Our Plate Heat Exchangers are the ultimate solution for pasteurization processes in milk and beer factories, designed to meet the

highest standards of hygiene, efficiency, and reliability.

Products Description

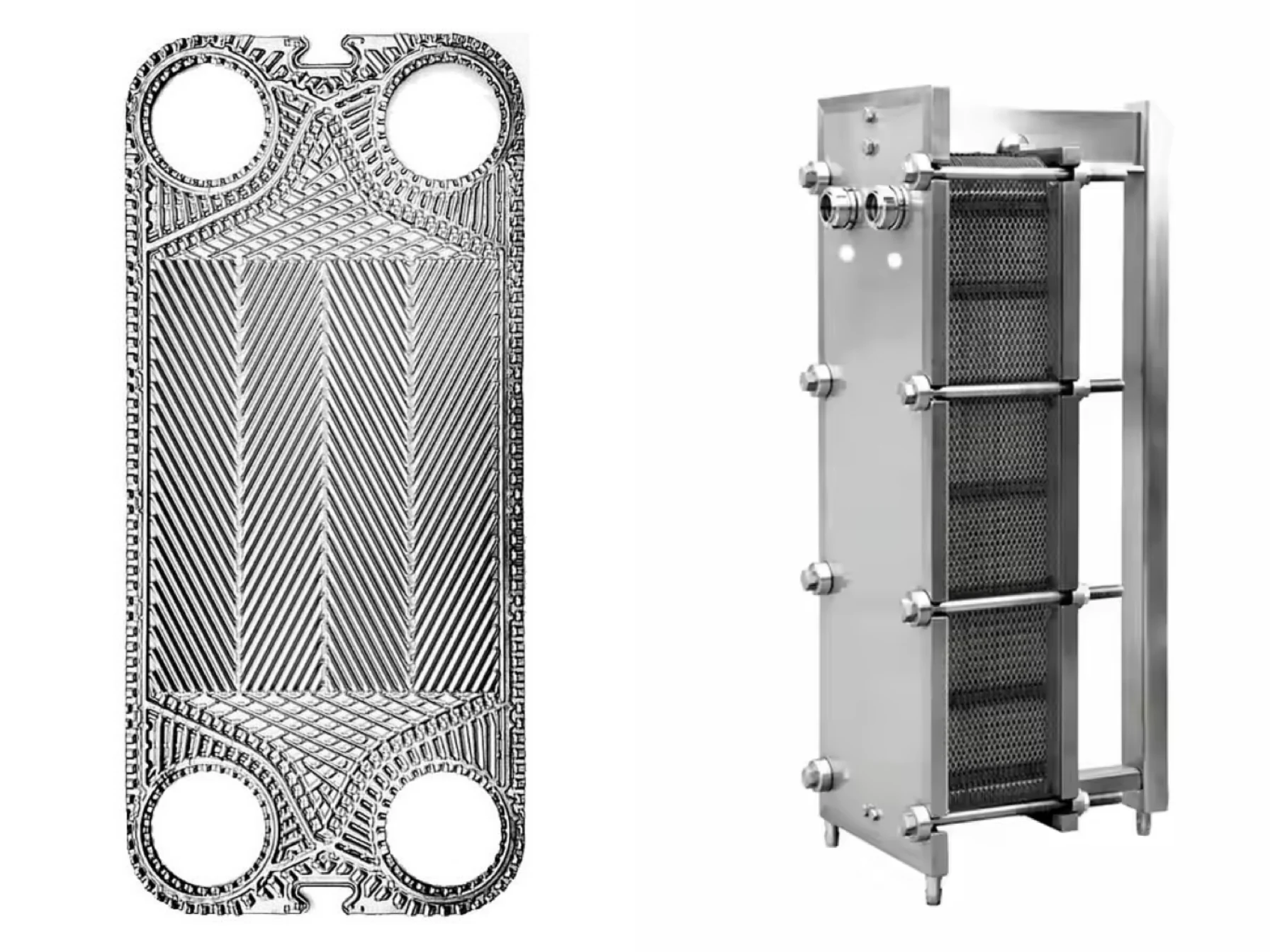

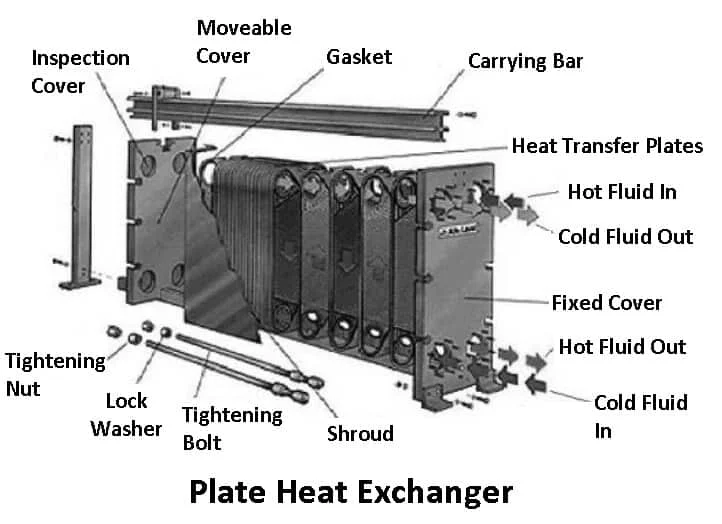

Plate heat exchanger

Unrivaled Hygiene Standards

Crafted from premium 316L stainless steel, our heat exchangers comply with stringent international regulations, including FDA,

NSF, and EC 1935/2004. The electropolished surface (Ra ≤0.8μm) minimizes bacterial adhesion, while food-grade EPDM or silicone

gaskets prevent contamination. The design is fully compatible with Clean-in-Place (CIP) systems, allowing for automatic

sanitization with caustic solutions, ensuring maximum product purity and safety.

NSF, and EC 1935/2004. The electropolished surface (Ra ≤0.8μm) minimizes bacterial adhesion, while food-grade EPDM or silicone

gaskets prevent contamination. The design is fully compatible with Clean-in-Place (CIP) systems, allowing for automatic

sanitization with caustic solutions, ensuring maximum product purity and safety.

Exceptional Heat Transfer Efficiency

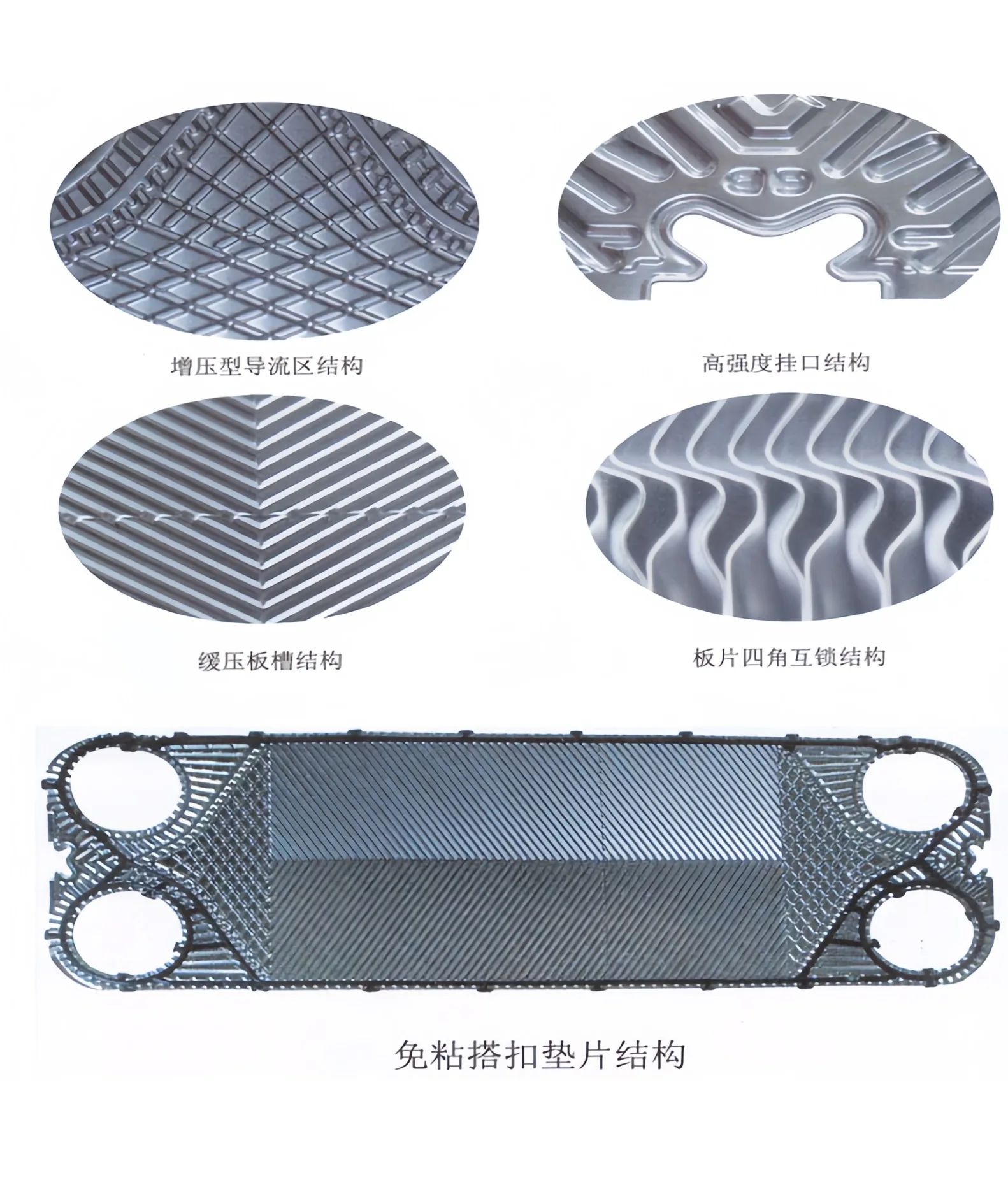

Featuring a unique chevron plate design, our heat exchangers increase turbulence and heat transfer area by 30 - 50%, enabling

rapid heating and cooling within 30 - 60 seconds. The counterflow configuration maximizes the temperature difference between

media, reducing energy consumption by 20 - 30% compared to traditional shell-and-tube exchangers. With a heat transfer coefficient

(U-value) of up to 800 - 1,200 W/(m²·K), our exchangers ensure precise temperature control within ±0.5°C, meeting the strict

time-temperature requirements of pasteurization processes (e.g., 72°C for 15 seconds or 63°C for 30 minutes).

rapid heating and cooling within 30 - 60 seconds. The counterflow configuration maximizes the temperature difference between

media, reducing energy consumption by 20 - 30% compared to traditional shell-and-tube exchangers. With a heat transfer coefficient

(U-value) of up to 800 - 1,200 W/(m²·K), our exchangers ensure precise temperature control within ±0.5°C, meeting the strict

time-temperature requirements of pasteurization processes (e.g., 72°C for 15 seconds or 63°C for 30 minutes).

Versatile Applications

* Dairy Industry: Ideal for pasteurizing fresh cow’s milk, goat’s milk, plant-based milk, and processing dairy products like

yogurt, cream, and cheese. Also suitable for sanitizing whey and producing specialty dairy items.

* Brewing Industry: Perfect for pasteurizing bottled, canned, or kegged beer to extend shelf life without altering flavor.

Capable of handling small-scale craft brewing as well as large commercial operations, and can be used for heating brewing water

and cooling wort.

yogurt, cream, and cheese. Also suitable for sanitizing whey and producing specialty dairy items.

* Brewing Industry: Perfect for pasteurizing bottled, canned, or kegged beer to extend shelf life without altering flavor.

Capable of handling small-scale craft brewing as well as large commercial operations, and can be used for heating brewing water

and cooling wort.

Video presentation

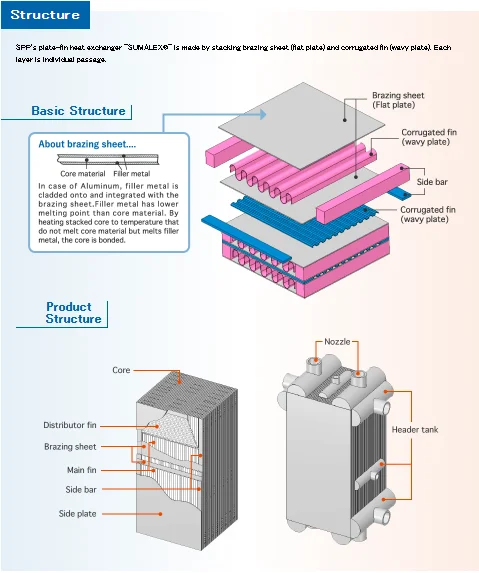

Manufacturing Technique

Durability and Low Maintenance

Durability and Low Maintenance

Built to withstand high pressures (tested up to 2.5 MPa) and extreme temperatures, our heat exchangers are engineered for

long-term, reliable operation. The robust construction, combined with a leak detection design and built-in drainage channels,

prevents cross-contamination and reduces the risk of maintenance issues, with service intervals of over 5,000 hours.

Built to withstand high pressures (tested up to 2.5 MPa) and extreme temperatures, our heat exchangers are engineered for

long-term, reliable operation. The robust construction, combined with a leak detection design and built-in drainage channels,

prevents cross-contamination and reduces the risk of maintenance issues, with service intervals of over 5,000 hours.

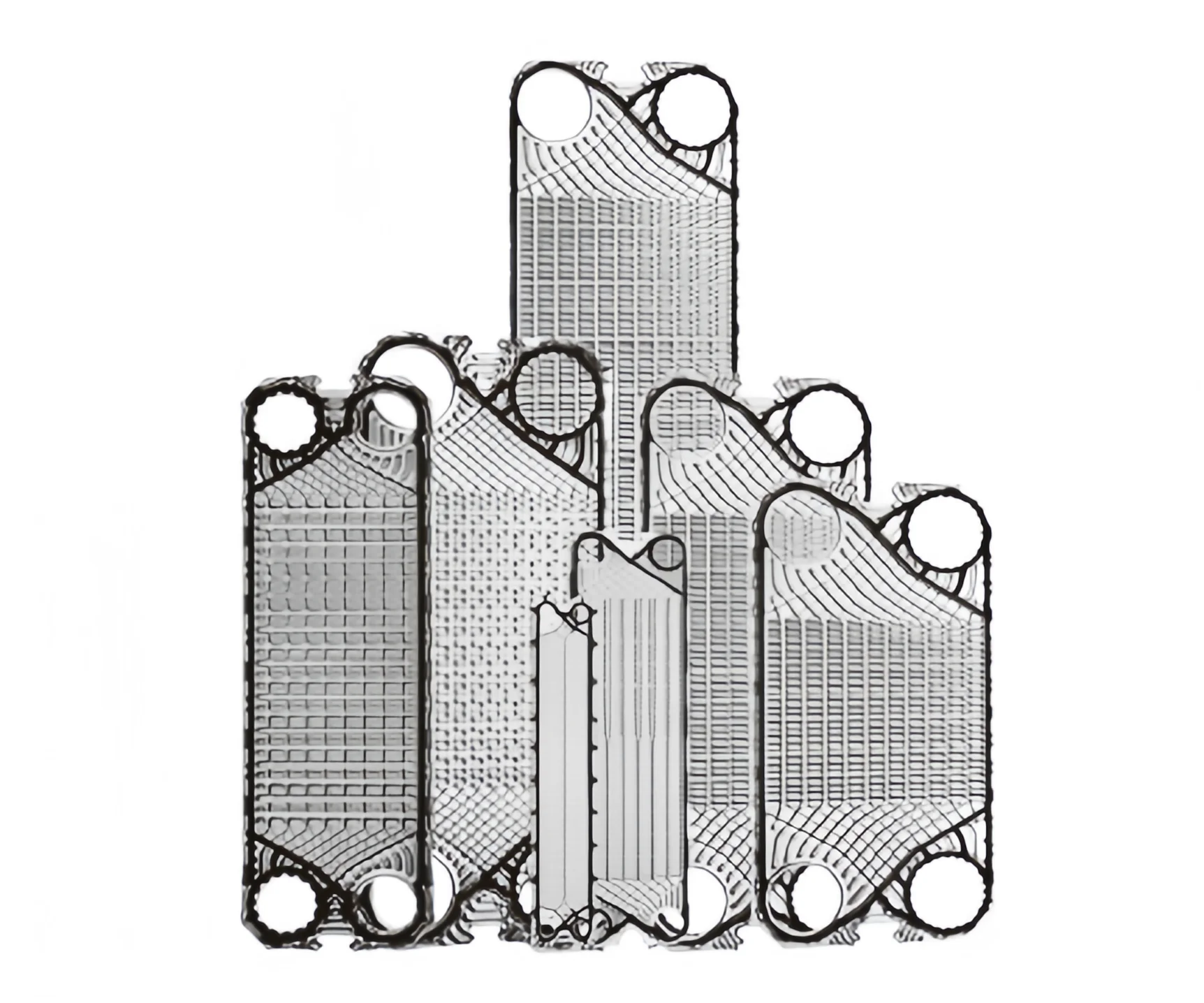

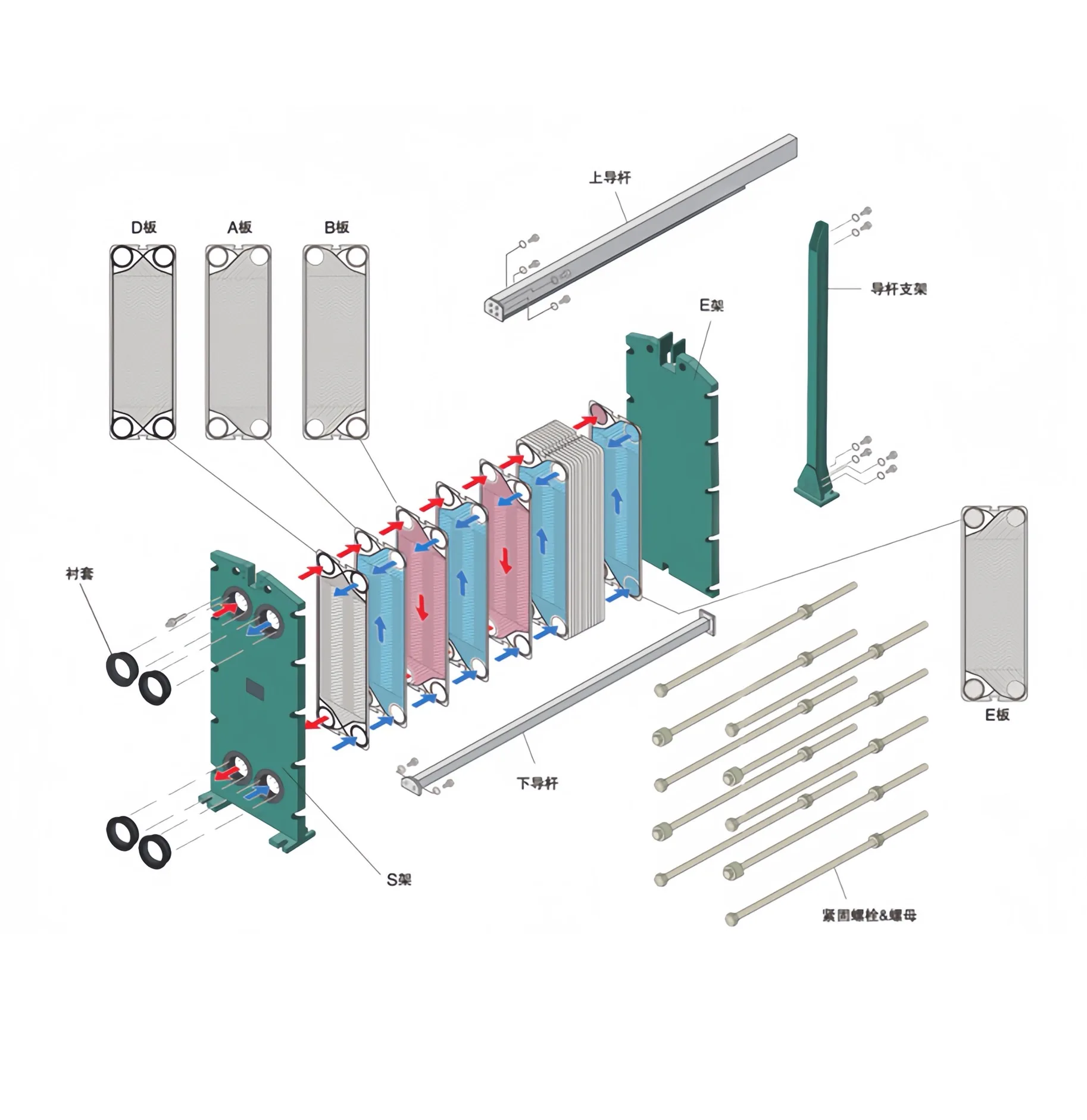

Modular and Scalable Design

Our plate heat exchangers feature a compact and modular structure, with a footprint 50 - 70% smaller than conventional heat

exchangers, making them ideal for facilities with limited space. The scalable plate pack design allows you to easily add or remove

plates to adjust the heat duty, ranging from 10 - 500 kW, to accommodate varying production volumes, from 500L/h to 50,000L/h

pasteurization lines.

exchangers, making them ideal for facilities with limited space. The scalable plate pack design allows you to easily add or remove

plates to adjust the heat duty, ranging from 10 - 500 kW, to accommodate varying production volumes, from 500L/h to 50,000L/h

pasteurization lines.

Energy Recovery and Sustainability

Equipped with an advanced heat regeneration system, our heat exchangers can reuse 70 - 90% of the thermal energy from pasteurized

products to preheat incoming raw materials, significantly cutting down on steam consumption and energy costs. The compact design

also reduces material usage, contributing to a lower carbon footprint and aligning with sustainable manufacturing practices.

In summary, our Plate Heat Exchangers offer an unbeatable combination of hygiene, efficiency, versatility, and durability, making

them the preferred choice for pasteurization in milk and beer factories worldwide. Contact us today to learn more about how our

products can enhance your production processes.

products to preheat incoming raw materials, significantly cutting down on steam consumption and energy costs. The compact design

also reduces material usage, contributing to a lower carbon footprint and aligning with sustainable manufacturing practices.

In summary, our Plate Heat Exchangers offer an unbeatable combination of hygiene, efficiency, versatility, and durability, making

them the preferred choice for pasteurization in milk and beer factories worldwide. Contact us today to learn more about how our

products can enhance your production processes.

Company Profile

Product packaging

Recommend Products

Contact information

FAQ

Q:Worry about your money? A: Trade Assurance can protect your money. (more information, pls contact me) Q: Are you trading company or manufacturer ? A: We are factory.specilizing in heat exchanger for over 10 years. Q:Are your products customized? A:Yes,the products in the website are only the common type or the previous types from other customers,we can supply the newproducts according to your requirements or drawings. Q: How long is your delivery time? A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: WHY CHOOSE US? A:We have strong technical force, with more than 10 years of experience in research and development of heat exchangers,We are committed to providing our customers with the most suitable heat transfer equipment and efficient energy saving needs.