The Revolution of Energy-Saving Heat Exchangers an Introduction

In today's industrial landscape, the demand for higher efficiency and reduced energy consumption is paramount. Central to achieving these goals are advanced thermal management solutions, with the Energy-Saving Heat Exchanger leading the charge. These devices are critical in optimizing energy use across various sectors, and among the most innovative designs is the Finned Tube Heat Exchanger, which significantly enhances thermal performance and promotes sustainability. This technology is not merely an upgrade; it represents a fundamental shift in how industries approach heat management and energy conservation, paving the way for more efficient and environmentally responsible operations.

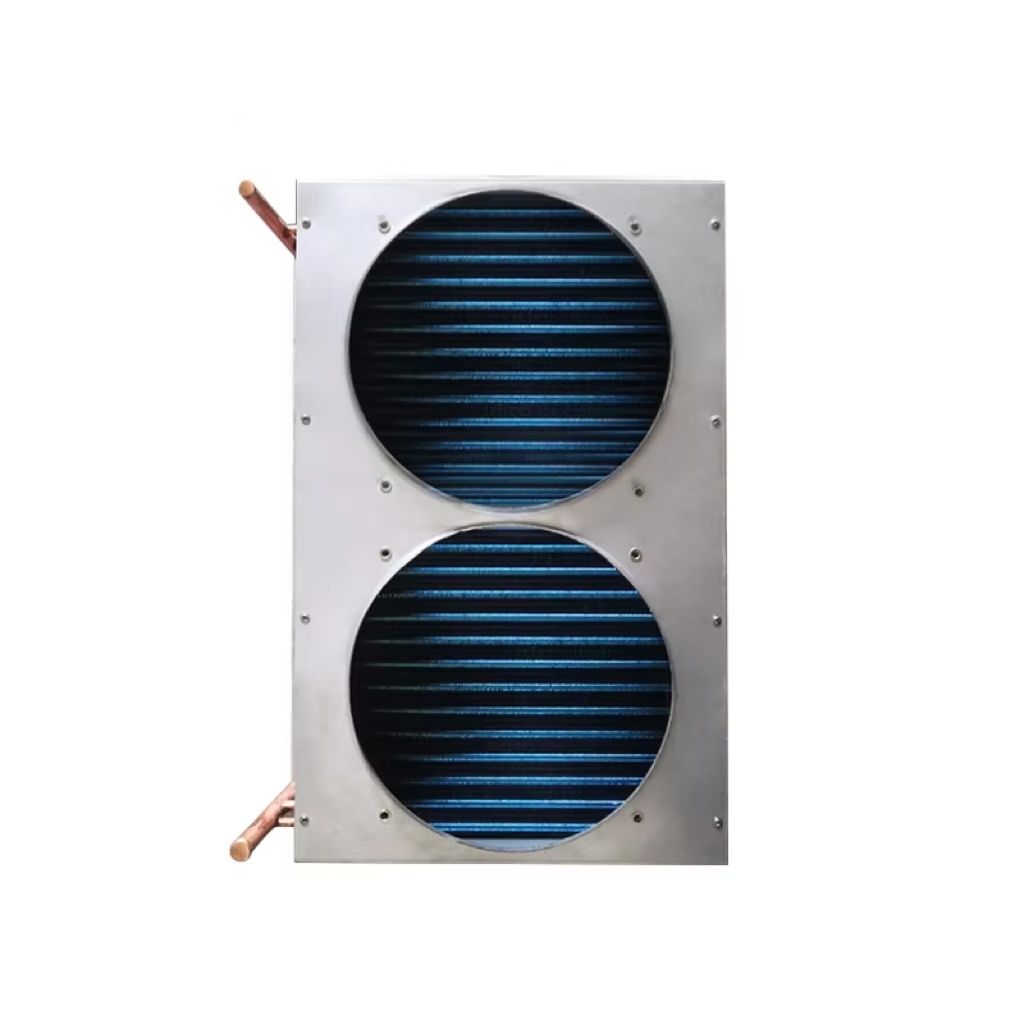

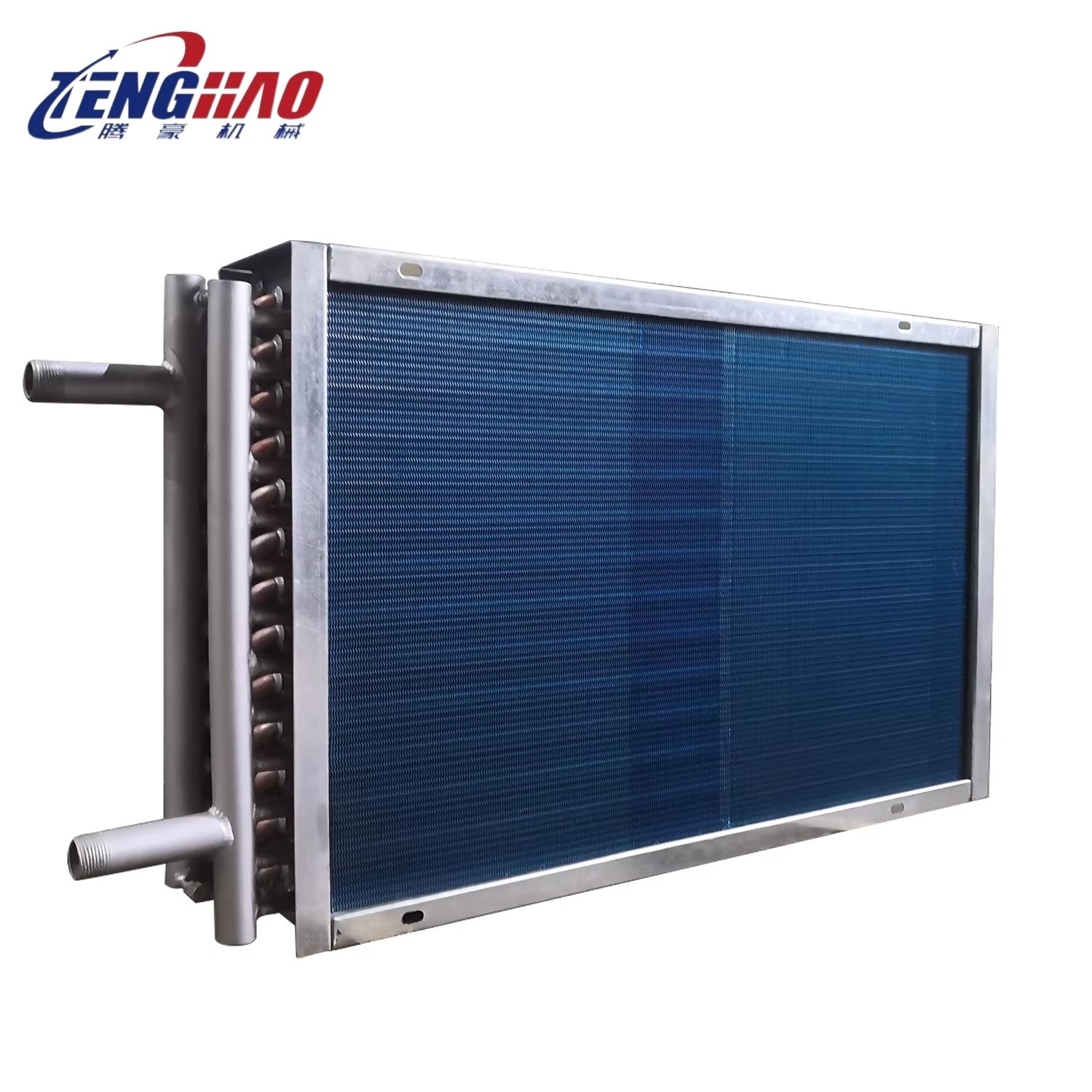

Engineering Excellence in Finned Tube Design

The core of an effective Energy-Saving Heat Exchanger often lies in its meticulous design, particularly when it involves Finned Tube Technology. Each finned tube is a product of precision engineering, available in various materials to suit specific operational demands. For environments prone to corrosion, options like Stainless Steel (304/316/316L) offer robust resistance. Carbon Steel is the material of choice for high-temperature, high-pressure scenarios, capable of enduring temperatures up to 450°C. For applications requiring lightweight construction and superior thermal conductivity, such as refrigeration and HVAC systems, Aluminum or Copper tubes are ideal. The fin design itself is crucial; high-frequency welded fins ensure exceptional bonding strength for durability, while helical wound fins with optimized pitches enhance airflow management and Heat Transfer Efficiency. The Steel-Aluminum Composite option further provides a balanced solution, combining cost-effectiveness with remarkable strength, embodying the best of Heat Exchanger Design.

Maximizing Thermal Performance and Energy Efficiency

The true measure of an advanced heat exchanger is its ability to deliver superior Thermal Performance and Energy Efficiency. Modern finned tube designs boast impressive heat transfer coefficients, often reaching 800-1,200 W/(m²·K), which can be 30-50% higher than conventional counterparts. A thermal efficiency rate of around 92% makes these units an indispensable asset in reducing energy consumption, potentially saving between 25% to 40% on energy costs. A key factor in this enhanced performance is the significant expansion of the surface area; fins can increase the heat exchange surface by 15 to 30 times compared to bare tubes. This allows for maximized heat transfer within a more compact footprint, a critical advantage in space-constrained installations and a testament to efficient Finned Tube Technology.

Versatility Across Diverse Operating Conditions

A hallmark of a well-designed Energy-Saving Heat Exchanger is its adaptability to a wide array of working environments and media. These advanced Finned Tube Heat Exchanger units can operate effectively across a broad temperature spectrum, typically from -50°C to +600°C, making them suitable for extreme conditions. They are compatible with various fluids, including gases like air, steam, and nitrogen, as well as liquids such as oil, water, and diverse chemical solutions. Moreover, they can handle phase-change media, which maximizes thermodynamic efficiency. Pressure ratings are also a strong suit, with capabilities supporting up to 16 MPa for tube-side applications and 10 MPa for shell-side applications, rendering them suitable for many Industrial Heat Exchangers requirements.

Customization and Advanced Features

To meet the specific needs of diverse applications, customization is key. Fin geometry can be tailored; for instance, serrated fins can enhance heat transfer by an additional 20-30%, while lanced fins are designed to lower air resistance and reduce pressure drops. Specialized coating options, such as hydrophobic coatings for condensation control or anti-corrosion layers like PTFE, extend the product's lifespan and maintain performance. Furthermore, the integration of smart sensors and controls, including variable frequency drives (VFD) and precise temperature sensors, allows for optimized operation and continuous monitoring, ensuring peak Heat Transfer Efficiency and operational reliability. These customizable features ensure that the Heat Exchanger Design is perfectly aligned with the user's specific operational goals.

Broad Applications in Key Industries

The benefits of these advanced Energy-Saving Heat Exchangers are realized across a multitude of industries. In HVAC systems, they contribute to more efficient climate control. Power plants utilize them for waste heat recovery and optimizing generation cycles. Chemical processing facilities rely on their corrosion resistance and ability to handle aggressive media. Refrigeration units benefit from compact plate-fin solutions designed for ultra-low temperature environments. Their space-saving designs, which can reduce installation footprints by up to 40%, make them invaluable for retrofitting existing facilities or designing new, compact installations. This versatility makes them a cornerstone of modern Industrial Heat Exchangers and effective Heat Recovery Systems.

Driving Sustainability and Environmental Responsibility

Beyond operational efficiency, the adoption of Energy-Saving Heat Exchangers, particularly those incorporating sophisticated Finned Tube Technology, plays a crucial role in promoting environmental sustainability. These systems contribute significantly to reducing CO₂ emissions; for example, a 1,000 kW unit can save up to 3 tons of CO₂ per year. The high thermal recovery rate, often reclaiming 70-95% of waste heat, means less fuel consumption and a smaller carbon footprint. Compliance with stringent industry standards like ASME BPVC, ISO 50001, and CE certifications underscores their quality, reliability, and commitment to responsible manufacturing. Investing in such technology is not just an industrial upgrade but a decisive step towards a cleaner, more sustainable future, enhancing overall Energy Efficiency and supporting comprehensive Heat Recovery Systems.