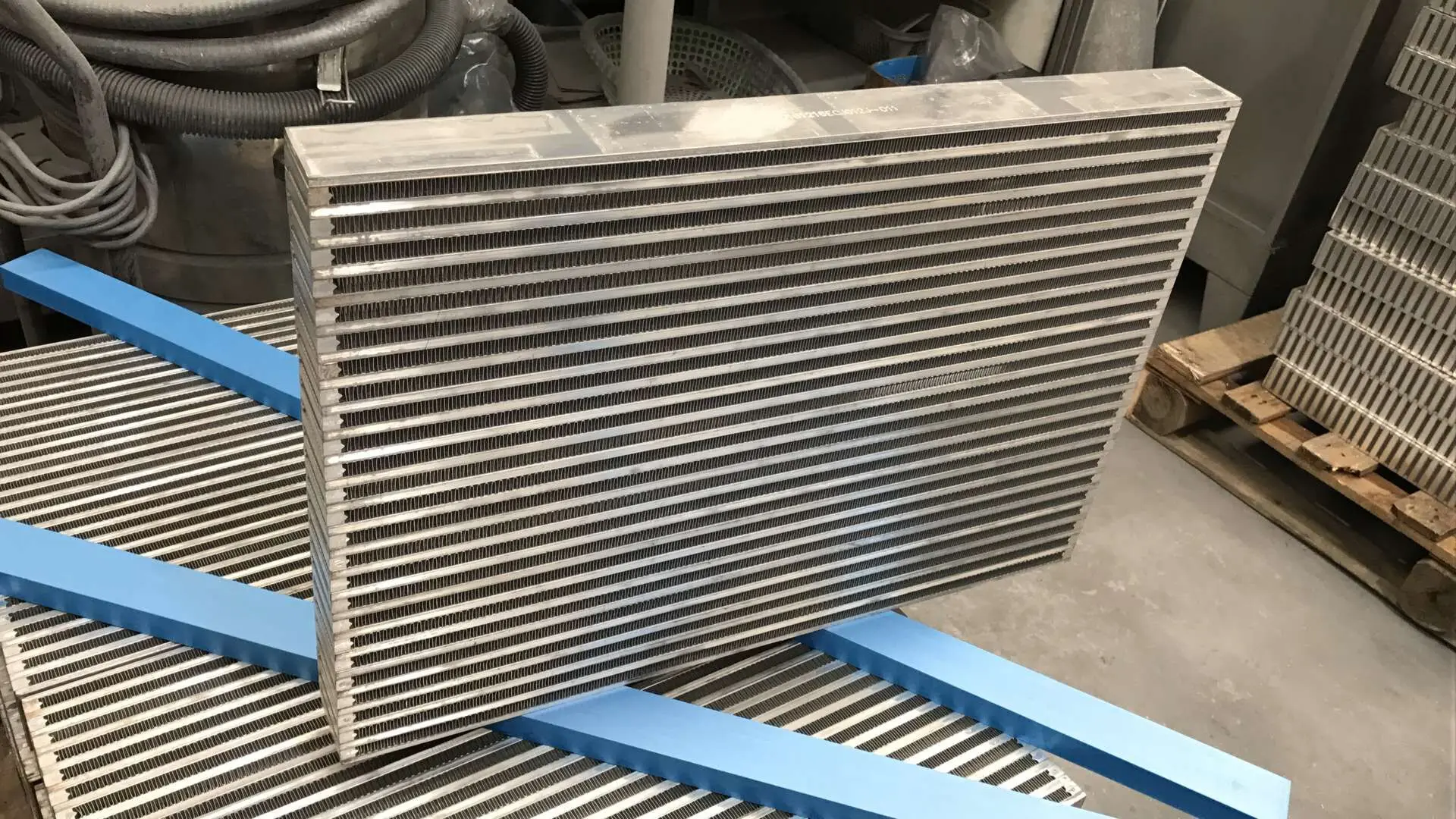

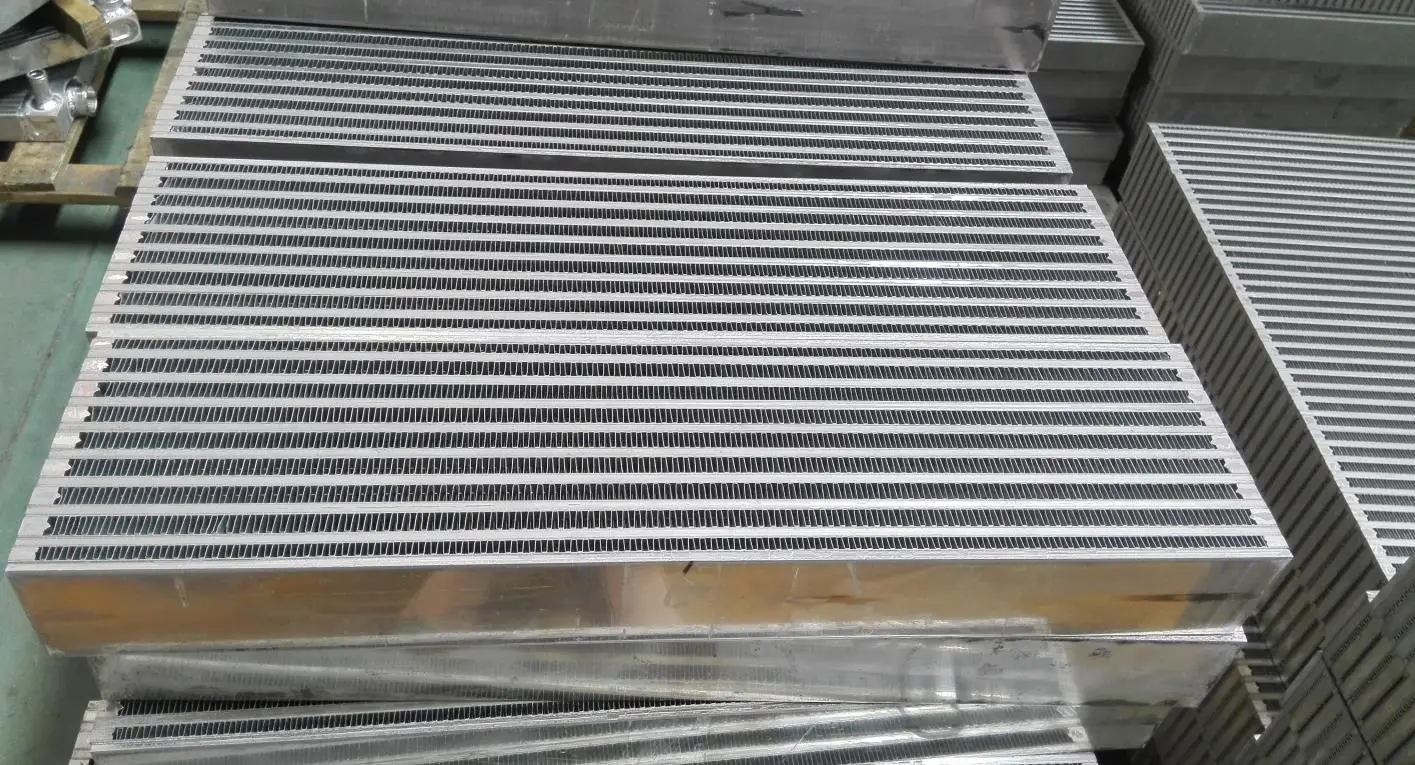

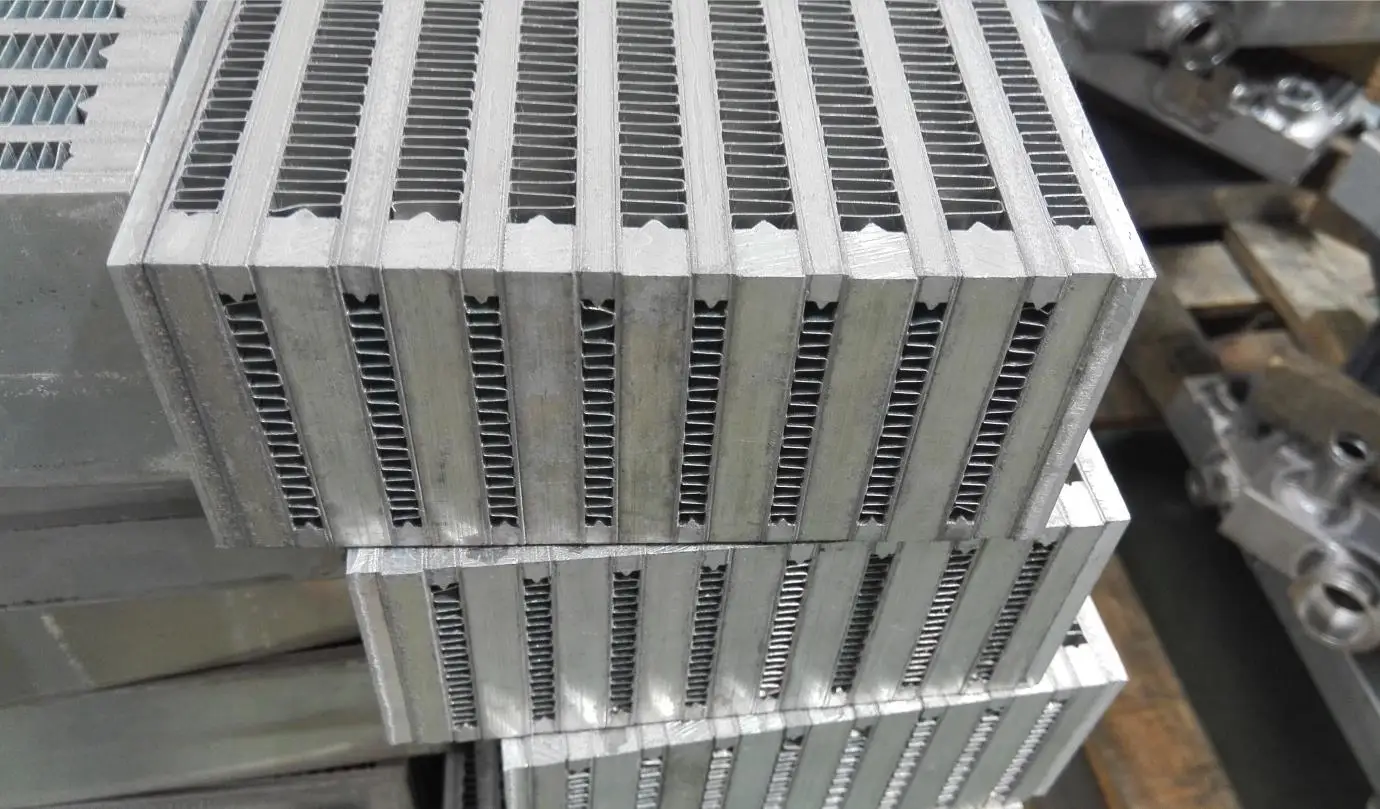

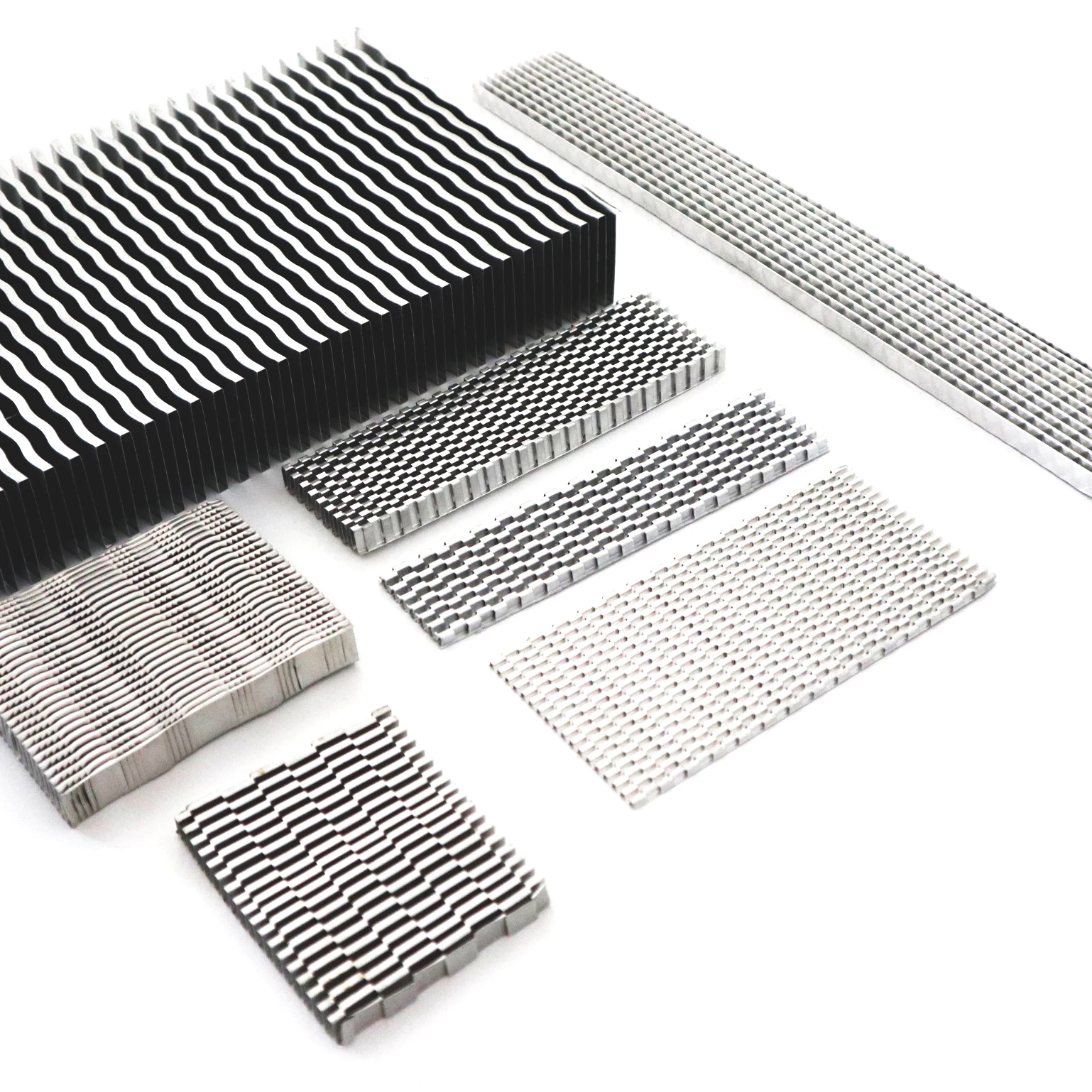

Heat exchanger core, made from high quality aluminum alloy, provides outstanding heat exchange capabilities, largely improving thermal performance.热交换器芯采用优质铝合金制造,具有出色的换热能力,大大提高了热性能。

New type of both internal and external cores features a completely new take on core's fins arrangement, resulting in improved heat exchange and air flow. Alternately placed heat exchanger fins significantly improve cooling capabilities.新型内外芯采用了全新的芯片布置,从而改善了热交换和空气流动。交替放置的热交换器翅片显著提高冷却能力。

|

NO. 否。

|

ITEM DESCRIPTION 项目描述

|

CONTENT 内容

|

|

|

||

|

1

|

Product name 产品名称

|

hydraulic oil cooler core液压油冷却器芯

|

|

|

||

|

2

|

Pettern

|

AH1012T-CA

|

|

|

||

|

3

|

Rate of flow 流量

|

100L/min 100升/分钟

|

|

|

||

|

4

|

Working pressure 工作压力

|

≤2MPa ≤2 mpa

|

|

|

||

|

5

|

6Fan power 6风机功率

|

60W 60 w

|

|

|

||

|

6

|

Fan voltage 风扇电压

|

AC220V/380V DC12V/24V AC220V / 380 v 12 v / 24 v

|

|

|

||

|

7

|

Exterior cooling area 外部冷却面积

|

2.6m²

|

|

|

||

|

8

|

The warranty 保修

|

12 months 12个月

|

|

|

||

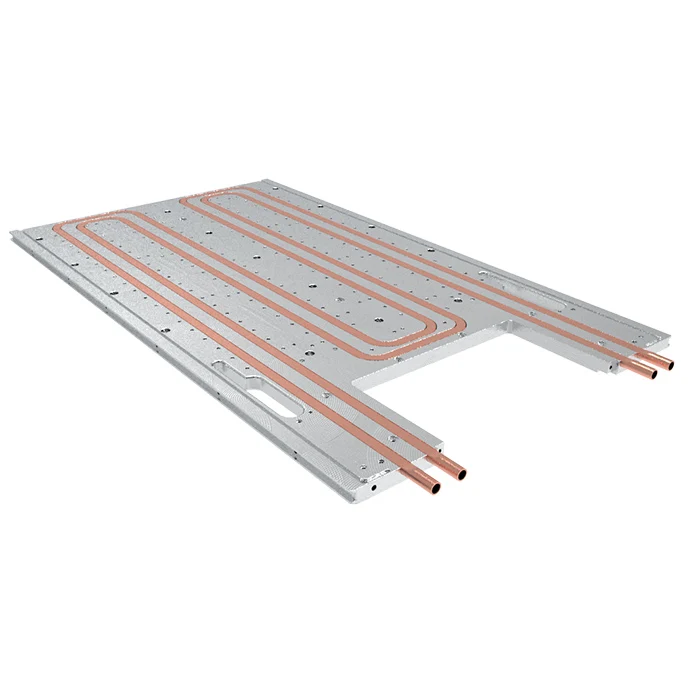

Liquid cooling plate 液冷板

Heat exchanger parts aluminum fin换热器部件铝制翅片

Nanjing Metalli-your ideal partner for thermal management and metal fabrication solutions南京金属-热管理和金属加工解决方案的理想合作伙伴

✅ Since 2008, Nanjing Metalli has been focusing on thermal management field. Our capabilities cover a wide range that provide you one-stop solution quicker and easier. Our main capabilities include:✅自2008年以来,南京金属一直专注于热管理领域。我们的能力涵盖范围广泛,为您提供一站式解决方案更快,更容易。我们的主要能力包括:

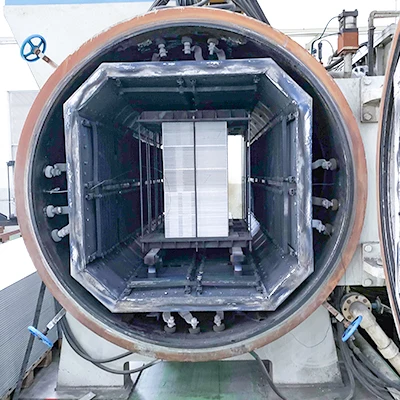

◇ Vacuum Brazing and Controlled Atmosphere Brazing真空钎焊和可控气氛钎焊

◇ CNC machining 数控加工

◇ Welding 焊接

◇ Aluminum extrusion 铝挤压

◇ Aluminum die casting 铝压铸件

◇ Sheet metal fabrication covering laser cutting, stamping, drawing and bending钣金加工,包括激光切割,冲压,拉伸和弯曲

◇ Surface coating 表面涂层

✅We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.✅我们强调原型过程。我们利用我们在流体动力学、热性能和材料兼容性方面的丰富经验来优化您的设计。为了进行高级热分析,我们的工程师使用CFD、6 Sigma等仿真软件。除了提供专业的热能和机械设计工程外,我们还确保您的产品符合DFM概念,以便您的产品可以按照您的确切规格建造,并满足您的交货时间表。

✅ We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss✅我们从制造的角度来看待质量问题。更注重监控和最小化过程变量,以保持稳定的质量水平。交付的产品经过100%的检验或测试。减少对质量风险和损失的担忧

✅ Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.✅我们的精益生产和持续改进计划旨在消除所有不能增加价值的浪费。我们的客户不需要为废物付费。成本将越来越有竞争力,这有助于你的业务发展和成功。

Vacuum Brazing Furnace 真空钎焊炉

CNC Machine 数控机床

100% tested or Inspected 100%测试或检验