Understanding the importance of board heat exchangers

Plate heat exchangers play an important role in industries where effective heat transfer solutions are needed. These innovative systems, commonly known as compact heat exchangers or washers heat exchangers, are designed to provide unparalleled energy efficiency and reliability. Industrial board heat exchangers are designed to involve complex engineering concepts to ensure excellent performance in a variety of applications such as HVAC systems, power generation and refrigeration.

A important advantage of board heat exchangers is their compact design. Unlike traditional bulky alternatives, these systems maximize heat transfer efficiency while saving valuable space. Whether you need heat exchangers for residential HVAC systems or high demand industrial processes, board heat exchangers offer customized solutions to meet all requirements.

Evolution of Heat Transfer Equipment

The development of heat transfer equipment provides advanced options for the industry, such as welding plate heat exchangers. These devices are very robust and are designed to handle high pressure and high temperature environments. When used in combination with high-quality materials such as copper or stainless steel, their durability and corrosion resistance make them ideal for demanding conditions.

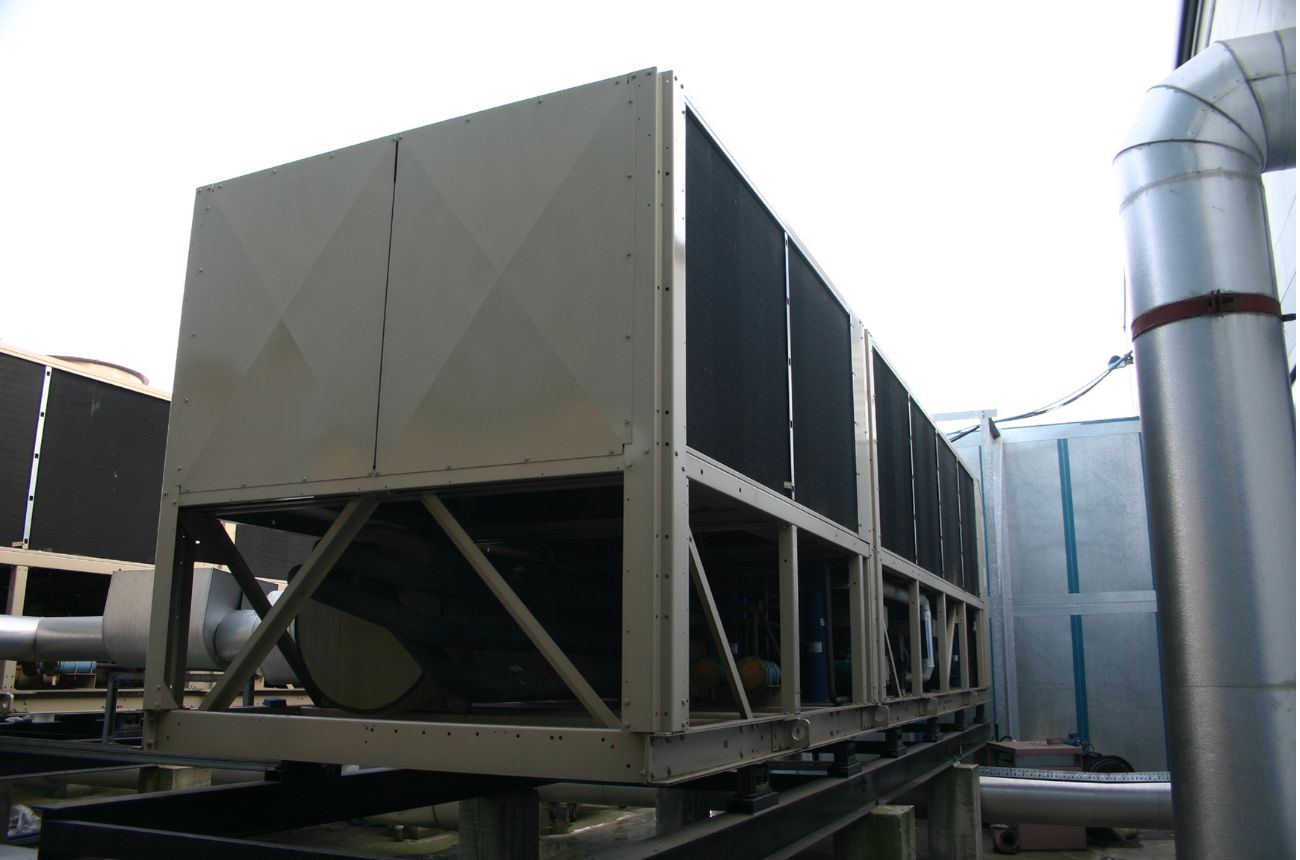

A outstanding example in this field is a fin tube heat exchanger. This cutting-edge product represents its peak thermal management, thereby enhancing the surface area and external fins are being designed to promote excellent thermal conductivity. These systems are not only energy-efficient, but are low-maintenance, making them the first choice among manufacturers of plate heat exchangers.

Fin tube design minimizes energy waste while providing rapid absorption or dissipation, ensuring industries such as automotive, aerospace and renewable energy benefit from reliable, cost-saving technologies. In addition, its customizable features allow the industry to choose from a variety of fin geometries and pipe compositions to perfectly suit its unique application.

Customization - the key to operational excellence

Customization has become the cornerstone of modern heat exchanger design. Whether you are aligning with industrial board heat exchangers or exploring compact heat exchanger solutions, the ability to modify the design ensures optimal application efficiency. Options include washers or welding configurations, various material options, and different fin designs such as L, LL, KL and G models as shown in the copper fin tube heat exchanger.

The industry attaches importance to the adaptability of these functions. For example, in the oil and gas industry, precise heat exchanger design promotes the management of extreme fluid temperatures. Similarly, in the HVAC industry, these switches maintain ideal climate control while consuming minimal energy. Even in renewable energy projects, heat exchangers play a crucial role in systems such as solar panels or geothermal heating units.

The Future of Board Heat Exchangers

The future of heat transfer solutions depends on innovations that enhance energy conservation, operational life and environmental sustainability. Plate heat exchangers, including advanced models such as fin tube heat exchangers, are leading charges by providing industry-specific solutions that combine all of these benefits. Their stylish, versatile design reflects how far the heat transfer equipment has gone, providing industries around the world with support to achieve their efficiency goals.

Selecting the right heat exchanger requires understanding of the specific needs of the system. With options ranging from compact heat exchangers to high-performance industrial models, modern manufacturers make it possible to find the perfect thermal management solution. As the industry continues to prioritize performance and sustainability, board heat exchangers are expected to remain an integral asset for the next few years.