What is a fin tube radiator?

Fin tube radiators are specialized heat transfer devices designed to improve energy efficiency through enhanced surface area use. They use fins attached to the tubes to promote faster heat exchange by increasing the contact area of ambient air or liquid. It is crucial to understand the operating principles behind fin tube radiators, especially for industries that require precise thermal management solutions. The use of radiators has grown considerably due to their adaptability and effectiveness in various environments.

Application of Fin Tube Radiator

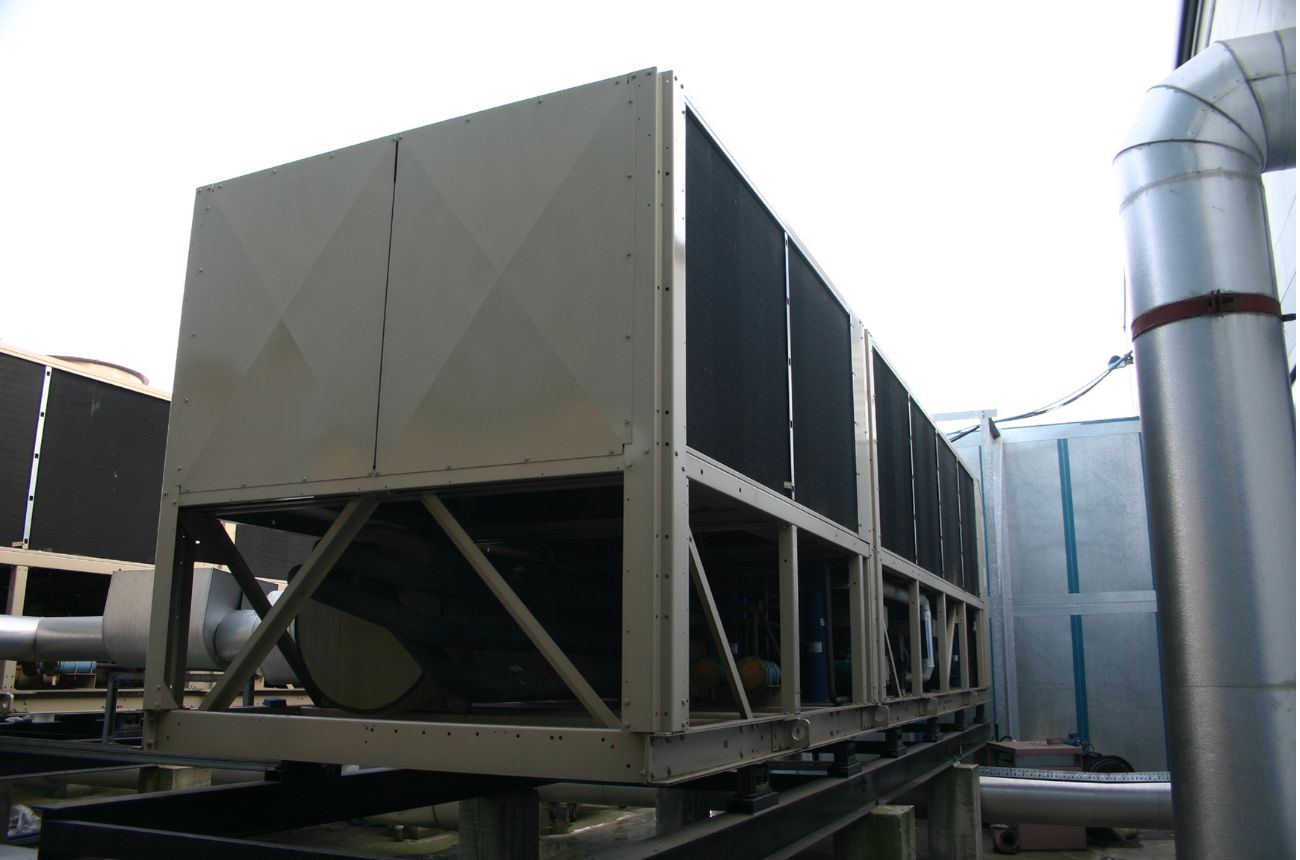

Fin tube radiators have found applications in a wide variety of industries. For example, power plants use them for heat recovery steam generators to maximize energy efficiency and reduce environmental impacts. The HVAC system relies on radiator design for optimized performance in condensers and evaporators, making indoor climate control more efficient. In addition, chemical processing plants use fin tube heat exchangers in reactors, which contribute to operational accuracy and durability. Industrial fin tube radiators also play a crucial role in oil and gas facilities, renewable energy systems and large-scale manufacturing lines.

The benefits of fin tube radiator

The benefits of fin tube radiators are numerous. First, their corrosion-resistant pipes also ensure long-term function even under harsh conditions. Customizable heat sink designs such as G-FIN, extrusion and welding variations can be flexibly met with specific heat exchange requirements. After correct installation, the fin tube heating system also improves efficiency, which translates into a reduction in operating costs for the enterprise. Industrial fin tube radiators stand out in terms of high performance and energy saving capabilities, becoming the first choice for smarter and cleaner technologies in modern enterprises.

Fin tube radiator installation and maintenance

Installing a fin tube radiator requires careful planning and accuracy. It is crucial to consider the environment, expected application and heat transfer requirements to ensure optimal performance. Working with manufacturers such as [Company Name] specializing in fin tube technology ensures first-class quality control and short lead times. Since AI-driven quality control systems are integrated into these designs, maintenance is also simple. Regular cleaning of fins and tubes ensures efficiency and extends the life of the radiator.

Why choose [Company Name] as the fin tube solution?

[Company Name] utilizes state-of-the-art manufacturing technology to provide high-quality fin radiators tailored to industry-specific needs. Their focus on innovation includes corrosion-resistant materials, customizable designs, and IoT smart heat exchangers for intelligent monitoring. With short lead times, businesses can quickly integrate these radiators into their operations without compromising quality. Their commitment to sustainability and energy efficiency positions [company name] is a leader in industrial heat transfer solutions.

For those exploring reliable and efficient fin tube radiators, [Company Name] offers unparalleled expertise and innovative options to meet the most demanding requirements. Contact their team today for personalized inquiries and take major steps to improve your heat transfer system.