An Air Boiler Steam Heat Exchanger is a high-efficiency thermal transfer device designed to recover waste heat from steam systems

and transfer it to air streams. It is widely used in industrial heating, drying, and energy recovery applications.

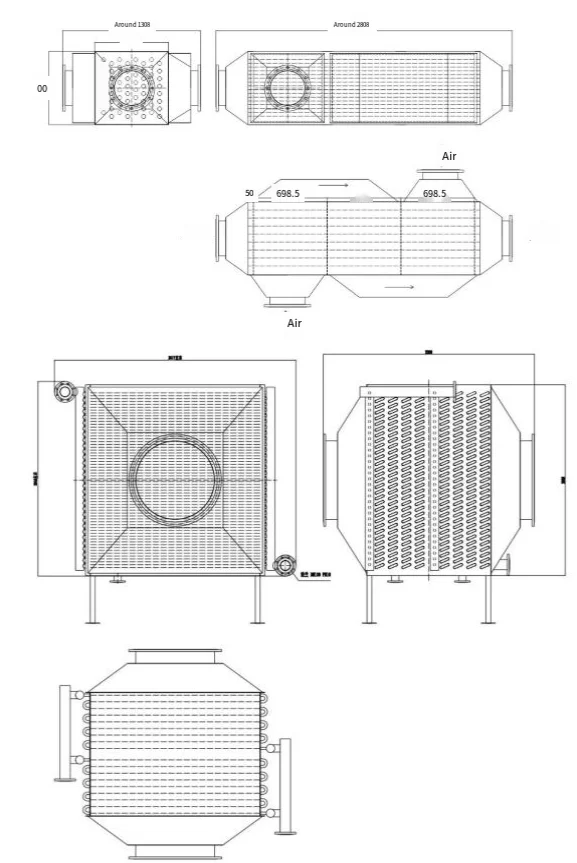

Products Description

Air boiler steam heat exchanger

Key Features

✔ High Thermal Efficiency (80-95%) – Maximizes heat recovery from steam.

✔ Compact & Modular Design – Saves space compared to shell-and-tube exchangers.

✔ Corrosion-Resistant Materials – Stainless steel, titanium, or coated steel options.

✔ Low Maintenance – Easy-to-clean plate or finned-tube configurations.

✔ Smart Control Integration – Optional IoT monitoring for real-time optimization.

✔ Compact & Modular Design – Saves space compared to shell-and-tube exchangers.

✔ Corrosion-Resistant Materials – Stainless steel, titanium, or coated steel options.

✔ Low Maintenance – Easy-to-clean plate or finned-tube configurations.

✔ Smart Control Integration – Optional IoT monitoring for real-time optimization.

Applications

① Industrial Heating & Drying

* Food Processing – Steam-to-air heat for drying ovens, sterilizers.

* Textile Industry – Humidity control in fabric drying chambers.

* Paper Manufacturing – Hot air supply for paper coating machines.

② Energy Recovery Systems

* Boiler Flue Gas Heat Recovery – Preheats combustion air (saves 10-20% fuel).

* Waste Heat to Steam – Converts exhaust heat into usable steam.

③ HVAC & District Heating

* Commercial Buildings – Steam-based air heating for large facilities.

* Greenhouses – Maintains optimal temperature using recovered steam heat.

④ Specialized Applications

* Marine & Offshore – Compact steam-air exchangers for shipboard heating.

* Chemical Plants – Safe heat transfer for corrosive environments.

* Food Processing – Steam-to-air heat for drying ovens, sterilizers.

* Textile Industry – Humidity control in fabric drying chambers.

* Paper Manufacturing – Hot air supply for paper coating machines.

② Energy Recovery Systems

* Boiler Flue Gas Heat Recovery – Preheats combustion air (saves 10-20% fuel).

* Waste Heat to Steam – Converts exhaust heat into usable steam.

③ HVAC & District Heating

* Commercial Buildings – Steam-based air heating for large facilities.

* Greenhouses – Maintains optimal temperature using recovered steam heat.

④ Specialized Applications

* Marine & Offshore – Compact steam-air exchangers for shipboard heating.

* Chemical Plants – Safe heat transfer for corrosive environments.

Technical Parameters

① Performance Specifications

ParameterRangeHeat Transfer Area5–500 m² (customizable)Max Steam Pressure0.5–4.0 MPa (72–580 psi)Steam Temperature100–500°C

(212–932°F)Airflow Capacity500–50,000 m³/hThermal Efficiency80–95%Pressure Drop (Air)50–300 Pa (0.2–1.2 inH₂O)

② Material Options

ComponentMaterial ChoicesBest ForHeat Plates/Tubes304/316L Stainless Steel, TitaniumCorrosive/High-Temp SteamAirside FinsAluminum,

Corten SteelDusty/Acidic AirflowsGaskets/SealsEPDM, PTFE, GraphiteSteam Leak PreventionFrame/CasingCarbon Steel (Painted), SS304

Structural Durability

③ Customization Options

* Explosion-Proof Design (ATEX/IECEx certified)

* Self-Cleaning Mechanisms (For dusty air applications)

* Hybrid MVR (Mechanical Vapor Recompression) Integration

ParameterRangeHeat Transfer Area5–500 m² (customizable)Max Steam Pressure0.5–4.0 MPa (72–580 psi)Steam Temperature100–500°C

(212–932°F)Airflow Capacity500–50,000 m³/hThermal Efficiency80–95%Pressure Drop (Air)50–300 Pa (0.2–1.2 inH₂O)

② Material Options

ComponentMaterial ChoicesBest ForHeat Plates/Tubes304/316L Stainless Steel, TitaniumCorrosive/High-Temp SteamAirside FinsAluminum,

Corten SteelDusty/Acidic AirflowsGaskets/SealsEPDM, PTFE, GraphiteSteam Leak PreventionFrame/CasingCarbon Steel (Painted), SS304

Structural Durability

③ Customization Options

* Explosion-Proof Design (ATEX/IECEx certified)

* Self-Cleaning Mechanisms (For dusty air applications)

* Hybrid MVR (Mechanical Vapor Recompression) Integration

Video presentation

Details Images

Why Choose Our Air Boiler Steam Heat Exchanger?

✅ Higher Efficiency – Patented turbulator design enhances heat transfer.

✅ Longer Lifespan – Anti-corrosion coatings & robust welding.

✅ Global Compliance – ASME, PED, CE, and GB standards.

✅ Turnkey Solutions – From thermal calculations to installation.

✅ Longer Lifespan – Anti-corrosion coatings & robust welding.

✅ Global Compliance – ASME, PED, CE, and GB standards.

✅ Turnkey Solutions – From thermal calculations to installation.

The principle and function of waste heat recovery equipment

The waste gas recovery device utilizes thermodynamic principles to convert the waste heat generated in industrial production processes into usable thermal energy. The energy saver of the waste heat boiler absorbs the waste heat generated in the industrial production process, converts it into steam or thermal energy, and then transforms it into useful work such as mechanical energy or electrical energy. The waste heat recovery device is mainly composed of a heat exchanger, condenser, evaporator, compressor and other parts. The function of the waste heat recovery device is to recover the waste heat generated in the industrial production process and convert it into thermal energy. It can effectively reduce energy consumption, decrease environmental pollution and improve energy utilization efficiency. In industrial production, waste heat is a kind of wasted energy. However, waste heat recovery devices can convert it into usable thermal energy, thereby reducing energy consumption and minimizing environmental pollution.

Application fields of boiler waste heat recovery and utilization engineering

The application of waste heat recovery heat exchangers is very extensive, mainly used in sludge drying, waste heat recovery and utilization, waste battery treatment, garbage incineration treatment, domestic hot water, industrial electroplating heating, industrial PCB circuit board electroplating heating, medical and biotechnology heating, furniture and furniture drying, Chinese medicinal materials drying, agricultural product drying, etc. In the power industry, heat recovery systems can be applied in boiler economizers to convert the heat in the exhaust gas discharged from boilers into steam, thereby reducing energy consumption. In the steel industry, it can be applied to the recovery and utilization of waste heat from waste gas, converting the heat in the waste gas produced during the steel production process into steam, thereby reducing energy consumption. In the chemical industry, it can be applied in the waste heat recovery device of boilers to convert the heat in the exhaust gas discharged from boilers into steam, thereby reducing energy consumption. In the papermaking industry, it can be applied to the renovation of the heating system at the upper head of the paper machine, converting the heat in the discharged exhaust gas into steam, thereby reducing energy consumption.

Recommend Products

Company Profile

Contact information

FAQ

Q:Worry about your money?

A: Trade Assurance can protect your money. (more information, pls contact me)

Q: Are you trading company or manufacturer ?

A: We are factory.specilizing in heat exchanger for over 10 years.

Q:Are your products customized?

A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the

newproducts according to your requirements or drawings.

Q: How long is your delivery time?

A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: WHY CHOOSE US?

A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are

committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.

A: Trade Assurance can protect your money. (more information, pls contact me)

Q: Are you trading company or manufacturer ?

A: We are factory.specilizing in heat exchanger for over 10 years.

Q:Are your products customized?

A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the

newproducts according to your requirements or drawings.

Q: How long is your delivery time?

A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: WHY CHOOSE US?

A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are

committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.