Use fin tube heat exchangers to completely change industrial heat exchange

In the ever-evolving landscape of thermal management systems, the importance of cutting-edge heat exchangers cannot be exaggerated. Fin tube heat exchangers are respected for their efficiency and versatility, representing the pinnacle of innovation in the region. This article delves into the advanced functions and applications of fin tube heat exchangers, emphasizing its essential role in modern industry.

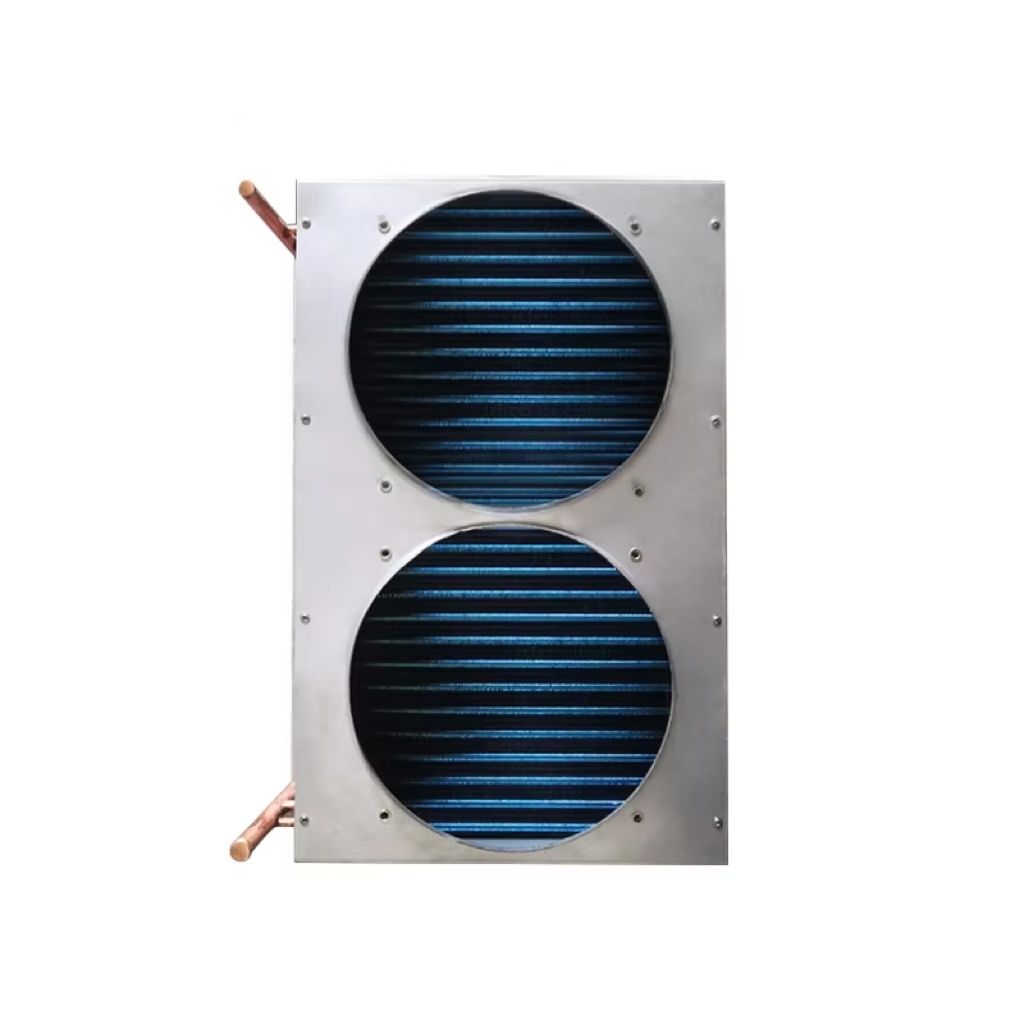

The most advanced heat exchanger module

Please allow me to introduce an impeccable product that proves the glory of modern engineering: the most advanced aluminum heat exchanger module, a microcosm of the latest advancements in industrial heat exchange technology. The assembly is carefully crafted from premium aluminum and is praised for its lightweight but sturdy nature. These properties allow for maximum efficiency and durability even in the most demanding environments.

The aluminum heat exchanger is characterized by its smooth design, which includes a series of tightly arranged horizontal fins. These fins are critical in promoting optimal airflow and heat dissipation, thereby significantly improving the performance of any heating or cooling system integrated with them. The module is designed with a precise design, combining a framework designed to be easy to install and integrate on a variety of industrial settings and is used with contour fins to minimize air drag while enhancing heat transfer. This modularity ensures its adaptability in a wide range of applications, from automobiles to aviation, heavy machinery to the energy sector.

Environmental Innovation

Investing in this cutting-edge heat exchanger means investing in performance optimization and sustainability. Designed with an environmentally friendly focus, the product provides considerable energy efficiency, minimizing operating costs while maximizing output. Whether it’s upgrading existing systems or building new solutions, this heat exchanger offers unprecedented reliability and longevity, a real game-changer for thermal management technology.

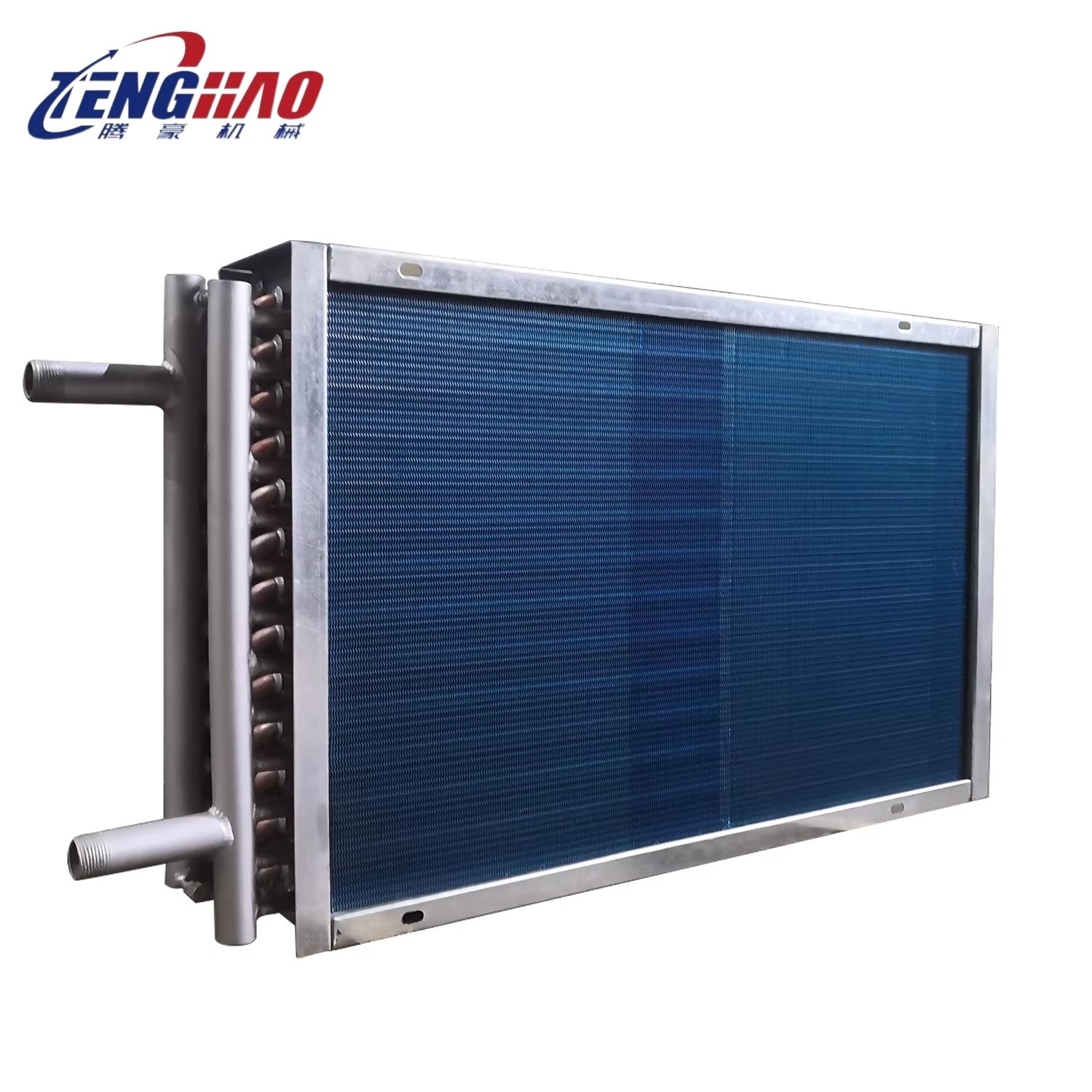

Wuxi Tenghao Machinery Manufacturing Co., Ltd's latest products further illustrate the commitment to sustainability and innovation. Wuxi Tenghao, the product in the heat exchange industry, outlines nearly a decade of groundbreaking research and development. With the help of the fin's tube structure, it optimizes the air heat exchange efficiency, making it an important part of energy-saving systems in various industrial fields such as environmental protection, chemicals, grains and oils, new energy sources, paper, paper and medicines.

Precision Engineering and Reliability

The carefully arranged fins of the rectangular fin air heat exchanger enhance heat transfer by promoting optimal air flow around the tube. Made of rugged aluminum, the heat exchanger has been carefully designed for durability and corrosion resistance, promising a lifetime in challenging environments. Each unit follows a strict design protocol supported by advanced heat exchanger software to ensure compliance with international standards such as ISO9001:2015, CE, EAC, etc.

This energy-efficient heat exchanger is essential for businesses that aim to reduce environmental footprint while maximizing operational efficiency. This product is in line with Wuxi Tenghao’s dedication to excellence, innovation and sustainability, setting a high benchmark in the heat exchange equipment industry. It promises to transform the industrial thermal management landscape, delivering exceptional performance and cost-effectiveness, confirming its position as an important tool for cutting-edge energy solutions worldwide.

In short, fin tube heat exchangers have exemplary design and performance, and are at the heart of the thermal management needs of various departments. Provides unparalleled efficiency and reliability that ensures sustainability and innovative excellence in an industrial context. As the industry continues to seek energy-efficient solutions, this advancement in heat exchanger technology provides the necessary tools to drive the future of heat management with confidence.