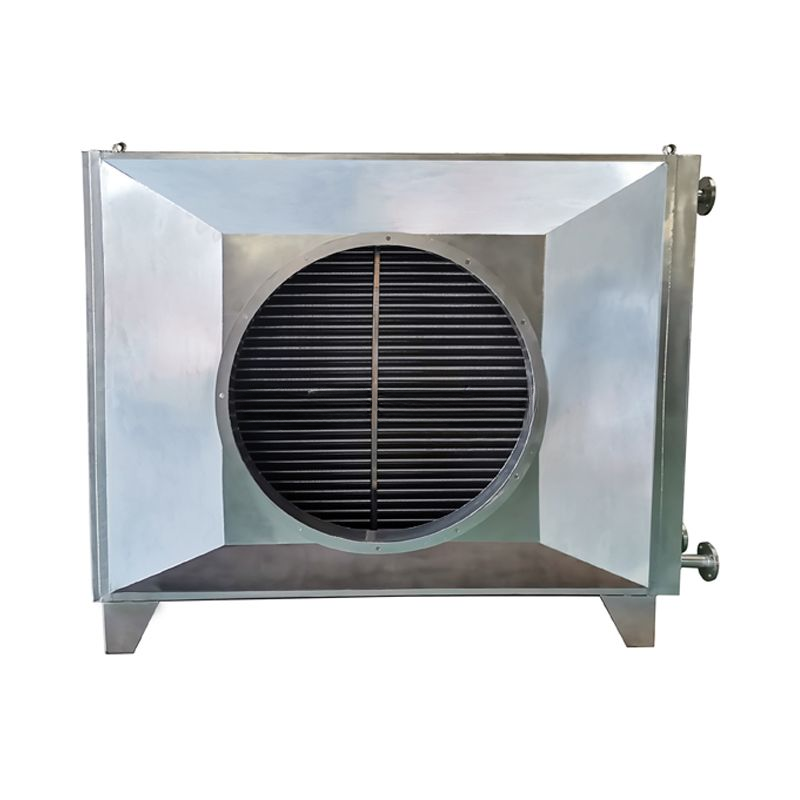

Introducing heavy industrial heat exchangers

In the field of industrial thermal management, equipment that is both efficient and flexible can make significant differences. Heavy duty industrial heat exchangers prove this principle. This powerful machine is designed specifically for tough environments and typically reflects efficiency and durability. Its design combines carefully crafted structures that utilize advanced materials to improve thermal conductivity and extend the service life of the equipment. At the heart of its design is a fin tube heat exchanger, a technologically advanced solution that maximizes heat transfer efficiency.

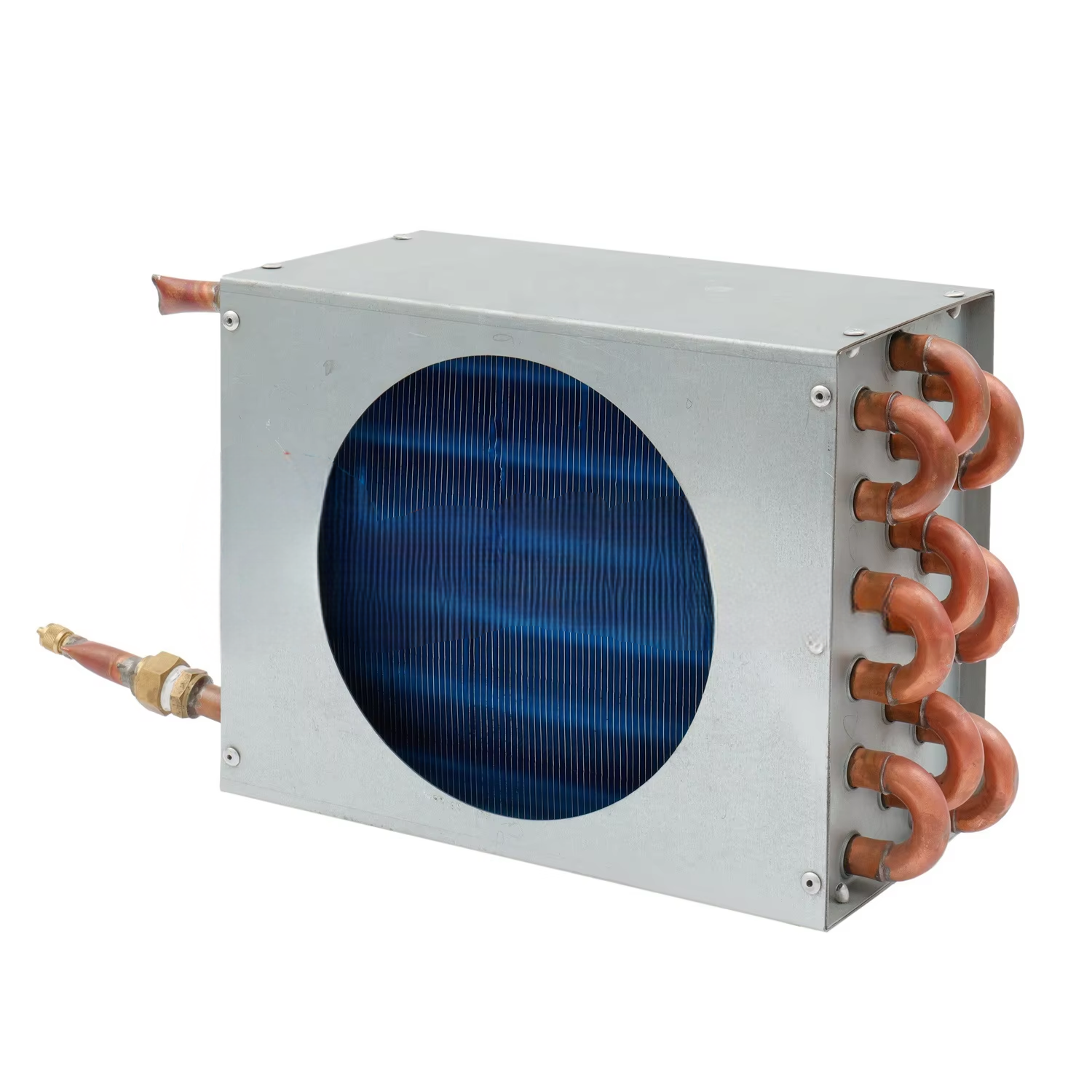

The unparalleled efficiency of fin tube heat exchangers

The reason for setting this heat exchanger is that its tightly packed array of tubes ensures a high level of heat transfer efficiency. This configuration not only improves cooling performance but also greatly reduces energy losses, which is ideal for industries aimed at optimizing energy use and reducing operating costs. Through the integration of fin tube heat exchangers, these units enable excellent thermal performance with minimal energy input. Fin tubes increase surface area for heat exchange, ensuring high efficiency even under the most demanding conditions.

Stylish design and easy maintenance

In addition to its functional capabilities, this industrial heat exchanger also has a smooth green finish. Not only is this an aesthetic enhancement, it also provides practical benefits such as corrosion resistance, ensuring that the machine maintains its elite level of performance under various operating conditions. Corrosion resistance is critical in high temperature processing facilities and required cooling systems, in which case exposure to severe elements is common. Ensure that these switches maintain their function without succumbing to ambient pressure sources, this feature greatly extends the available life of the machine.

In addition, through easy maintenance access and user-friendly installation design, businesses can reduce downtime. A simplified maintenance procedure means less time is spent on maintenance and more on operational productivity. This user-centric design not only helps seamlessly integrate into existing systems, but also ensures that routine repairs and inspections do not disrupt daily operations.

Why choose a heavy duty industrial heat exchanger?

Selecting the right heat exchanger is essential to maintain the efficiency of the industrial process. This particular model embodies the spirit of innovation and engineering excellence. It is not only a product, but a complete thermal solution tailored to those seeking reliability and efficiency in operations. Whether your needs involve high temperature treatment or strict cooling requirements, this heat exchanger offers a powerful solution.

Given its design efficiency, integration of fin tube heat exchangers, and many advanced features, heavy duty industrial heat exchangers are particularly suitable for industry professionals who prioritize operational effectiveness without compromise. It stands out in any environment, ensuring seamless integration into existing processes while increasing overall productivity.

This exchange represents the pinnacle of current engineering capabilities, a product that is eager to meet and exceed the needs of modern industrial applications. Its powerful design covers dedication to excellence and advancements in innovation that the industry needs to thrive today.