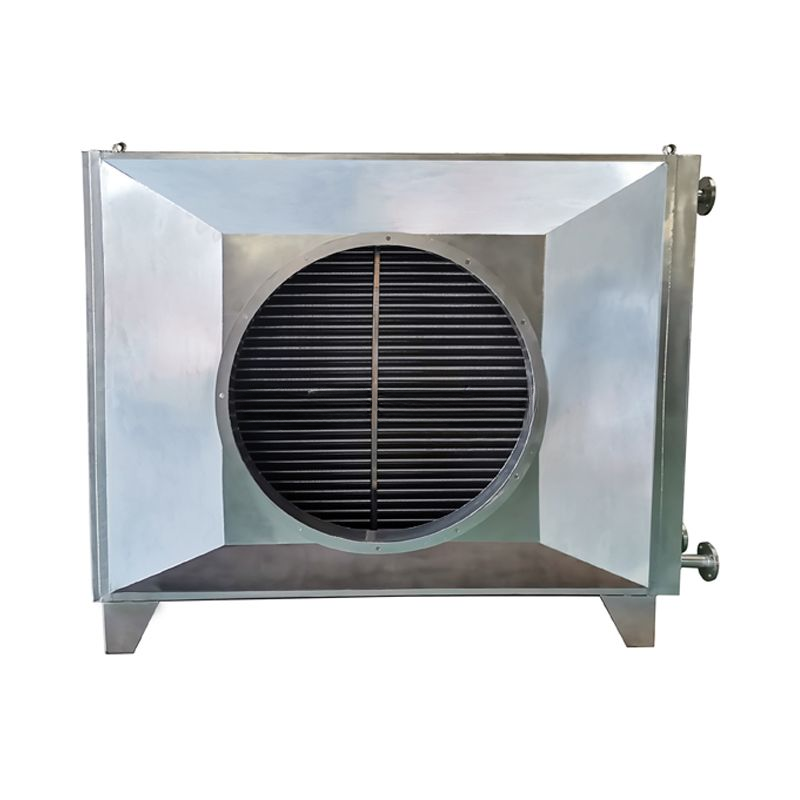

What is a fin tube radiator?

When discussing advanced heat transfer systems, it is impossible to ignore the tube radiator of the fin. The fin tube radiator is designed with its core to increase thermal efficiency by increasing the surface area that can be used for heat exchange. Whether used in residential heating systems or industrial settings, these radiators are staples in the world of high-performance thermal solutions. With designs tailored to a wide range of applications, they provide an excellent choice for traditional radiators, especially in industries where effective heat dissipation is required.

Fin tube radiator design and benefits

The Fin radiator design is designed to maximize heat output by using fins to extend from the pipe to increase the surface interaction with the surrounding air or fluid. This enhanced surface area significantly enhances the heat transfer process. Apart from design efficiency, one of the key benefits of fin tube radiators is their ability to maintain performance while taking up less space, making it ideal for compact installations.

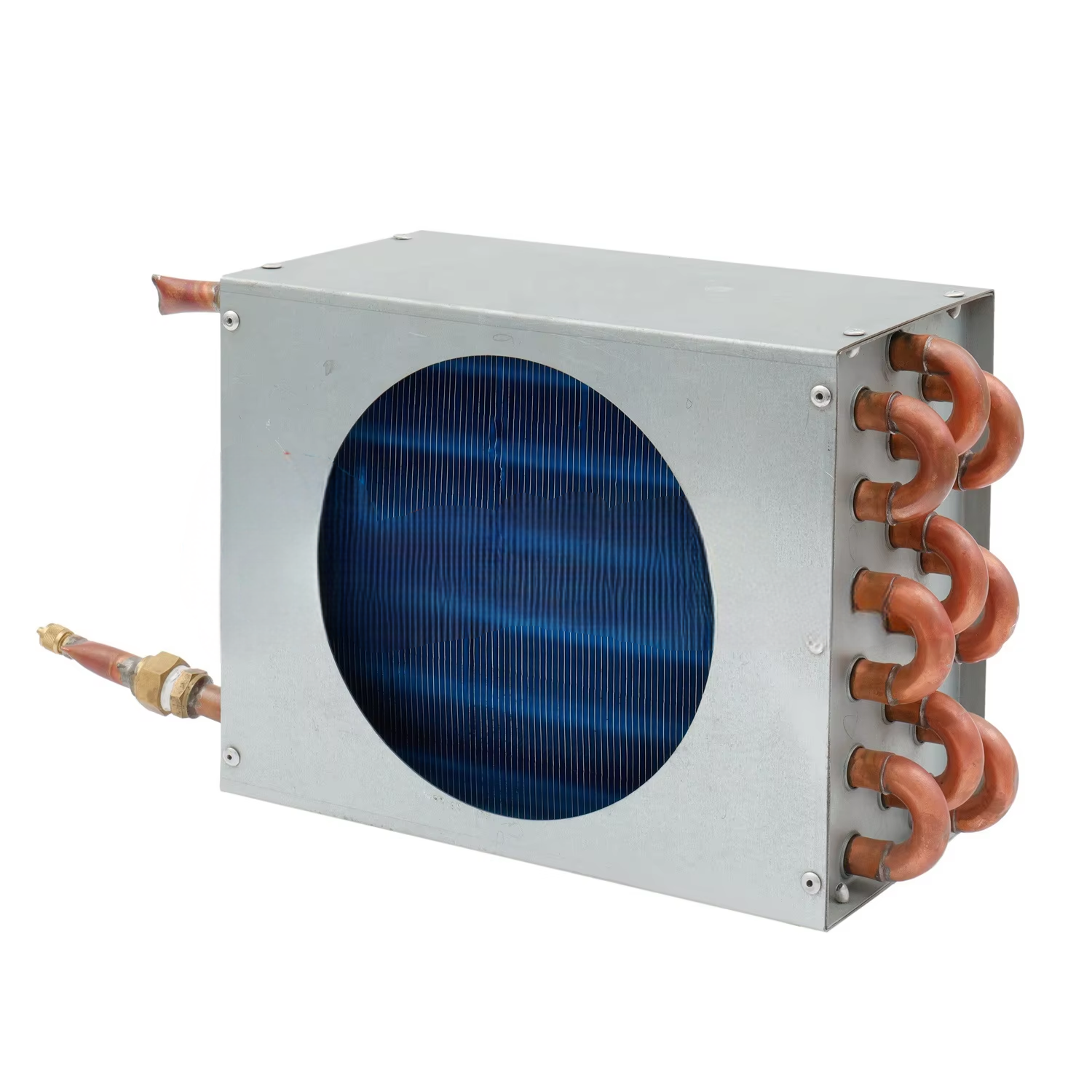

In addition, from HVAC systems to industrial processes such as thermal recovery in power plants, fin tube radiators have a wide range of applications. Their adaptability ensures seamless integration into a variety of systems, whether for heating or cooling purposes. With their durable construction (usually with stainless steel, copper alloy or titanium), they expect life and reliability even under extreme conditions.

Fin tube radiator efficiency and industrial condenser

Subtle but important differences occur when comparing the efficiency of a fin tube radiator with that of an industrial condenser. Thermaltech Solutions' industrial condensers showcase excellent specifications such as heat transfer coefficients up to 6000 W/m²·K and compact designs for space constraint facilities. These features revolutionize industrial operations, especially by enabling high voltage and temperature management.

On the other hand, in applications where distributed heating or cooling is required, fin tube radiators are unparalleled. Their ability to handle multiple fluids, whether it is steam, refrigerant or chemical vapor, makes them an ideal complement to facilities that require local heat exchange. While industrial condensers emphasize large-scale practicality in sectors such as power generation and chemical processing, fin tube radiators are good at smaller scale applications and residential systems. Both are essential in heat transfer. However, the choice between them depends on the scope and requirements of the operation.

Fin tube radiator installation and application

A striking similarity between fin tube radiators and industrial condensers is their direct installation process. The installation of Finned Tube heatsinks is often simplified by a modular design and compact configuration, so that it can be integrated into existing settings with minimal modifications. Similarly, Thermaltech solutions emphasize the maintenance of its condensers through features such as movable tube bundles.

The applications of fin tube radiators cover HVAC, refrigeration and industrial heating systems, in which space efficiency and high performance are crucial. Industrial fin radiators further expand their capabilities by supporting heavy duty operations such as thermal recovery and high-demand cooling environments. These radiators thrive in the need of a strong and reliable heat exchange mechanism, and prove to be essential in many industrial and commercial spaces.

Select the right solution

For industries requiring large-scale, high-pressure operation, Thermaltech Solutions' industrial condensers may be the most suitable. Its technology mastery and compliance with global standards is a leader in heat transfer solutions. At the same time, companies seeking effective local heating or cooling systems should consider fin tube radiators. Compared to oversized devices, its compact design and versatility make it a powerful candidate.

All in all, whether it is about fin tube radiator efficiency or the cutting-edge features of Thermaltech Solutions industrial condensers, it is crucial to understand the key differences and benefits of each system. Choosing between these two powerful heat transfer solutions can turn your operations into a sustainable and cost-effective process by analyzing your specific needs and scope of application.