The Challenge of Industrial Thermal Management

Inefficient thermal management poses a significant challenge across numerous industries, from chemical processing and power generation to food and beverage production. Uncontrolled or poorly managed temperatures can lead to increased operational costs due to excessive energy consumption, reduced process yields, compromised product quality, and even safety hazards. The quest for reliable and effective heat transfer equipment is therefore paramount for maintaining operational efficiency, competitiveness, and sustainability. Among the various solutions designed to tackle these thermal challenges, the shell and tubular heat exchanger has long been recognized for its robustness, versatility, and proven performance in a multitude of applications.

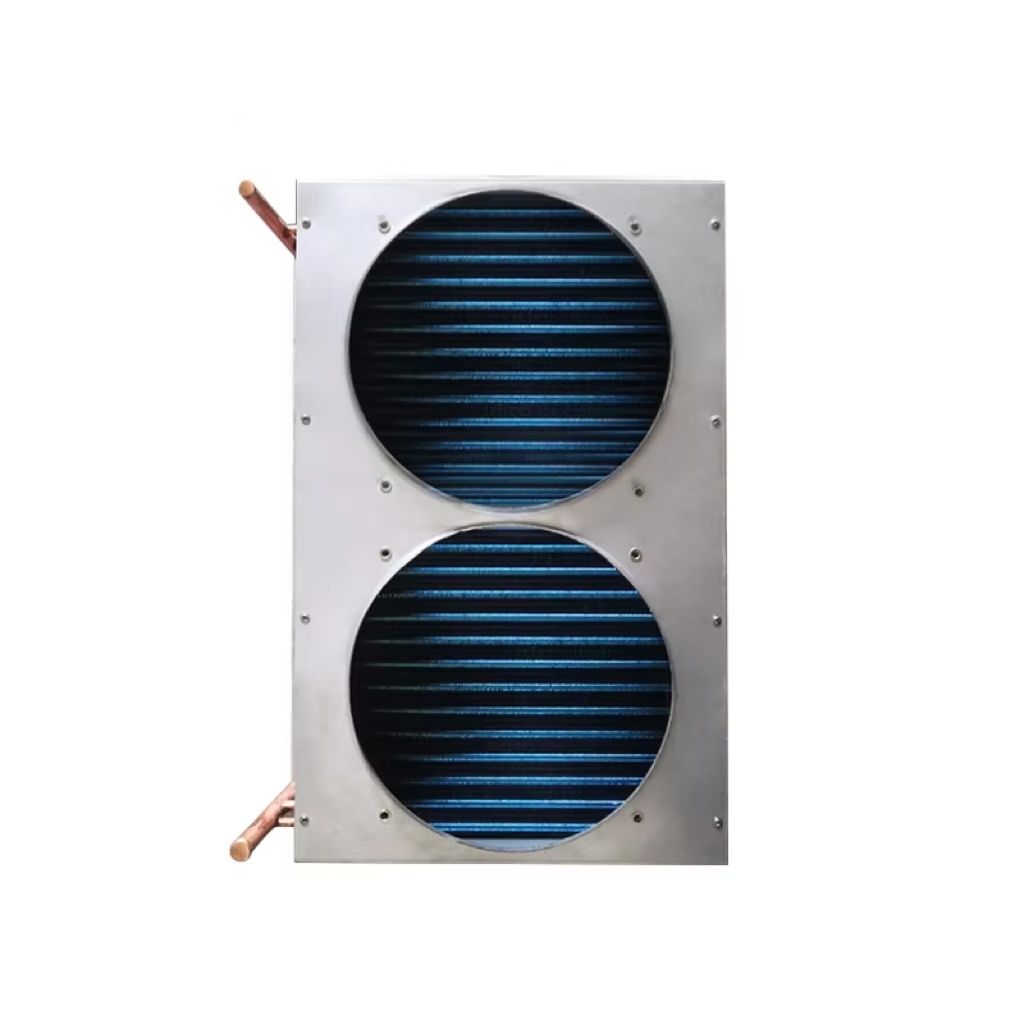

Understanding Shell and Tubular Heat Exchangers

At its core, a shell and tubular heat exchanger is a specialized device designed to transfer heat between two or more fluids without them coming into direct contact. The primary construction involves a series of tubes housed within a larger cylindrical shell. One fluid flows through these tubes, while the other fluid flows over the tubes within the shell. This arrangement facilitates efficient heat transfer from the hotter fluid to the cooler fluid through the tube walls. These units are a cornerstone in the realm of industrial heat exchangers, capable of handling a wide range of temperatures, pressures, and fluid types, including liquids, gases, and vapors. Their fundamental design allows for effective heating, cooling, condensation, or evaporation, making them indispensable in optimizing thermal energy usage.

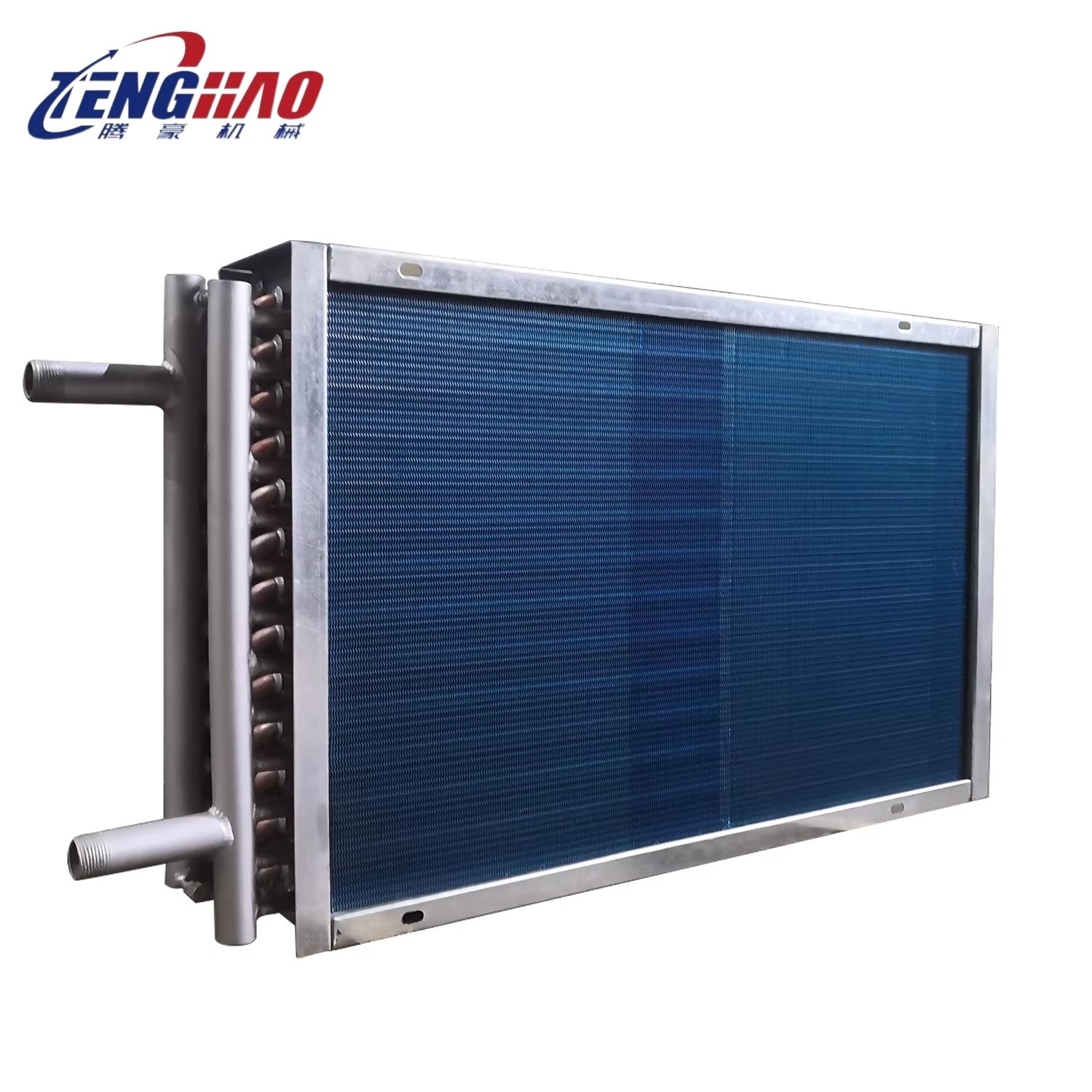

Critical Tubular Heat Exchanger Features

Several key tubular heat exchanger features contribute to their widespread adoption and effectiveness. Their design flexibility is a major advantage; they can be constructed from various materials like carbon steel, stainless steel, titanium, or other alloys to suit specific corrosive environments or temperature requirements. The number, size, and arrangement of tubes can also be customized to optimize heat transfer rates and minimize pressure drop. Furthermore, many designs allow for easy cleaning and maintenance, with removable tube bundles that simplify inspection and repair, thereby reducing downtime. This adaptability ensures that they can be tailored to meet the precise thermal duties of diverse industrial processes, offering longevity and reliability.

Achieving Superior Heat Exchanger Control

One of the most significant benefits offered by a well-designed shell and tubular heat exchanger is the potential for superior heat exchanger control. By carefully engineering the flow paths, surface area, and material properties, these exchangers allow for precise regulation of outlet temperatures for both fluid streams. This level of control is crucial for processes where temperature stability directly impacts product quality, reaction rates, or energy efficiency. Sophisticated designs might incorporate baffling systems within the shell to direct the shell-side fluid flow effectively across the tubes, enhancing the heat transfer coefficient and improving overall thermal performance. Achieving such control translates directly into optimized energy consumption, reduced waste, and more consistent operational outcomes, reinforcing the value of a quality shell and tubular heat exchanger.

The Mark of Quality: Advanced Heat Exchanger Design

When selecting a heat exchanger, it's crucial to consider the engineering and manufacturing quality to ensure long-term performance and reliability. Advanced designs focus not only on thermal efficiency but also on durability, ease of maintenance, and adherence to stringent industry standards. A TECNIC heat exchanger, for instance, often embodies these principles through careful material selection, precision manufacturing, and innovative design enhancements aimed at maximizing heat recovery and minimizing fouling. Investing in such high-quality units ensures that industries can achieve optimal thermal performance, reduce operational expenditure through energy savings and lower maintenance needs, and ensure process safety. The focus on continuous improvement and technological advancement is what sets apart leading heat exchanger solutions.

Your Solution for Efficient Heat Transfer

In conclusion, the challenges of industrial thermal management demand robust and efficient solutions. The shell and tubular heat exchanger stands out as a highly effective and adaptable piece of heat transfer equipment, capable of addressing a vast array of heating and cooling requirements across various sectors. Its ability to provide reliable performance, coupled with features that allow for superior control over thermal processes, makes it an invaluable asset for any operation looking to enhance efficiency, reduce energy costs, and ensure process stability. By understanding its fundamental principles and the benefits of advanced designs, industries can confidently implement the shell and tubular heat exchanger to overcome their thermal management hurdles and pave the way for smoother, more economical operations.