Finally change industrial efficiency through waste heat recovery

In today’s world, promoting sustainability and optimizing energy consumption has never been more powerful. **Innovations such as gas waste recovery units pave the way for pioneering advances in thermal efficiency systems. This technology allows the industry to minimize energy waste by repurposing energy waste, thereby obtaining substantial savings and reducing its carbon footprint. With waste heat technology, the industry can now convert previously lost heat into useful energy, supporting environmental goals and reducing operating costs.

Experience behind advanced thermal recovery systems

Industry leaders are always looking for energy efficiency solutions that provide sustainable return on investment. **Mechanical vapor recompression (MVR) evaporation systems and other products** emphasizes how far the innovation capability is. These systems have advanced turbocharged and centrifugal compressor designs that meet a variety of industrial needs. From chemical plants to food processors, MVR technology provides thermal efficiency up to 85%, significantly better than older systems. By adopting this industrial thermal recovery solution, companies avoid wasting energy, which directly contributes to their bottom line and environmental management.

The benefits of decomposing gases into gas systems

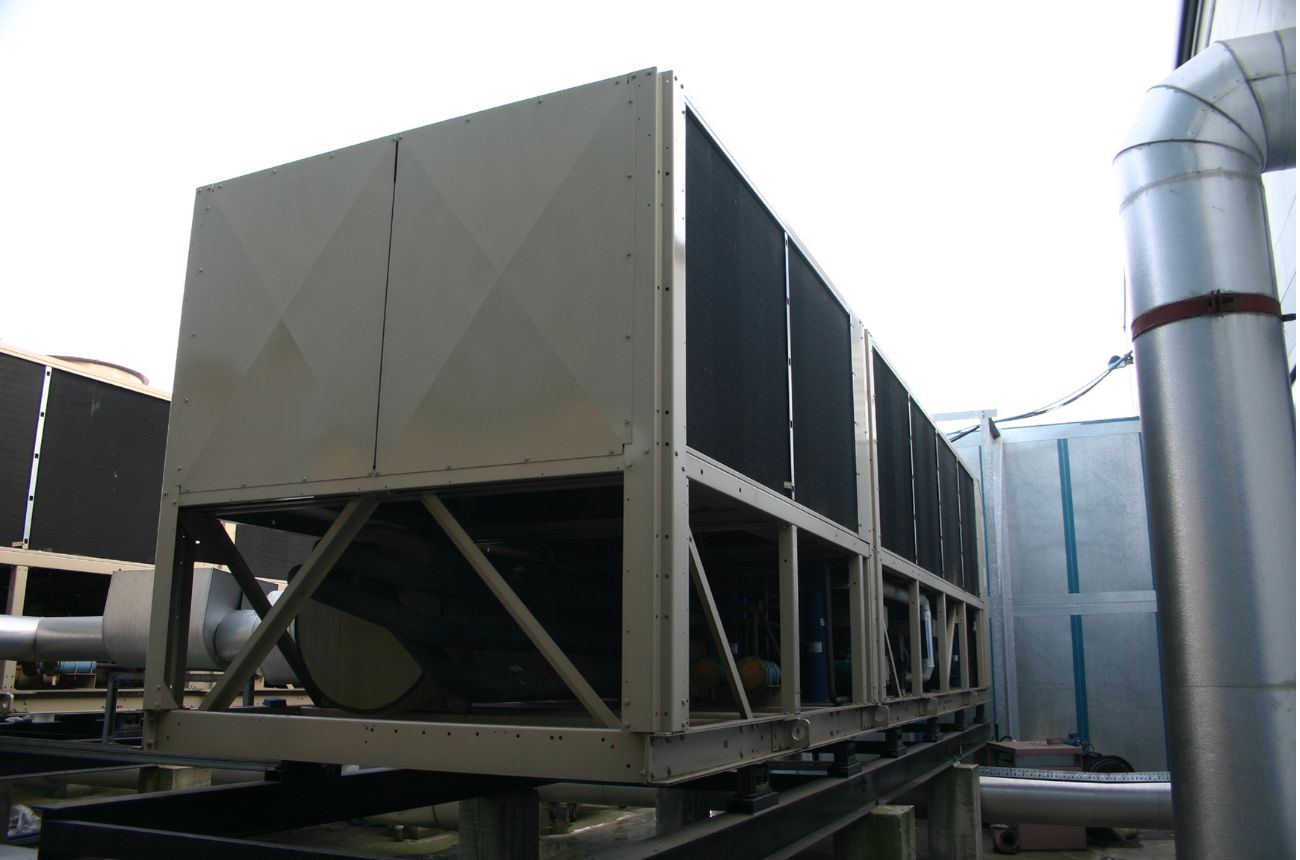

The core of these thermal recovery systems is the focus on optimizing energy utilization. **Gas-to-gas waste heat recovery unit** seamlessly integrates with a range of industrial operations, thus surpassing energy savings. Imagine achieving energy recovery of up to 85% is a substantial advance that directly affects profitability while bringing the industry closer to achieving its sustainability goals. By leveraging thermal energy recovery, the company is heading towards a more efficient future, where waste heat utilization becomes the cornerstone of its operations.

Customized solutions for specific industry needs

One size does not fit all industries, and the MVR evaporation system demonstrates this by providing highly customizable configurations. From mining wastewater management in zero-liquid emission systems to improving sanitary whey concentrations in dairy products, these systems adapt to unique requirements. When your thermal recovery system supplier can directly meet the specific needs of your industry, you not only save energy, but also gain a competitive advantage. As real-world success stories have repeatedly proven, the implementation of strategic implementation of industrial thermal recovery can fundamentally change operational efficiency.

Smart Technology for a Sustainable Future

With advances such as AI optimization and industry 4.0 integrated systems, the future of waste heat recovery technology is smarter than ever. Modern systems now have remote troubleshooting and predictive maintenance capabilities to ensure downtime and maximum uptime. These systems are equipped with digital dual technology and vibration sensors, ushering in an era of intelligent energy management. Furthermore, their ability to significantly reduce water waste and emissions ensures compliance with ESG obligations, which is a victory for the planet and the industries that adopt them.

Why is important: Beyond operating efficiency

The adoption of systems such as natural gas waste recovery units represents a commitment to a greener, more effective future. As energy efficiency solutions move towards sustainability, no industry should be abandoned. By marrying advanced engineering, tailor-made solutions and smart technologies, these systems redefine the possibilities of industrial efficiency. As businesses explore these breakthrough solutions, they not only discover operational benefits, but also opportunities to contribute to global environmental goals. Whether through cost reduction or ESG compliance, the advantages are obvious. The future is here, it is energy-saving.