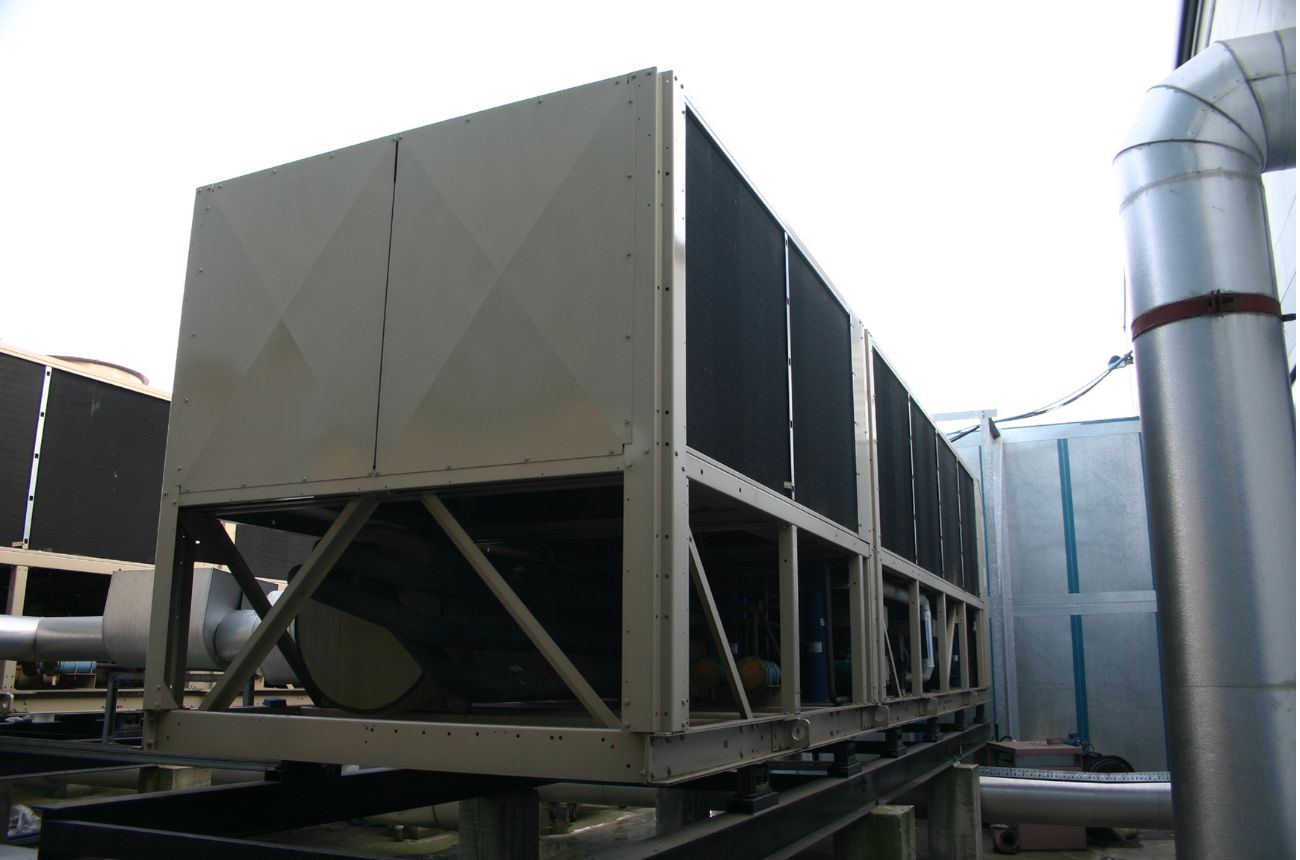

The waste heat recovery system redefines energy optimization by leveraging the heat emitted during industrial operations. Our cutting-edge systems are carefully designed to transform facilities into a sustainable power chamber. These systems have options such as plates, shells and heat pipe heat exchangers that effectively handle temperatures from 200°C to an incredible 1000°C, ensuring robust performance in a variety of industrial environments. This revolutionary approach will increase energy efficiency, reduce fuel costs and significant environmental impacts, which makes our gas-to-gas waste recovery unit the cornerstone of modern energy efficiency solutions.

For steel mills, preheating combustion air can cut fuel expenses by 25%. Chemical plants can generate steam through the reactor cooling process, saving up to $500,000 a year. Similarly, in glass production, the system utilizes a melting furnace exhaust to discharge the paint to an impressive 15%. These applications emphasize the transformative power of industrial heat recovery and demonstrate why waste heat is an integral part of sustainable industrial ecology.

Improving thermal efficiency and sustainability

Our waste heat recovery technology represents not only energy-saving systems, but also our commitment to global environmental goals. By adopting modular systems that fit seamlessly into existing infrastructure, we offer solutions that fit together with the required ESG benchmarks. In addition, the IOT-based monitoring dashboard allows the industry to track its carbon footprint in real time, demonstrating transparency while increasing operational efficiency.

The environmental impact does not stop there. Facilities equipped with waste heat units can redefine benchmarks to reduce CO2 emissions per megawatt-hour of recovery heat. This combination of technical capabilities and sustainability makes our products the future of thermal energy recovery. Coupled with self-cleaning anti-pollution design and strong maintenance support, the industry ensures maximum run time without additional workload.

Innovative solutions for industrial needs tomorrow

As the industry develops, the demand for smarter and more resilient energy solutions continues to grow. We are innovating endlessly, integrating AI-driven thermal optimizations and exploring hydrogen-compatible material upgrades for clean energy processes. Our gas exhaust gas recovery systems are equipped with features such as IOT enabled performance analysis, reflecting the pinnacle of sustainable industrial innovation. These advances are expected to continue to make breakthroughs in efficiency and underline our commitment to strengthening the industry through energy efficiency solutions.

Convert your facilities with waste heat recovery system

Imagine the miracle of turning your plants into energy-saving. Our natural gas waste recovery units offer unparalleled ROI potential and environmental benefits that can redefine your operating landscape. Whether you are considering upgrading a steel plant, chemical plant, glass production location, or any other high-energy facility, our systems are the ultimate solution for industrial optimization.

Explore case studies, review our manual or request a custom ROI analysis today. Join us to set new benchmarks for sustainability, operational efficiency and energy conservation. Together we can revive your plant’s energy journey, create cost savings, and contribute meaningfully to a greener future.