Understanding Finned Tube Heat Exchanger Technology

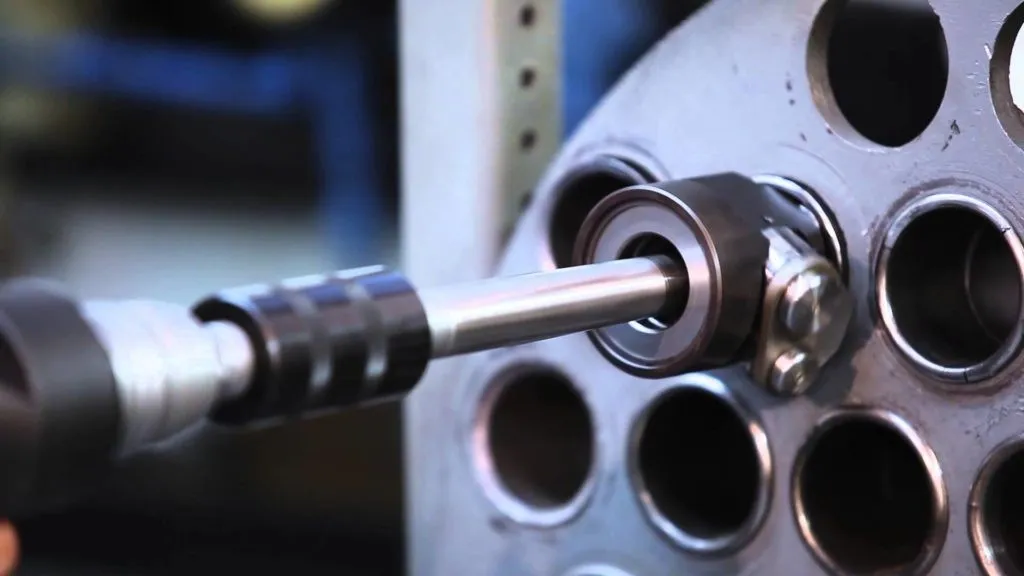

Finned tube heat exchangers are a cornerstone in the oil and gas industry, providing efficient solutions for heat transfer. Built with robust technology, these exchangers serve as critical components in oil and gas thermal equipment. The integration of finned tube technology enhances the overall thermal management system, ensuring optimal performance in various demanding conditions. When it comes to industrial finned tube exchangers, their design caters to the unique needs of oil and gas processing equipment, ensuring that operations run smoothly and efficiently.

Advantages of Titanium Plate Gasket Exchanger

Introducing the Titanium Plate Gasket Exchanger: an innovation in fluid thermal management. Crafted with high hygiene standards in mind, it boasts robust construction using pure titanium (Gr.1/2) or titanium-palladium alloy (Gr.7/11) for harsh environments. Each exchanger embraces a polished corrugated plate design, leveraging titanium's thermal conductivity to ensure heat exchange efficiency, suitable for high-temperature and pressure scenarios. The modularity of this design guarantees less downtime, making it indispensable in sectors such as chemical, marine, and pharmaceuticals. It is tailored to combat corrosiveness, with plates pairing fluororubber (FKM) or PTFE gaskets for enduring performance.

The Role of Heat Exchangers in Oil and Gas Industry

Heat exchangers play a pivotal role in the oil and gas industry by facilitating critical thermal management processes. Utilizing welded finned tube heat exchangers improves the ability of the industry to manage heat transfer solutions effectively. The adaptability and precision-engineered design help in cooling aggressive mediums such as sulfuric acid, often encountered in petrochemical plants. With certification to ASME, PED, and CE standards, the integration of these exchangers ensures reliability and enhancement of processes, making them invaluable for various applications, including geothermal power stations and seawater desalination.