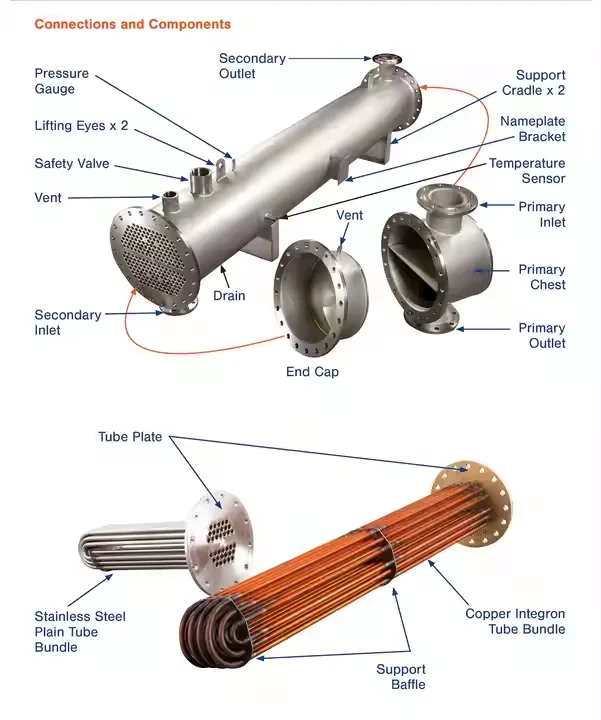

The Shell-and-Tube Heat Exchanger is a highly efficient thermal transfer device designed for industrial heating, cooling,

condensation, and evaporation applications. Its robust construction and versatile design make it ideal for handling high-pressure,

high-temperature, and corrosive fluids across various industries.

Products Description

Shell and tube heat exchanger

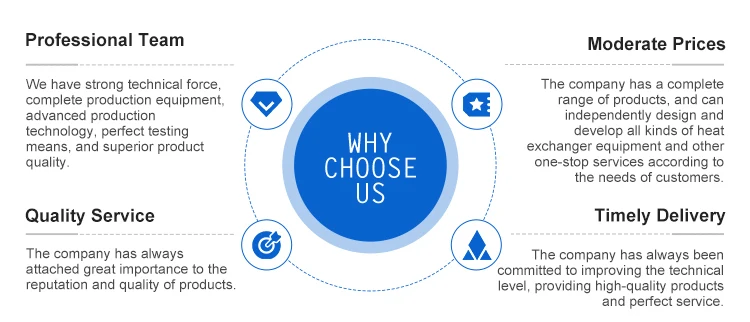

Why Choose Us

Key Features & Benefits

✔ High Thermal Efficiency – Optimized tube layout maximizes heat transfer between fluids.

✔ Durable Construction – Available in carbon steel, stainless steel, titanium, and exotic alloys for corrosion resistance.

✔ Wide Pressure & Temperature Range – Suitable for extreme conditions (up to 600°C & 30 MPa).

✔ Customizable Designs – Fixed tube sheet, U-tube, floating head, and multi-pass configurations.

✔ Easy Maintenance – Removable tube bundles for cleaning and repair.

✔ Energy Savings – Recovers waste heat to reduce operational costs.

✔ Durable Construction – Available in carbon steel, stainless steel, titanium, and exotic alloys for corrosion resistance.

✔ Wide Pressure & Temperature Range – Suitable for extreme conditions (up to 600°C & 30 MPa).

✔ Customizable Designs – Fixed tube sheet, U-tube, floating head, and multi-pass configurations.

✔ Easy Maintenance – Removable tube bundles for cleaning and repair.

✔ Energy Savings – Recovers waste heat to reduce operational costs.

Technical Specifications

ParameterSpecificationsDesign StandardsASME, TEMA, PED, API 660Shell MaterialCarbon Steel, SS304/316, Titanium, Duplex SteelTube

MaterialCopper, Cu-Ni, Inconel, HastelloyPressure RatingUp to 30 MPa (4,350 psi)Temperature Range-50°C to 600°C (-58°F to 1,112°F)

Connection TypesFlanged, threaded, or welded

MaterialCopper, Cu-Ni, Inconel, HastelloyPressure RatingUp to 30 MPa (4,350 psi)Temperature Range-50°C to 600°C (-58°F to 1,112°F)

Connection TypesFlanged, threaded, or welded

Applications

1. Oil & Gas

* Crude oil heating/cooling

* Natural gas processing & LNG heat exchange

* Refinery distillation & hydrocracking

2. Power Generation

* Steam condensers in thermal power plants

* Feedwater heaters for boilers

* Waste heat recovery systems

3. Chemical & Pharmaceutical

* Reactor temperature control

* Solvent evaporation & condensation

* Crude oil heating/cooling

* Natural gas processing & LNG heat exchange

* Refinery distillation & hydrocracking

2. Power Generation

* Steam condensers in thermal power plants

* Feedwater heaters for boilers

* Waste heat recovery systems

3. Chemical & Pharmaceutical

* Reactor temperature control

* Solvent evaporation & condensation

* Distillation & crystallization

4. HVAC & Refrigeration

* Chillers & heat pumps

* District heating/cooling systems

5. Food & Beverage

* Pasteurization of milk & juices

* Brewery & distillery process cooling

6. Marine & Offshore

* Engine cooling system

* Seawater desalination

4. HVAC & Refrigeration

* Chillers & heat pumps

* District heating/cooling systems

5. Food & Beverage

* Pasteurization of milk & juices

* Brewery & distillery process cooling

6. Marine & Offshore

* Engine cooling system

* Seawater desalination

Why Choose Our Shell-and-Tube Heat Exchanger?

✅ Proven Reliability – Engineered for long-term performance in harsh environments.

✅ Custom Solutions – Tailored designs for specific flow rates, pressures, and temperatures.

✅ Global Certifications – Complies with ASME, TEMA, PED, and API standards.

✅ Competitive Pricing – Cost-effective without compromising quality.

✅ Custom Solutions – Tailored designs for specific flow rates, pressures, and temperatures.

✅ Global Certifications – Complies with ASME, TEMA, PED, and API standards.

✅ Competitive Pricing – Cost-effective without compromising quality.

Video presentation

Details Images

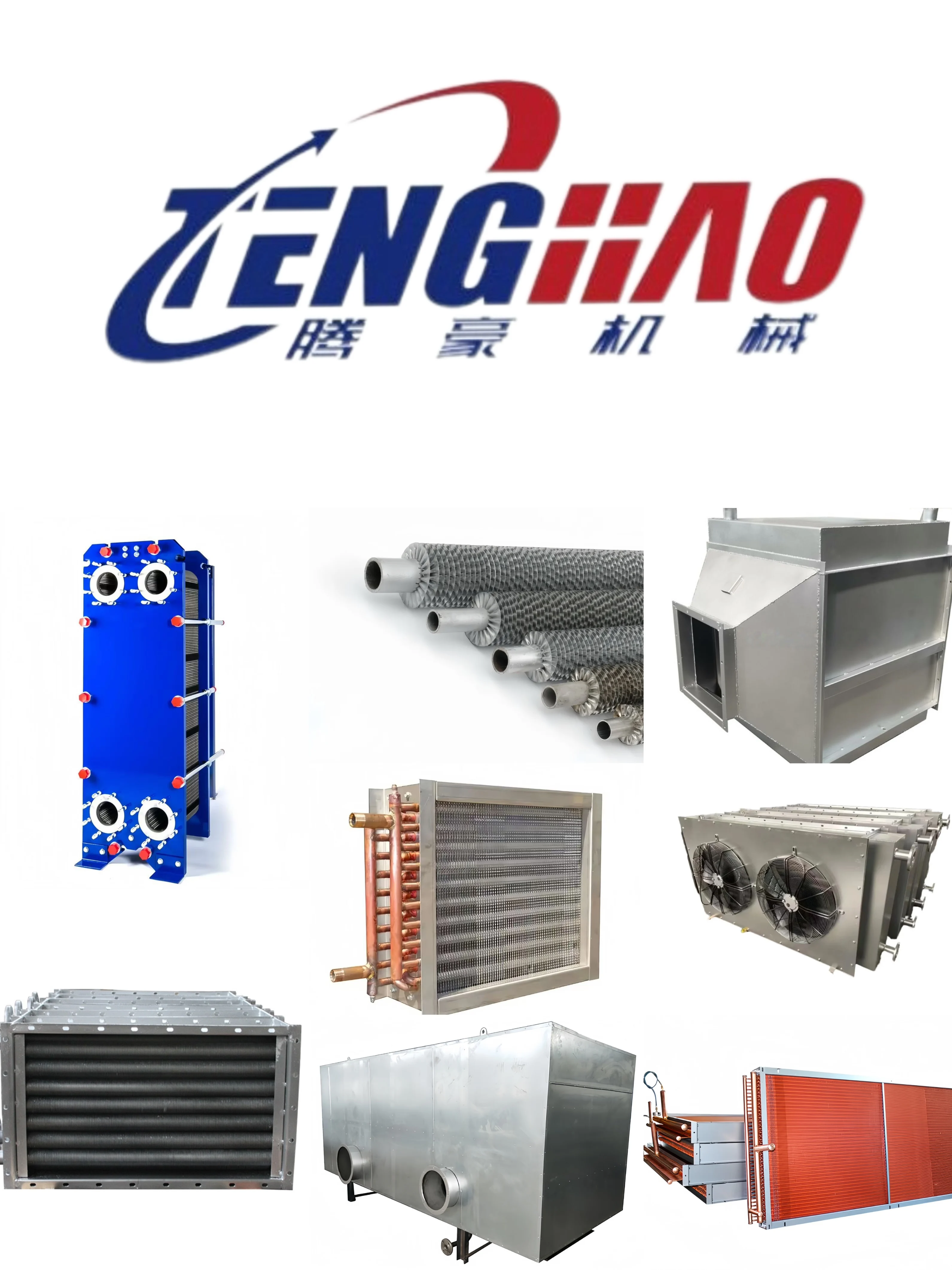

Recommend Products

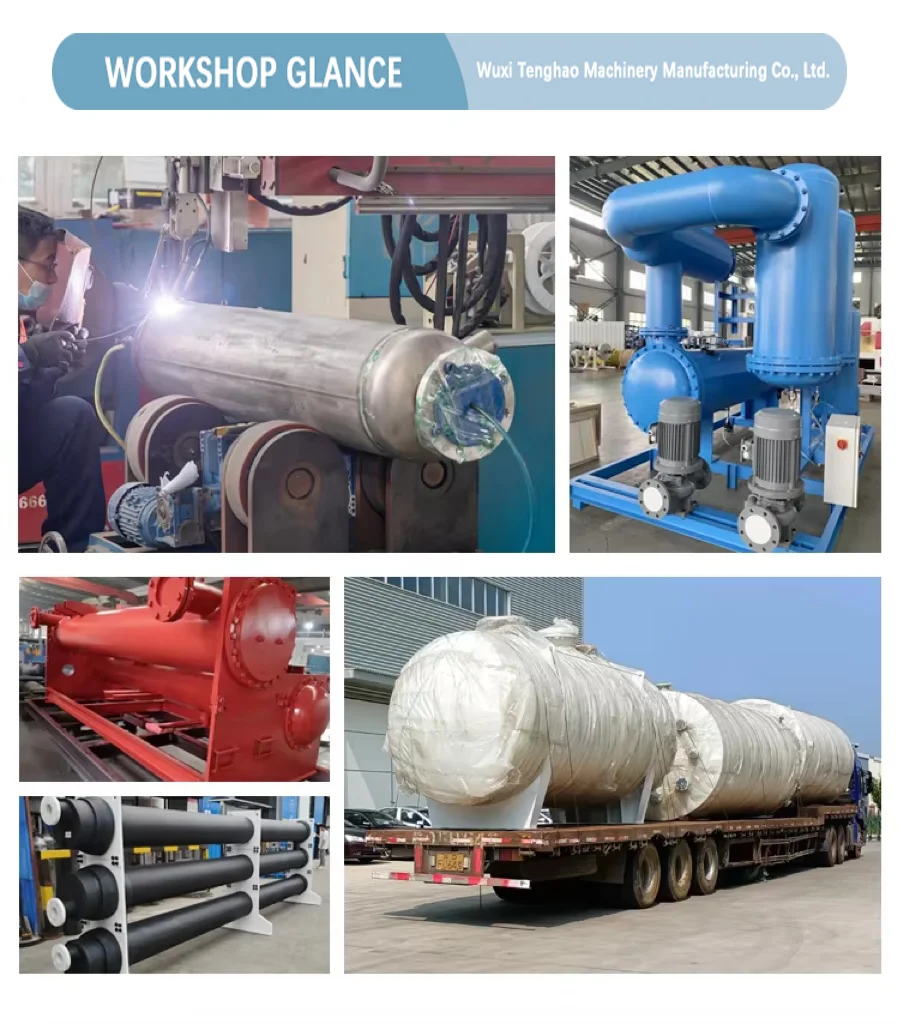

Company Profile

Product packaging

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.