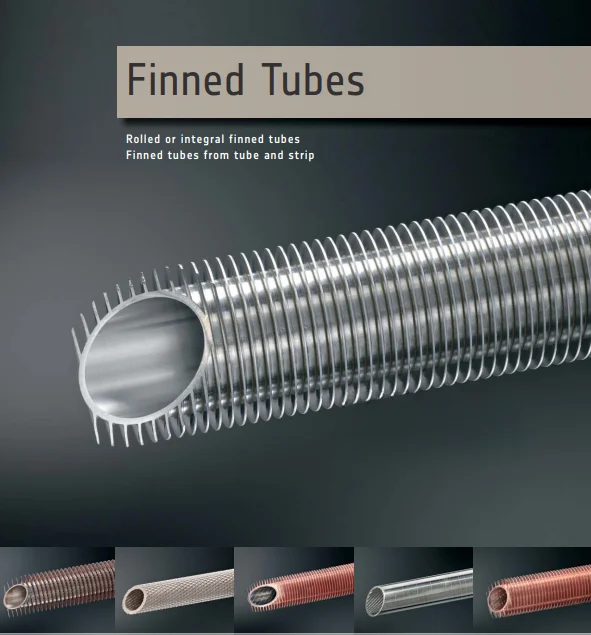

A high-frequency laser finned tube is a precision-engineered heat exchange component designed for extreme thermal management

scenarios. By integrating laser-welded fins with a high-conductivity base tube, it delivers superior heat dissipation for

high-power equipment, ensuring stability and energy efficiency.

Products Description

High-frequency laser finned tube

Key Features & Advantages

✅ Ultra-High Heat Transfer Efficiency

* Laser-welded fins (0.2~0.5mm thickness) achieve 95%+ thermal conductivity vs. traditional bonded fins.

* Optimized fin density (8~16 FPI*) maximizes surface area for rapid cooling.

✅ Robust Durability

* Material options: Copper/Aluminum base tube + stainless steel/Al fins (anti-corrosion, 500°C resistant).

* Vibration-resistant laser welding prevents fin loosening under high airflow/pressure.

✅ Customizable Designs

* Tube diameters: 8mm~50mm | Fin heights: 5mm~15mm (OEM specifications supported).

* Compatible with water, oil, or refrigerant cooling systems.

* Laser-welded fins (0.2~0.5mm thickness) achieve 95%+ thermal conductivity vs. traditional bonded fins.

* Optimized fin density (8~16 FPI*) maximizes surface area for rapid cooling.

✅ Robust Durability

* Material options: Copper/Aluminum base tube + stainless steel/Al fins (anti-corrosion, 500°C resistant).

* Vibration-resistant laser welding prevents fin loosening under high airflow/pressure.

✅ Customizable Designs

* Tube diameters: 8mm~50mm | Fin heights: 5mm~15mm (OEM specifications supported).

* Compatible with water, oil, or refrigerant cooling systems.

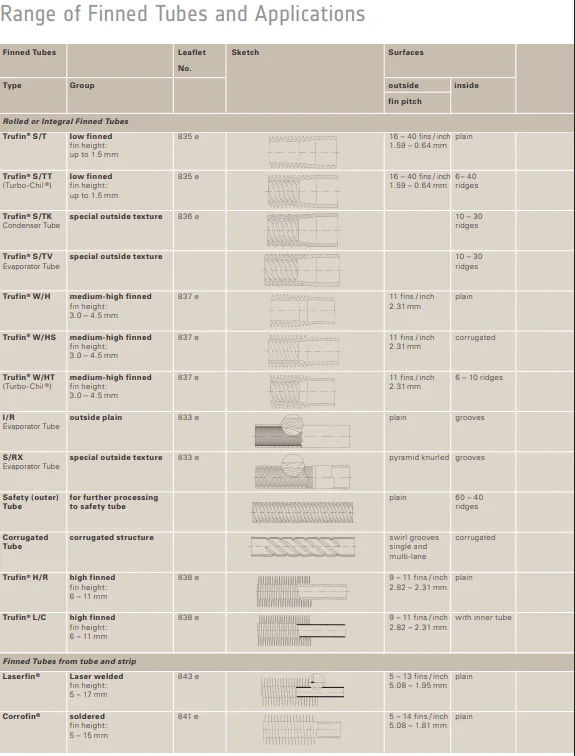

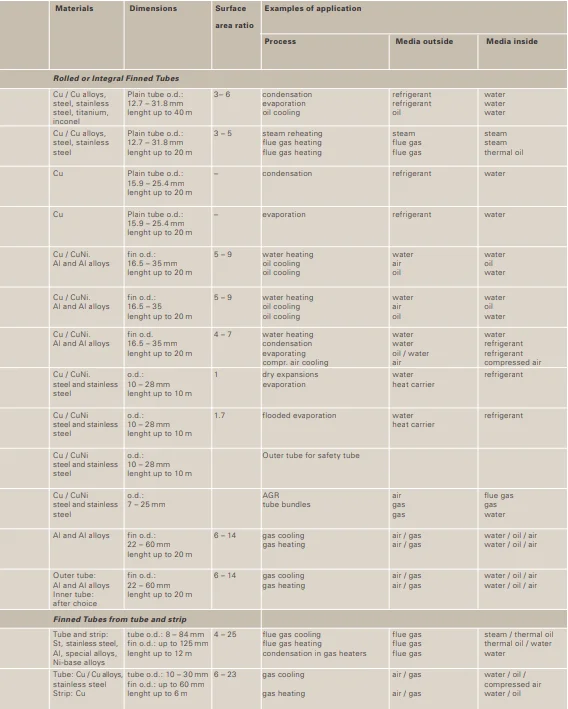

Technical Specifications

ParameterSpecificationBase Tube MaterialCopper, Aluminum, Stainless SteelFin MaterialAluminum/Stainless SteelOperating Pressure

≤3.0MPaTemperature Range-50°C ~ +300°CWelding MethodHigh-Frequency Laser Precision Welding

≤3.0MPaTemperature Range-50°C ~ +300°CWelding MethodHigh-Frequency Laser Precision Welding

Typical Applications

\uD83D\uDD39 Laser Equipment: Cooling modules for fiber lasers/CO₂ lasers in cutting/welding.

\uD83D\uDD39 Power Electronics: Heat sinks for IGBT modules, EV battery cooling.

\uD83D\uDD39 HVAC & Refrigeration: Condenser/evaporator tubes for industrial chillers.

\uD83D\uDD39 Energy Recovery: Waste heat exchangers in turbines/boilers.

\uD83D\uDD39 Power Electronics: Heat sinks for IGBT modules, EV battery cooling.

\uD83D\uDD39 HVAC & Refrigeration: Condenser/evaporator tubes for industrial chillers.

\uD83D\uDD39 Energy Recovery: Waste heat exchangers in turbines/boilers.

Typical application fields

Laser equipment cooling High-power lasers: Resonant cavity cooling for fiber laser cutting machines and CO₂ laser welding machines. 3D printing: Heat exchange module for metal powder melting forming equipment. 2. Heat dissipation for power electronics IGBT module: Heat dissipation for power devices in new energy vehicles and photovoltaic inverters. Battery thermal management: The heat exchange core in the liquid cooling system of lithium battery packs. 3. Industrial refrigeration and energy recovery HVAC system: Commercial air conditioning condenser/evaporator. Waste heat utilization: Heat exchange tubes for gas turbine flue gas heat recovery.

Core features and advantages

1. High-efficiency heat conduction performance Laser welded fins: The fins (0.2~0.5mm thin type) are welded to the base tube (copper/aluminum/stainless steel) through high-frequency laser welding, with extremely low contact thermal resistance. The heat conduction efficiency is increased by more than 30% compared with the traditional tube expansion process. Optimize the fin density: 8 to 16 FPI (number of fins per inch), increase the heat dissipation area, and adapt to different flow rate requirements. 2. Excellent durability Anti-corrosion materials: Copper tubes + stainless steel fins or full aluminum alloy materials are available. Resistant to acid and alkali, anti-oxidation, suitable for humid or corrosive environments. Anti-vibration design: The laser welded structure avoids the fin detachment problem of traditional brazing and is suitable for high wind speed or mechanical vibration scenarios. 3. Flexible customization Size range: Base tube diameter 8mm - 50mm | Fin height 5mm - 15mm (non-standard design supported). Medium compatibility: Suitable for various cooling working media such as water, oil, and refrigerants (such as R134a).

Video presentation

Manufacturing Technique

Recommend Products

Company Profile

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.