Understand the heat recovery unit of natural gas waste

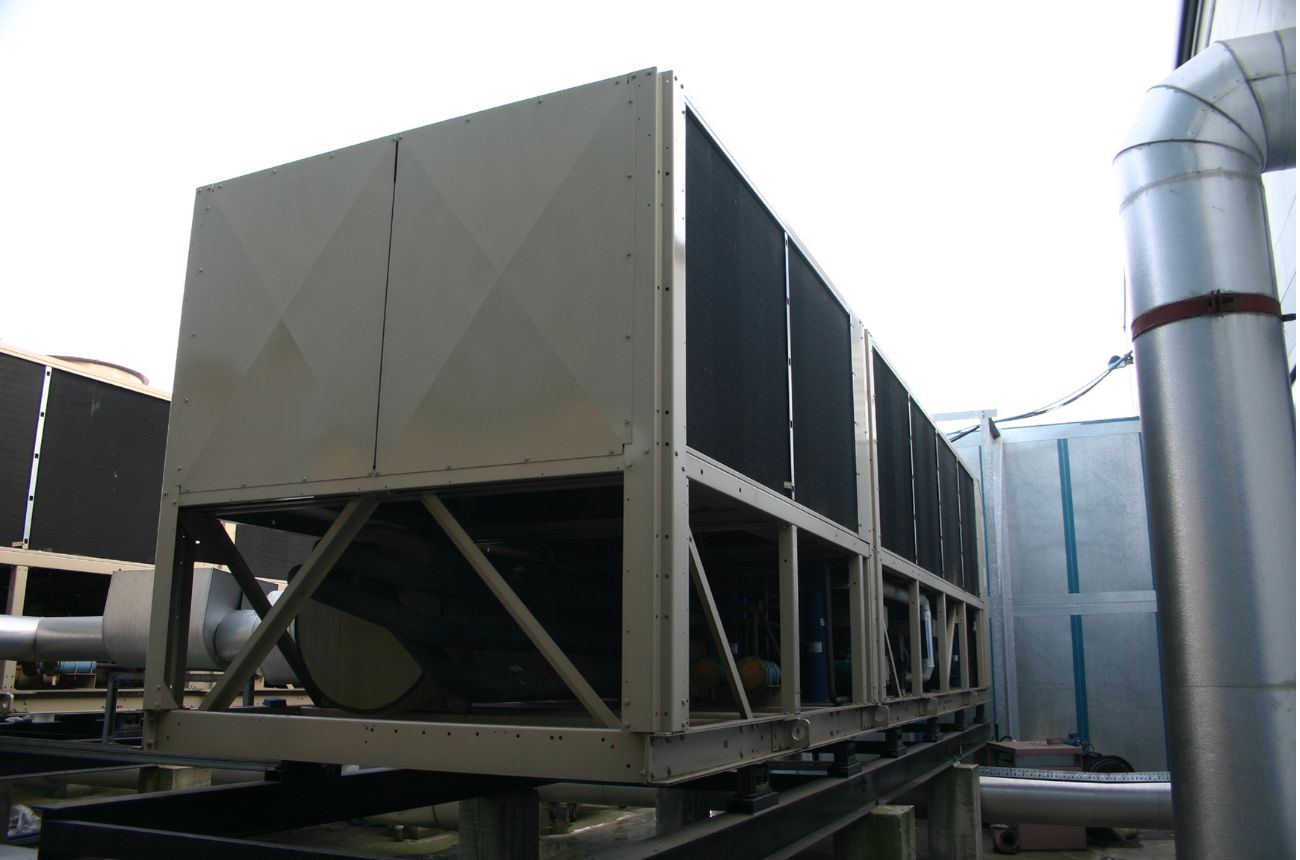

Gas-to-gas waste recovery unit (WHRU) is critical in improving energy efficiency in industrial processes. By using waste heat recovery technology, these systems would otherwise recover lost heat energy, which not only reduces energy costs but also minimizes carbon emissions, thereby promoting the sustainability of industrial operations. With innovation reaching thermal efficiency of up to 85%, it is clear that these units are reshaping the way industries use energy.

Key features and benefits of precisely designed stainless steel steam air exchange

Our latest product is precisely designed stainless steel steam air switches that are revolutionizing the industrial thermal recovery field. These exchangers are designed with advanced materials such as 316L stainless steel to resist corrosion and maintain high thermal conductivity, ensuring longer life and optimal performance under extreme conditions. The incorporation of copper tubes can increase heat transfer rates, simplify the process and reduce downtime.

These switches are specially designed to improve energy efficiency in various industries, including customized design systems for individual industry needs. Whether you are using medicines, food and beverages, or energy production, these switches are 15-20% more efficient than traditional models. In addition, these units are equipped with sensors with IOT, providing predictive diagnostics and real-time monitoring capabilities, ensuring uninterrupted operation and reduced maintenance costs.

Enhanced waste heat recovery with advanced IoT capabilities

The integration of IoT in our exchanges marks a new milestone in industrial thermal recovery solutions. Real-time performance monitoring and predictive diagnosis enable plant managers to optimize energy use and keep operations seamless. This ultimately leads to a sharp decline in the carbon footprint of lower energy consumption, reduced operating costs, and industrial facilities.

In addition, the design philosophy behind these switches focuses on sustainability. By leveraging proprietary board configurations and reducing energy use by up to 40%, they contribute to cleaner, more efficient industrial processes. They are ideal for a variety of applications, including USDA-approved setups for food grade heating or hydrogen preparation systems for chemical plants. These heat exchangers not only support the heat utilization of waste, but also increase the standards of global industrial thermal recovery systems.

Applications and Advantages in Industrial Field

Precisely designed stainless steel steam air switches have shown their efficiency in multiple departments. In the pharmaceutical industry, sanitary design and clean steam functions ensure compliance with strict hygiene standards. For food and beverage applications, these switches promote high-scale heat treatment while complying with USDA requirements. Energy and chemical sectors benefit greatly from their durability and suitability, such as handling HCL vapor or elevated pressure conditions.

In addition, their sustainable design reduces life cycle costs and operating expenses while ensuring environmental compliance, a dual benefit of ROI and corporate responsibility. With automated board stacking robotics and hydrogen preparation thermal systems capabilities, these switches will be suitable for the future and adapt to emerging industrial challenges.

The next step towards sustainable efficiency

Embraising energy efficiency solutions such as natural gas waste recovery units is indispensable to creating a sustainable industrial future. Please contact us to schedule a free thermal efficiency review or explore our IoT Beta testing program to experience the state-of-the-art features of these communicators firsthand. Let us help you redefine the industrial thermal recovery process while achieving environmental and operational excellence.