Introduction to Heat Exchanger

In the field of industrial operations, the term “fin tube heat exchanger” is often surfaced as a staple for discussions around thermal management and energy efficiency. These devices play a key role in transferring heat between fluid media, ensuring optimal operating conditions for countless industries. The emergence of advanced models, such as welding plate heat exchangers, highlights the transformative waves that travel through the sector, characterized by increased performance and sustainability.

Revealing Welding Plate Heat Exchanger

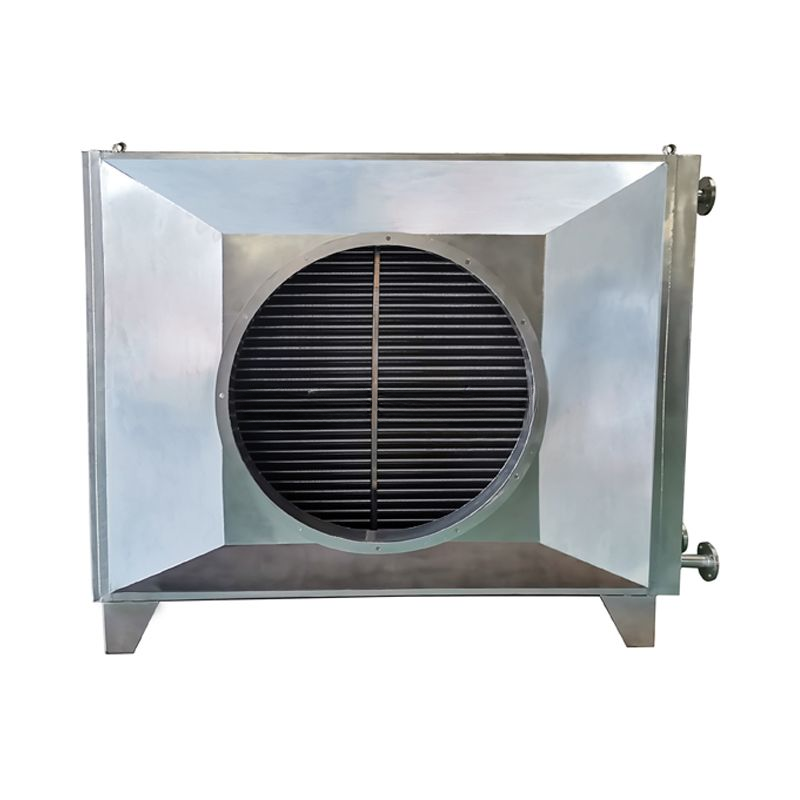

Welded plate heat exchangers represent a major leap in industrial heat exchange technology. The device is made of high-quality stainless steel, which not only has a rust-free appearance, but also has an aesthetic appeal that is rare in industrial equipment. The smooth design matches the complex welded steel plate array to maximize heat transfer efficiency. This ensures not only high heat exchange rates, but also unparalleled reliability in the most demanding environments, including chemical processing, oil refining and HVAC systems.

Innovative design and functions

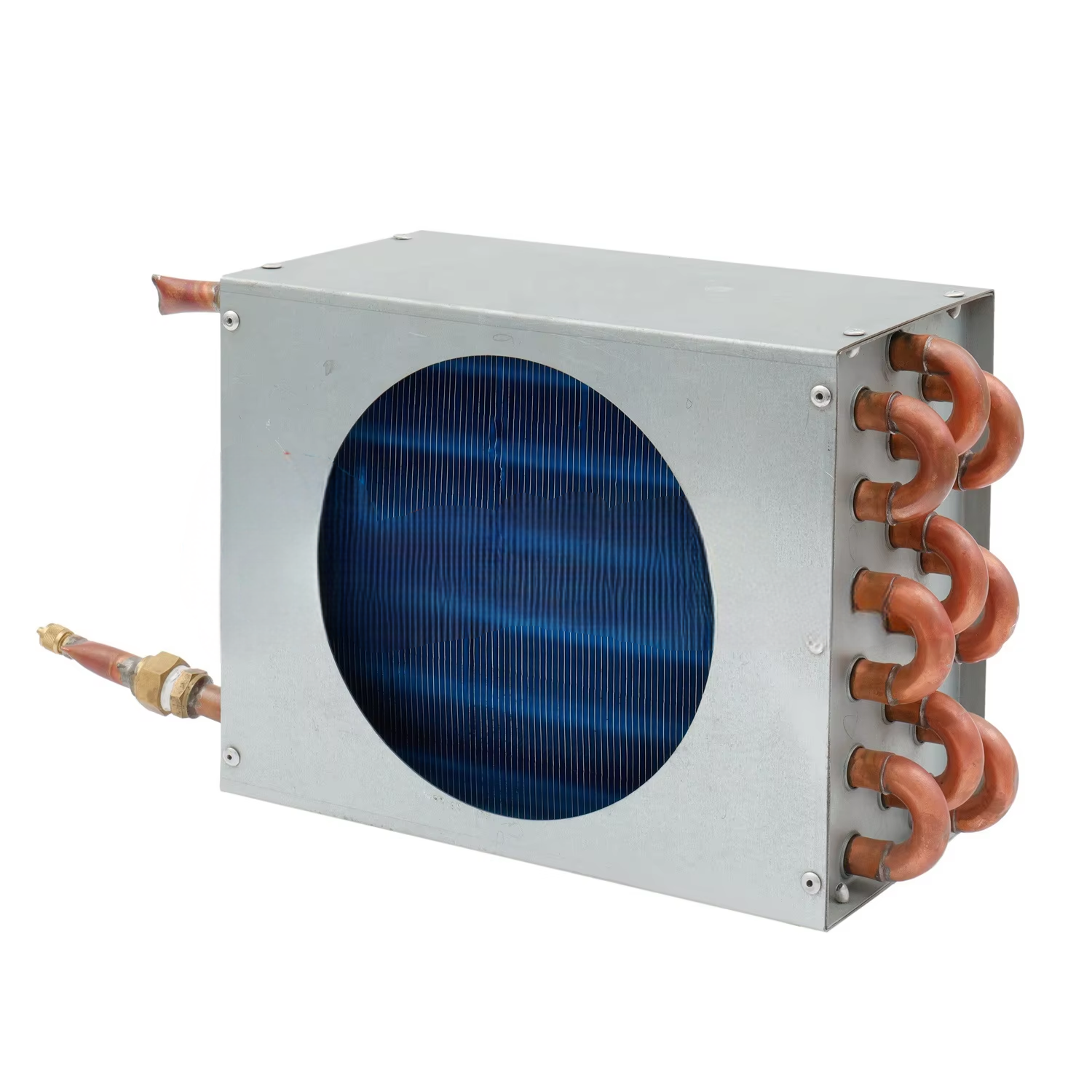

What makes the welded plate heat exchanger unique is its innovative modular structure. This feature allows for excellent adaptability, allowing businesses to adjust their heat exchangers to specifically address their operational needs. At the heart of the design is the carefully designed blue flange cover. These are not only for aesthetics; they provide seals and ensure seamless integration with existing systems. This, in turn, saves energy and enhances overall system stability. Such features ensure that all departments can operate smoothly and effectively, reducing operational obstacles and reduced maintenance time.

Hot transfer optimized for advanced corrugated paper design

The excellent feature of this heat exchanger is the advanced corrugated design in its board. This design induces turbulence inside the transmitted fluid, thereby increasing surface area contact between the fluid media. The result is a significant reduction in maximum heat transfer with energy consumption. This increased efficiency is a boon for sustainable industrial operations, allowing businesses to reduce not only operating costs but also their carbon footprint. This environmentally friendly approach positions welded plate heat exchangers as the industry's leading solution for priority sustainability.

Easy to maintain and long-term benefits

In addition, easy maintenance is another hallmark of welding plate heat exchangers. The modular board design ensures minimal downtime as the system can be easily accessed and maintained without the need for a large number of disassembly. This capability is especially beneficial in industries where continuous operations are critical and any disruption can lead to significant financial losses. By promoting fast, direct maintenance, this heat exchanger can minimize operational disruptions and extend installation life, proving itself to be a cost-effective and lasting option for long-term industrial applications.

Conclusion: The Future of Industrial Heat Exchange

As the industry develops, the demand for advanced, efficient and sustainable solutions continues to grow. Welded plate heat exchangers demonstrate innovation, embodying a forward-looking approach that aligns with modern industrial needs. It combines powerful features, ease of maintenance and commitment to energy efficiency, which is a compelling choice for businesses looking to improve operational performance while embracing sustainability. By investing in this cutting-edge technology, the industry not only improves current operations but also improves the future process for the ever-changing industrial landscape. Welded plate heat exchangers are more than just products. It is a strategic asset that improves efficiency and reduces costs, guiding companies to achieve a sustainable future.