Introduction to Fin Tube Heat Exchanger

Fin tube heat exchangers are an essential component in thermal management systems and can effectively transfer heat in a variety of industrial and commercial applications. Their design combines heat sinks that increase heat transfer to the surface area, thereby improving performance and energy efficiency. Fin tube heat exchangers are a multifunctional solution for systems requiring precise control of thermodynamics.

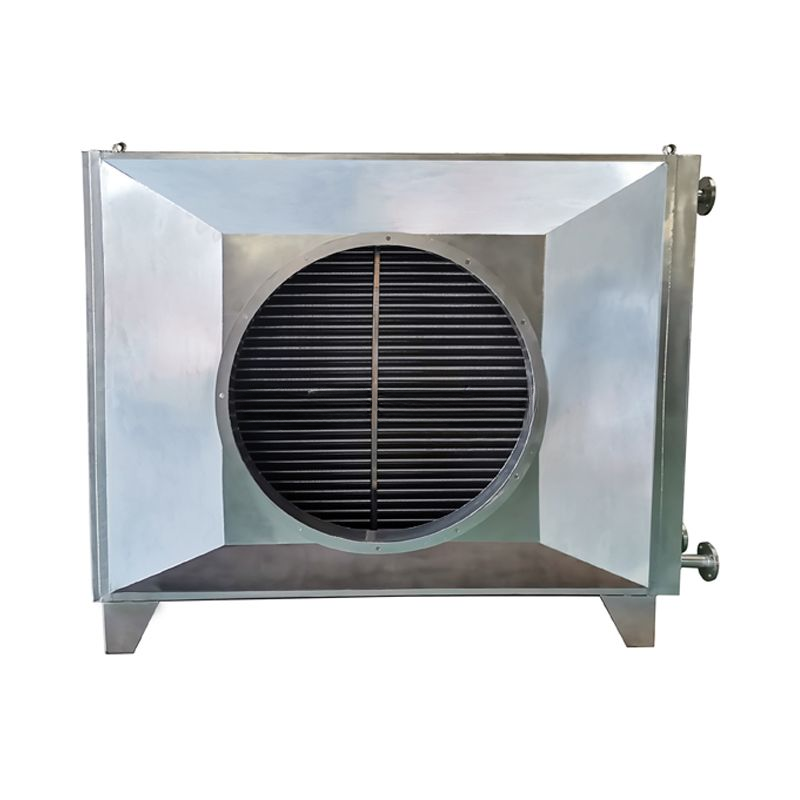

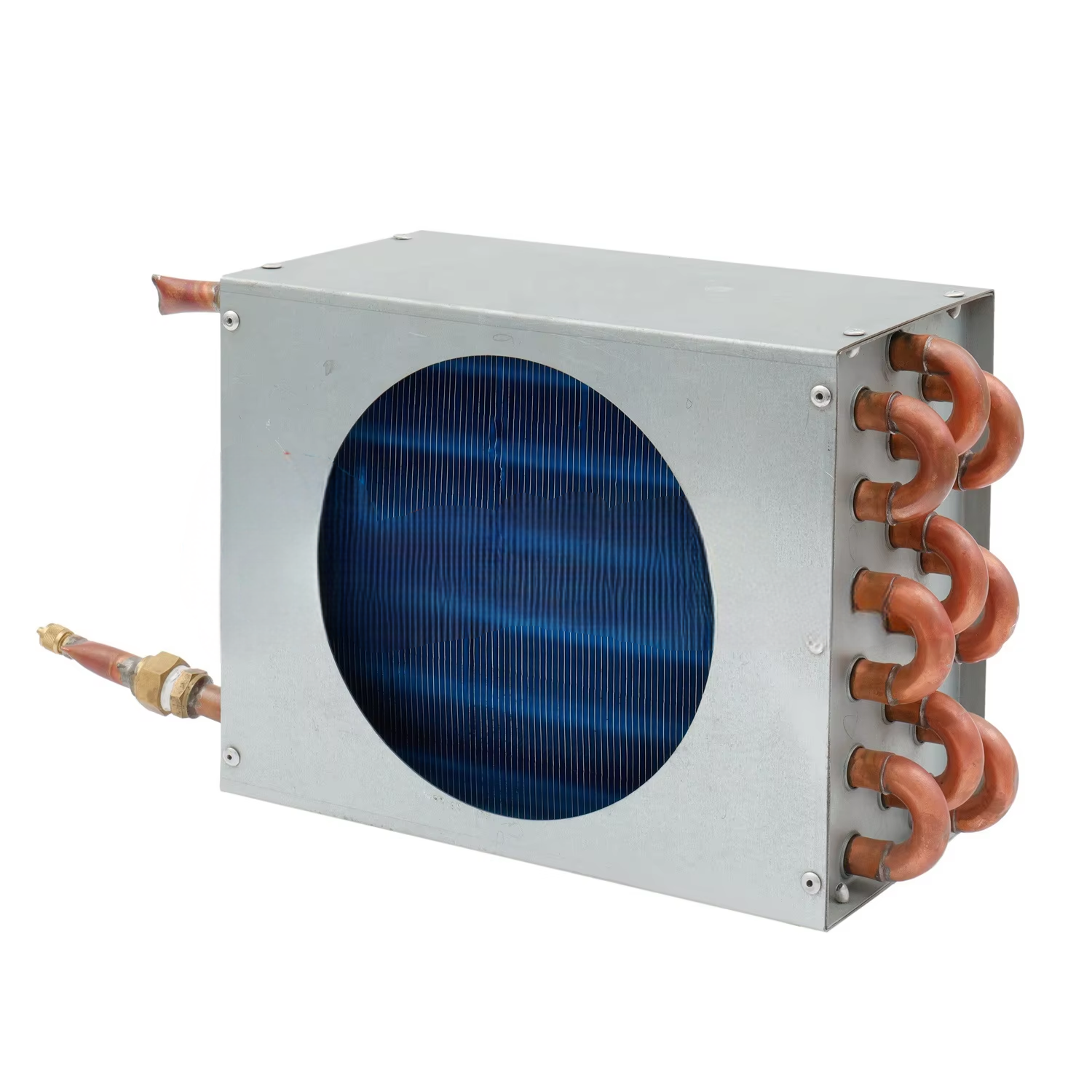

Innovative design of heat exchanger module

The cutting-edge heat exchanger module embodies advanced engineering and innovation in thermal management. The module, created to withstand harsh conditions, is wrapped in corrosion-resistant aluminum to ensure life and durability. The industrial design features carefully arranged horizontal fins that optimize air flow and enhance heat dissipation. This configuration improves thermal efficiency while reducing energy consumption, making it an environmentally friendly option for a variety of settings.

The external design of this module is both powerful and visually appealing, allowing it to be seamlessly integrated into contemporary or traditional infrastructure. This makes the heat exchanger module ideal for a wide range of applications from data centers to HVAC systems and energy systems in greenhouses.

Verifiability and customization

One of the outstanding features of the heat exchanger module is its modular design that provides simple integration and maintenance. Industrial, commercial buildings and residential areas can benefit from their adaptable nature, effortlessly adapting to various spatial limitations. The durability of the product is ensured by its precise construction, including riveted joints, enhancing its ability to withstand harsh conditions.

In addition, customers can freely customize modules to meet specific requirements, ensuring that the system not only meets but exceeds expectations. It offers unparalleled efficiency and cutting-edge technology solutions that are worth investing for any business or individual seeking to improve their thermal management systems.

Application of Fin Tube Heat Exchanger

Fin tube heat exchangers are particularly advantageous in applications where space is limited but require a lot of heat transfer. They are crucial in areas such as manufacturing, power generation, heating, ventilation and air conditioning (HVAC). Furthermore, they contribute to energy efficiency and environmental initiatives that align with modern trends in sustainable practices.

In manufacturing, they help cool machinery, reduce wear and improve operating life. In power generation, they optimize the efficiency of the power plant by providing the necessary cooling. The HVAC system benefits from its ability to effectively maintain ambient temperature. In greenhouses, they regulate temperature and humidity levels, thereby promoting better crop growth.

Conclusion

In short, the heat exchanger module using fin tube heat exchangers provides a comprehensive solution to the thermal management challenges. Its state-of-the-art design ensures high performance, durability and versatility, suitable for a wide range of applications. The product embodies innovation that enables the industry to thrive while supporting environmental and energy-saving practices. With the continued development of thermal management technology, heat exchanger modules are still at the forefront, paving the way for the sustainable development of heat exchange systems.