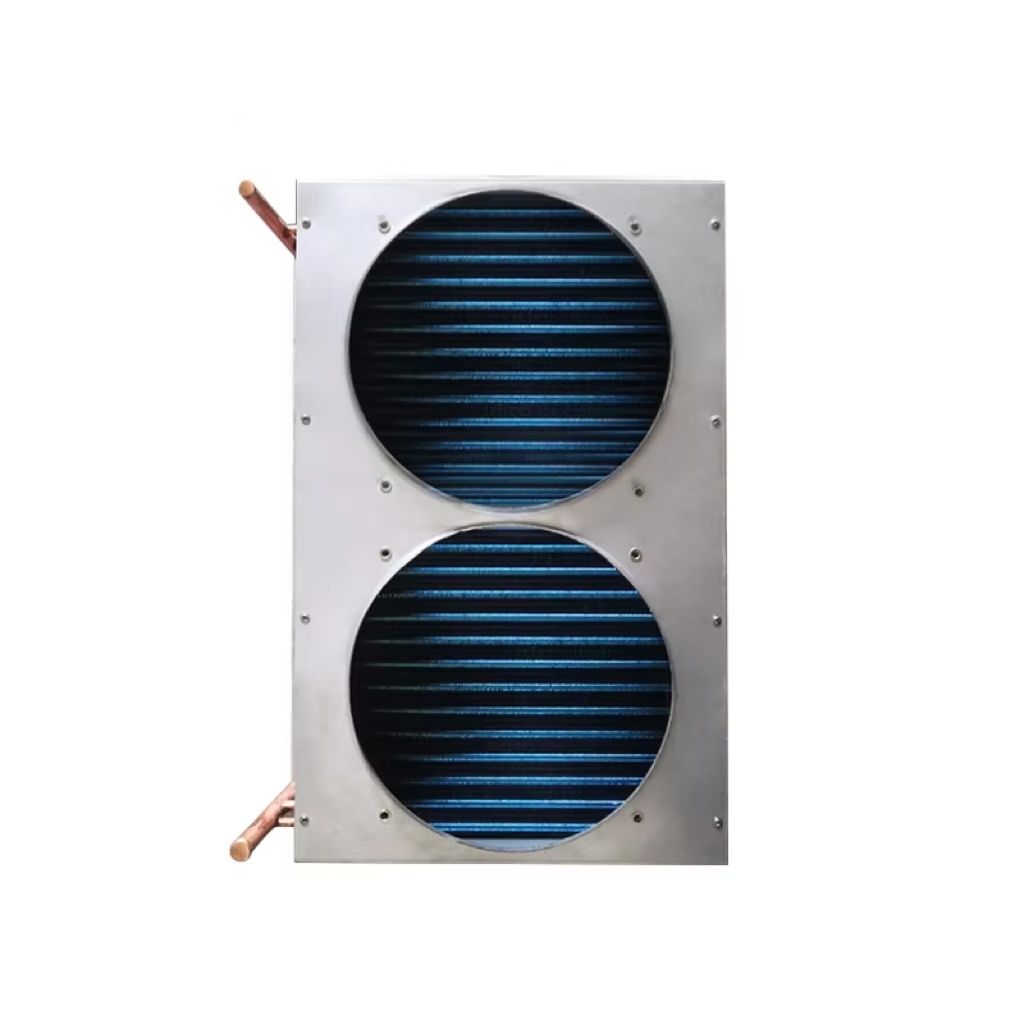

Introduction to Finned Tube Heat Exchangers

Finned tube heat exchangers are pivotal components in the oil and gas industry, facilitating efficient heat transfer processes. As the demand for oil and gas heat exchangers increases, industries turn towards finned tube technology for enhanced thermal management. The use of welded finned tube heat exchangers has revolutionized heat transfer solutions in this sector, making it indispensable for oil and gas processing equipment.

Significance of Material Selection

The choice of materials in the design of finned tube heat exchangers is crucial for optimal performance. High-performance materials such as stainless steel, titanium, and Hastelloy are often employed due to their ability to withstand corrosive environments common in the industry. Stainless steel varieties like 304 and 316L offer resistance against general corrosion, making them suitable for tasks like water-to-water heat transfer and food processing. For environments exposed to seawater or strong acids, titanium becomes the material of choice despite its higher cost. With its capability to endure temperatures up to 200°C, it serves well in chemical and pharmaceutical scenarios. Hastelloy, renowned for its prowess in extreme conditions that involve strong corrosive agents like hydrochloric and sulfuric acid, is particularly preferred in oil refining and electroplating situations.

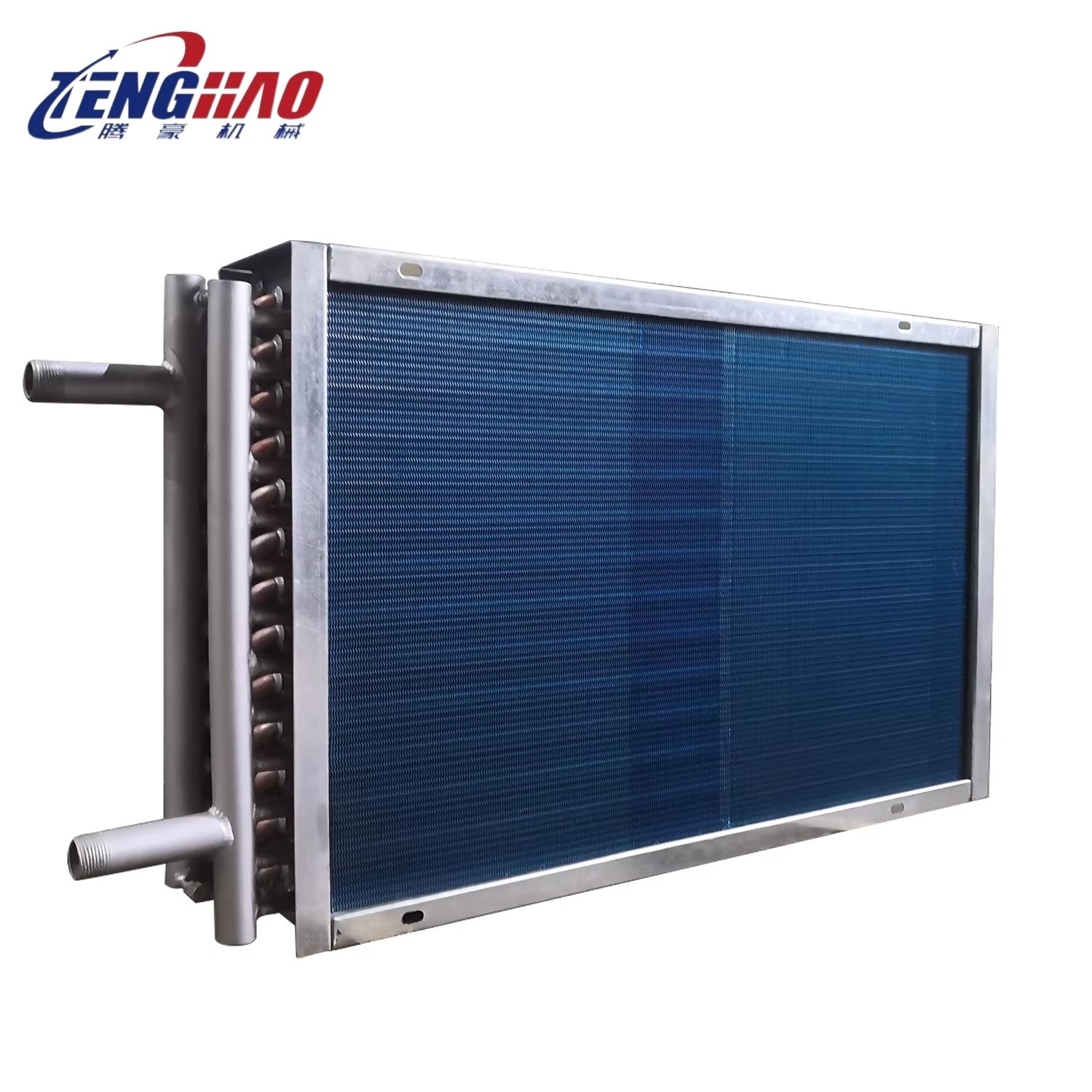

Functional Analysis and Industry Applications

The efficient design of finned tube heat exchangers involves several functional elements tailored to industry-specific demands. Plate corrugations like chevron and herringbone patterns are employed to heighten heat transfer efficiency, surpassing traditional shell-and-tube exchangers by up to five times. These exchangers are designed to be modular and detachable, facilitating easy maintenance and reducing operational costs. Moreover, their compact size makes them an energy-efficient choice, minimizing medium residue and serving effectively in processing thermosensitive fluids like milk and juice.

In terms of performance, finned tube heat exchangers operate within a temperature range of -20°C to 200°C, dependent on the gasket material, and can accommodate working pressures up to 25 bar. They are adaptable to variable flow rates, ranging from 0.2 to 2000 m³/h, achieved through multiple plate assemblies.

Customized designs meet industry-specific needs, such as pharmaceutical-grade mirror-polished plates and FDA-approved gaskets ensuring sterility. In contrast, the chemical sector benefits from titanium plates paired with fluoroelastomer gaskets, capable of processing highly corrosive substances within a pH range of 1-14.

Overall, finned tube heat exchanger designs offer robust and energy-efficient solutions across diverse industries, addressing specific operational demands and adhering to stringent standards to enhance operational longevity and cost-effectiveness.