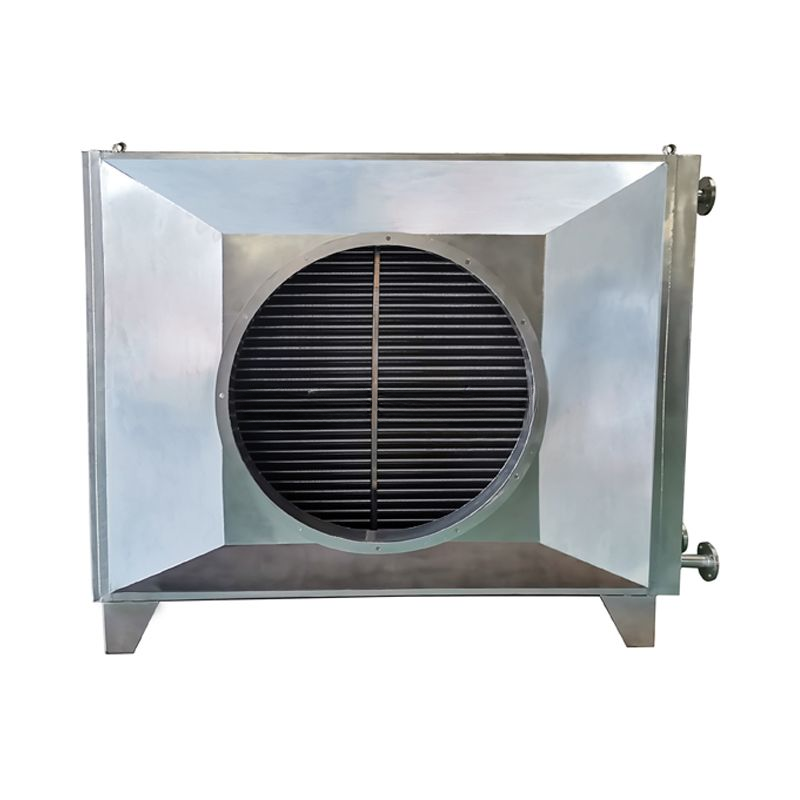

Introduction to the natural gas waste recovery unit

The natural gas waste recovery unit is quickly becoming the cornerstone of the pursuit of energy efficiency in various industries. By leveraging the latest waste heat recovery technology, businesses can capture and reuse otherwise lost heat energy, improve operations and contribute to environmental protection. These innovative systems can provide thermal efficiency up to 85%, proving their potential to transform factories, power plants and other industrial applications into sustainability models.

How does the gas-to-gas waste unit work?

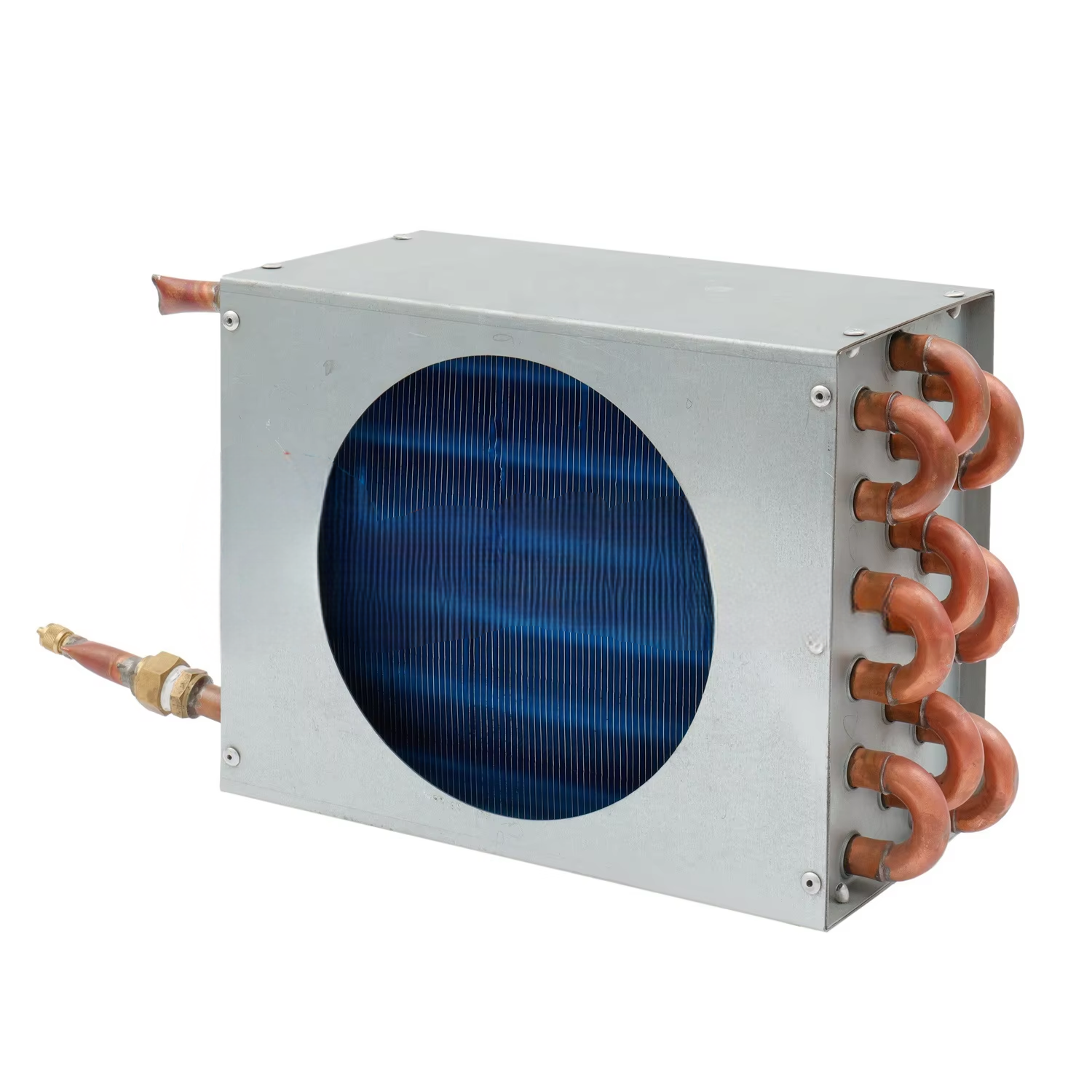

The principle of gas to gas waste heat recovery units is their ability to recover heat from exhaust gas and reuse it in other processes within the facility. This is especially beneficial in large manufacturing units and power plants that release a lot of heat during operation. These systems use state-of-the-art thermal efficiency techniques to effectively capture, store and transfer heat. With energy-efficient solutions, the industry not only reduces its energy consumption, but also reduces greenhouse gas emissions, thus benefiting the environment.

Integrated AI-driven systems are often used in modern wastewater recycling facilities. These systems monitor emissions, regulate temperature profiles, and monitor operations in real time. They ensure optimal performance and make the implementation of industrial thermal recovery systems easier and more efficient. Facilities equipped with these technologies can save a lot of money on energy costs while achieving greener, cleaner production.

Application of waste heat recovery technology

Gas waste recycling systems have been found in a variety of industries, including steel manufacturing, cement production and power generation. They are ideal for facilities with high temperature operation and maximize waste heat utilization. Advanced designs, such as cooling towers with optimized airflow management or chimneys for emission control, reflect how the factory coordinates the production process with environmental management.

For example, power plants equipped with waste heat recovery units become a model for sustainable energy production. This facility utilizes integrated delivery systems to raw materials, minimizing downtime while effectively changing waste energy. In addition, the turbine chamber and storage area are seamlessly organized to further improve operational efficiency. When used in conjunction with renewable energy systems and carbon capture technology, the hours generated per kilowatt-hour reflect the future of sustainable energy.

The benefits of using wastewater recycling system

Using gas-to-gas waste heat recovery systems opens the door to environmental and economic advantages. With thermal efficiency of up to 85%, the industry can significantly reduce its energy costs while taking steps to reduce its carbon footprint. These systems offer a dual advantage: enhance thermal recovery and promote waste heat utilization to support cleaner planets.

Companies working with reliable thermal recovery systems suppliers are ideal for adopting these innovations and enhancing their environmental practices. Furthermore, the symbiotic relationship between industrial areas and the pristine environment highlights how responsible energy solutions coexist in harmony with nature. Advances in landscaping and architectural design show how industrial operations can contribute to the aesthetics and health around them.

The Future of Energy-Saving Facilities

Gas-to-gas waste recovery unit represents an important leap towards smarter and greener energy systems. Businesses aiming to improve thermal efficiency must recognize the transformational potential of waste heat recovery technology. With AI integration, carbon capture systems, etc., the path forward is increasingly promising for industries dedicated to sustainability.

Looking forward, these systems are statements of human ability to innovate responsibly. From preserving resources to shaping sustainable landscapes, gas exhaust gas recycling technologies are crucial to developing a cleaner and brighter energy future.